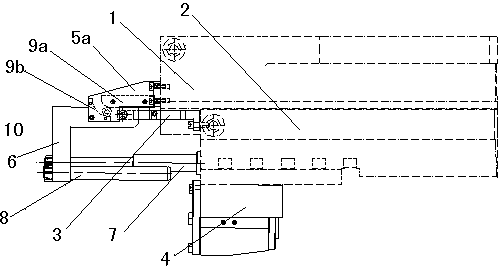

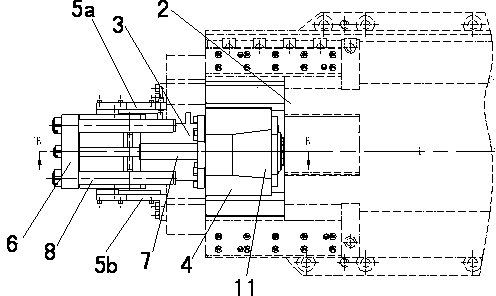

Automatic Clamping and Relaxing Mechanism for Small Bracket of Hobbing Machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

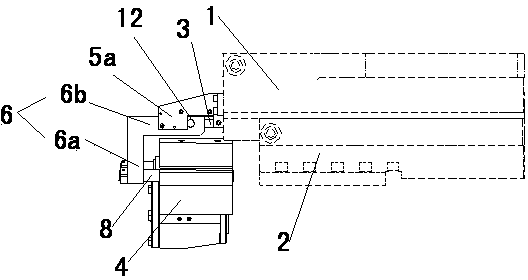

Embodiment 2

[0033] The difference between this embodiment and Embodiment 1 is that the mechanism of the guide mechanism is different: in this embodiment, the guide mechanism includes guide grooves arranged on the upper support plate 5a and the lower support plate 5b, and the upper surface and the lower surface of the support seat 6 A guide bearing 10 or a transmission shaft is provided, and the guide bearing 10 or the transmission shaft rolls along a curve in the guide groove. Preferably, the guide bearing or the transmission shaft rolls along a straight line and then an arc in the guide groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com