Rotary die core control device for unscrewing metallic die

A control device and a technology for rotating molds, applied in the field of rotating mold core control devices, can solve problems such as prolonging cycle time, and achieve the effect of shortening cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

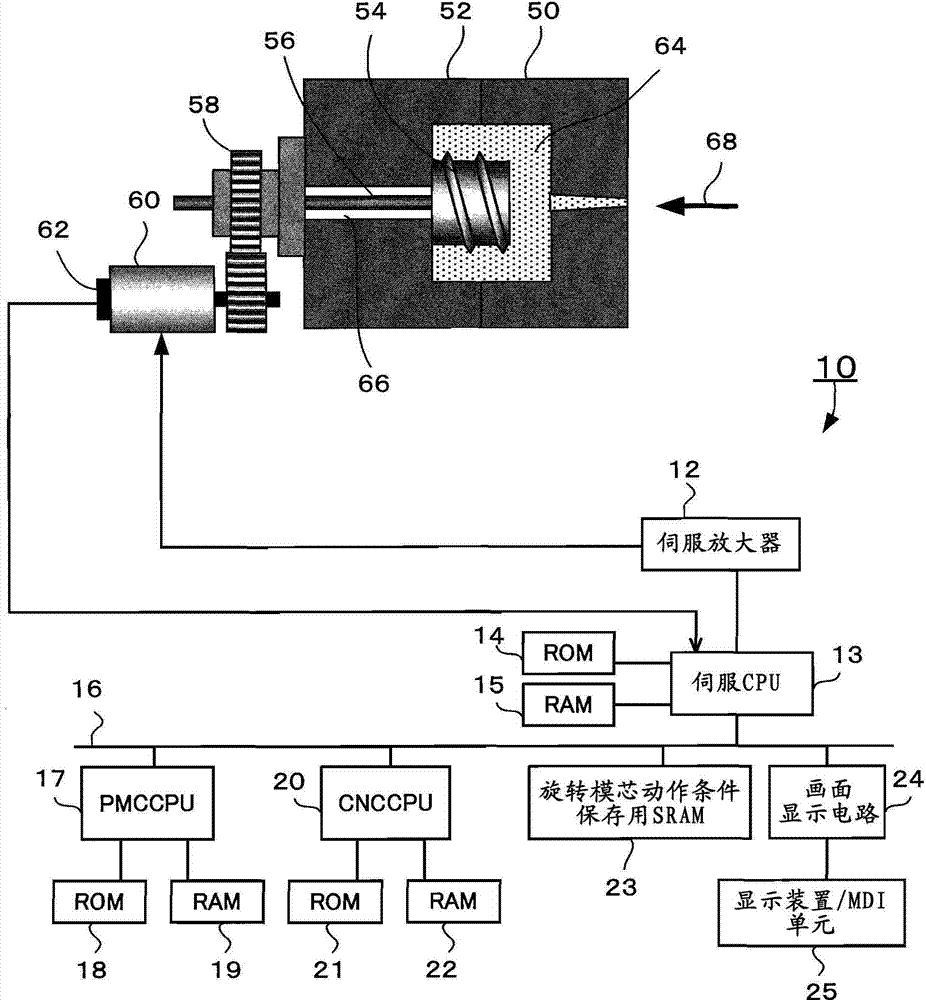

[0026] First, a schematic structure of a conventional injection molding machine (not shown) will be described. The injection molding machine has a clamping part and an injection part on the machine table. The injection part heats the molten resin material (pellet) and injects the molten resin into the cavity of the mold. Install the nozzle on the front end of the injection cylinder, and insert the screw through the injection cylinder. A hopper for supplying a resin material into the injection cylinder is attached to the upper portion of the injection cylinder.

[0027] The mold clamping section mainly opens and closes molds (fixed side molds, movable side molds). The mold clamping section includes a fixed plate on which the fixed side mold is mounted, a movable plate on which the movable side mold is mounted facing the fixed side mold, and a servo for opening and closing the mold that moves the movable plate forward and backward in the direction of the injection section. A ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap