Method and fixture for controlling turning deformation of ultra-thin wall aluminum alloy high-precision nozzle sealing groove

An aluminum alloy, high-precision technology, used in turning equipment, manufacturing tools, turning equipment, etc., can solve problems such as batch scrap, deviation from design requirements, process technology bottlenecks, etc., to reduce nozzle profile errors and improve the surface of parts. Quality, avoid the effect of clamping deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings, but the claimed protection scope is not limited to the description.

[0028] like Figure 5 and Image 6 As shown, the routine processing of parts of this product is prone to dimensional deformation out of tolerance, and the surface roughness of the product is unqualified. The following scheme is adopted:

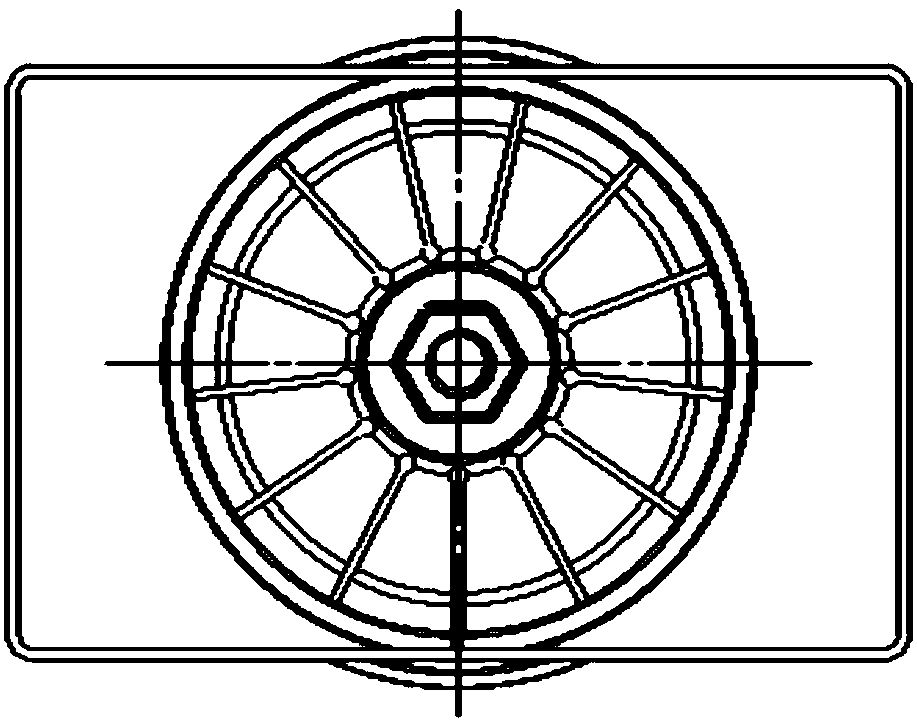

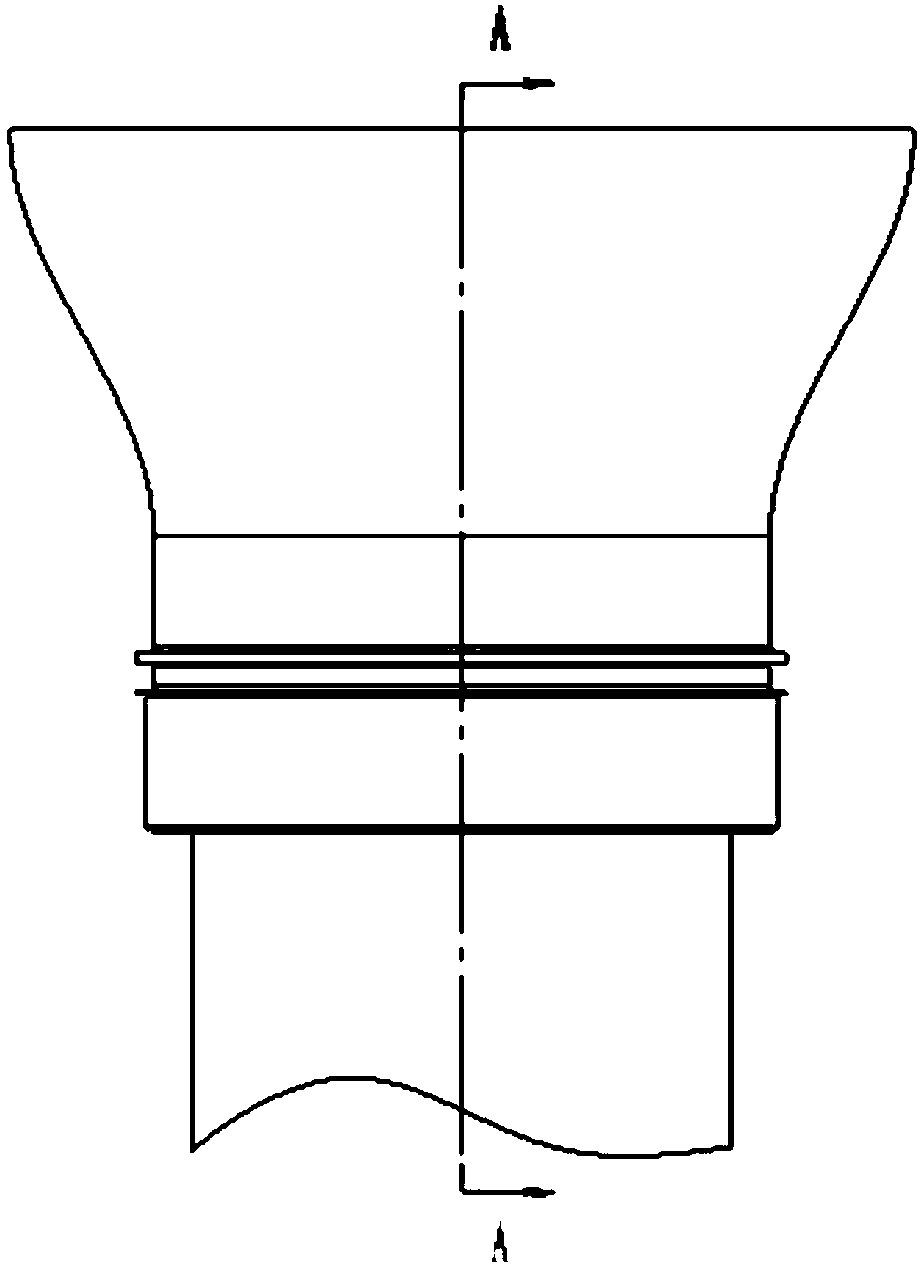

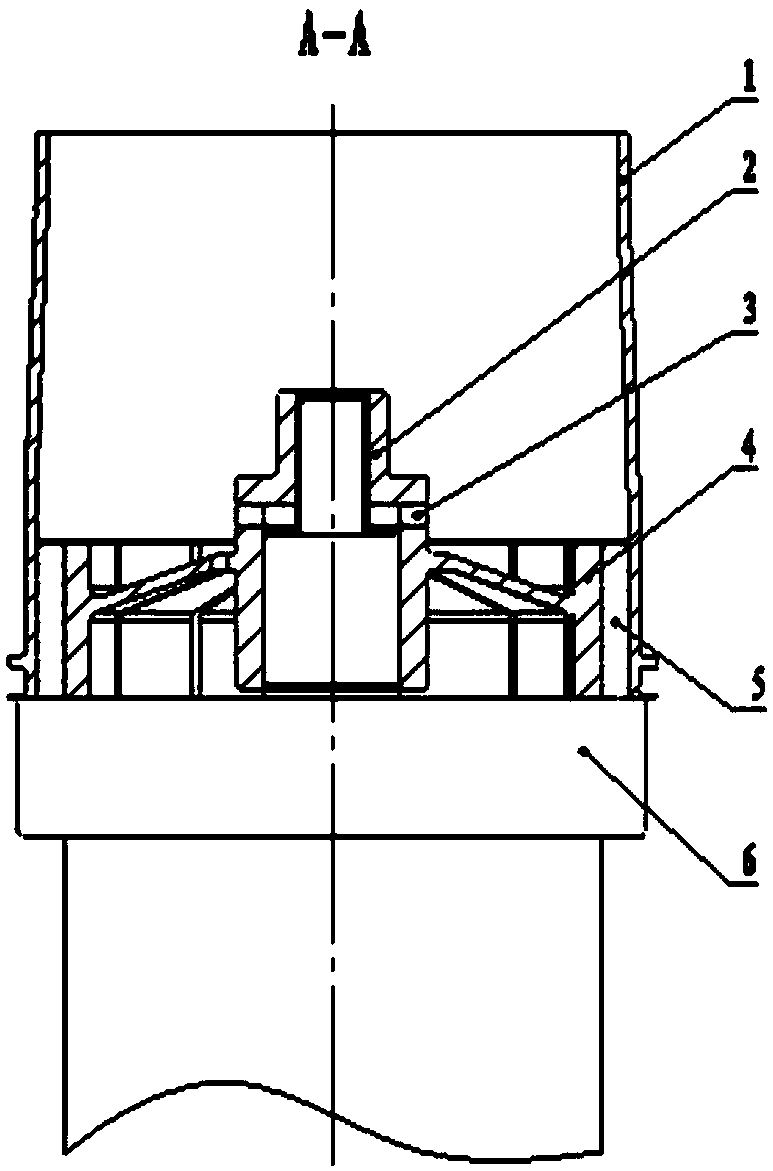

[0029] Design and manufacture a set of high-precision large-capacity expansion fixtures, such as figure 1 , Figure 1a and Figure 1b As shown, the ultra-thin-walled aluminum alloy high-precision nozzle sealing groove turning fixture includes an elastic expansion sleeve support body 4 with a continuously variable outer diameter, an opening expansion ring 5 and a clamp body 6; the elastic expansion sleeve support body 4 and the clamp body 6 can be Disassembly and connection; the opening expansion ring 5 is placed on the outer peripheral surface of the elastic expan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com