Linear type laser-beam welding machine of capacitance battery and welding method of linear type laser-beam welding machine

A laser welding machine and capacitor battery technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of short service life of the welding head, difficult to implement resistance welding, large heat of the workpiece, etc., to reduce labor intensity and cost, improve automation efficiency, and the effect of reasonable process layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

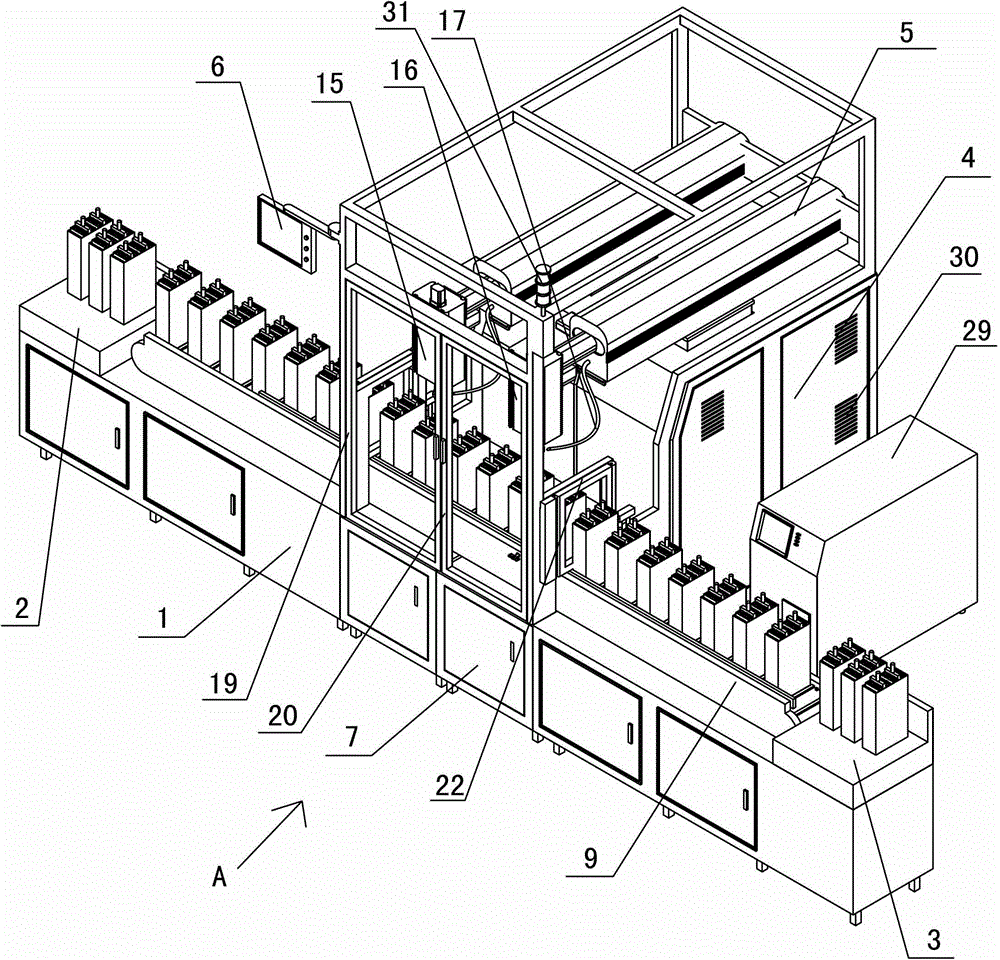

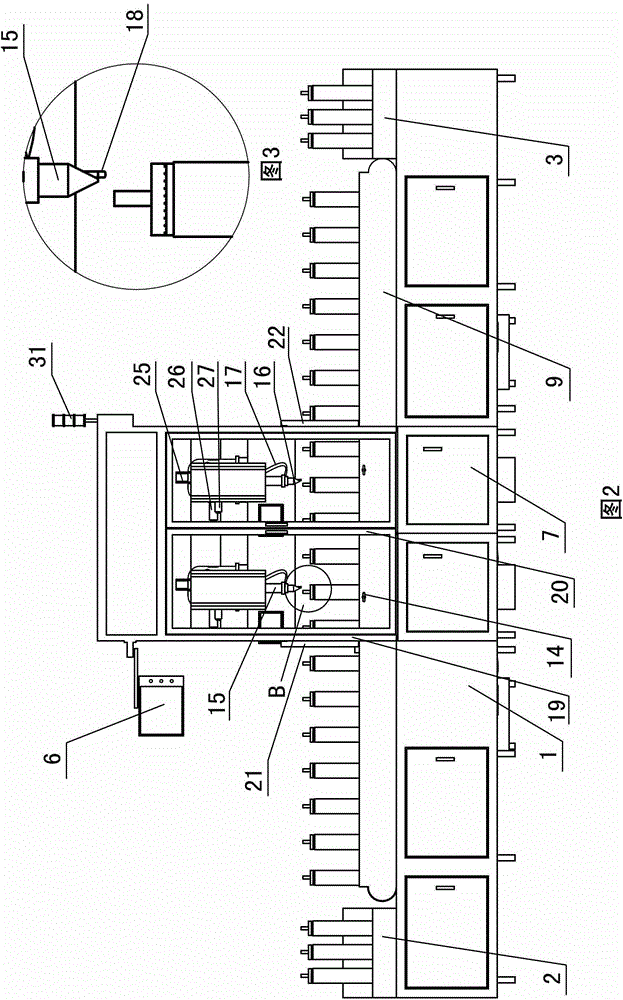

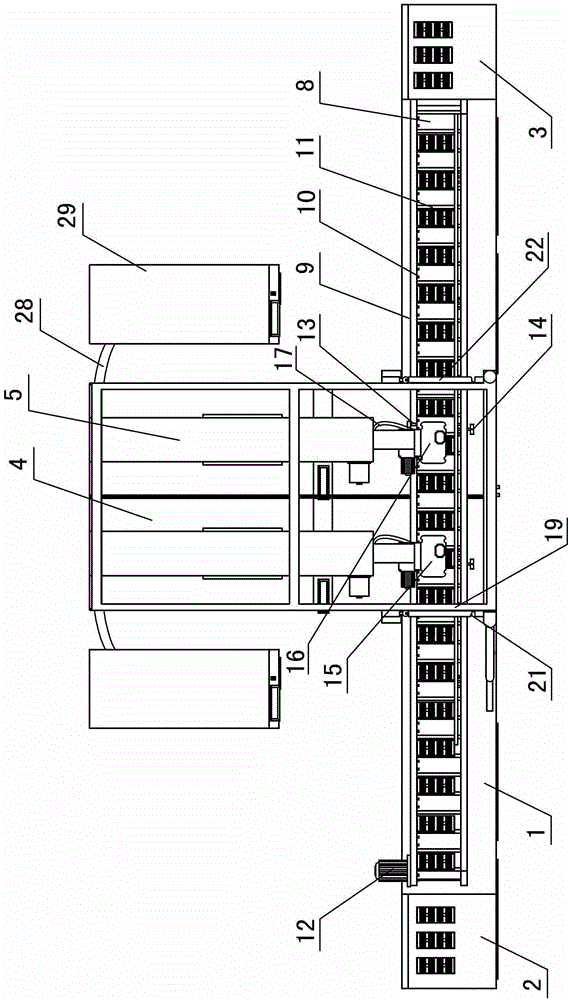

[0036] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0037] Such as Figure 1~5 As shown, the workbench 1 is provided with a front placement platform 2, a transmission device, and a rear placement platform 3 in sequence. The transmission device is provided with multiple sets of battery positioning devices. One side of the workbench 1 is provided with a laser welding host 4. The laser welding host The top of 4 is equipped with x, y, z-axis displacement mechanism 5, and the front end of x, y, z-axis displacement mechanism 5 is equipped with a welding mechanism, the welding mechanism is located directly above the transmission device, and the workbench 1 is provided with a control panel 6, A functional control module is arranged in the control panel 6 , an electrical control cabinet 7 is installed in the workbench 1 , and the control panel 6 is respectively connected with the transmission device, the welding mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com