Method for laminating leather, and leather seat using same

A technology of leather and ventilation holes, applied in the field of leather seats, can solve problems such as difficulties and hinder continuous production, and achieve the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

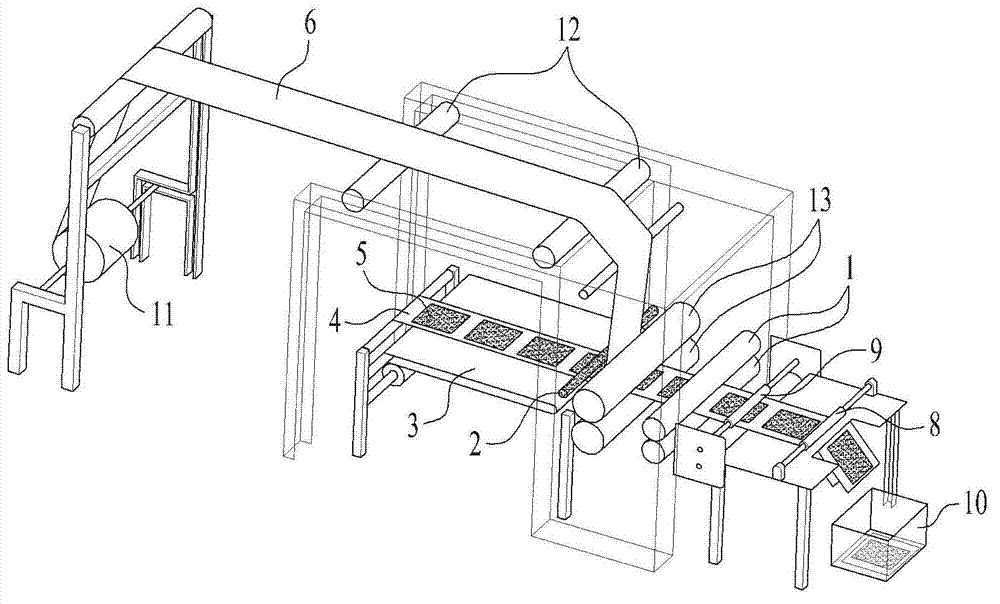

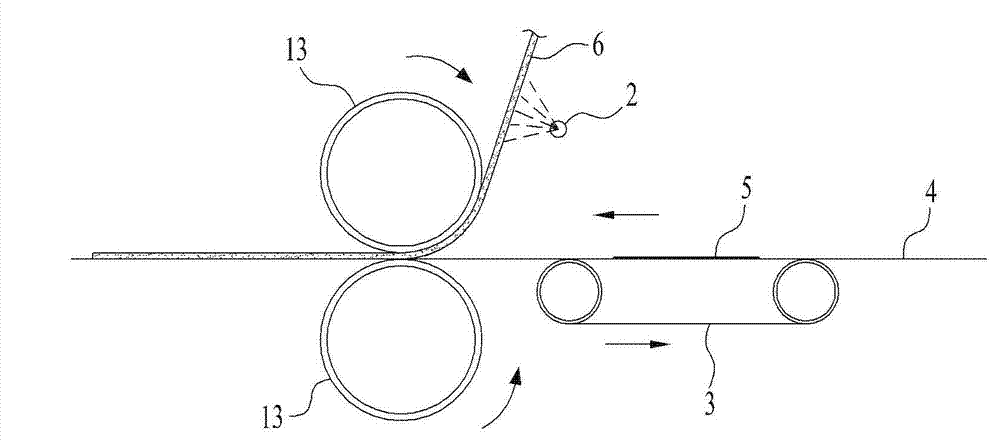

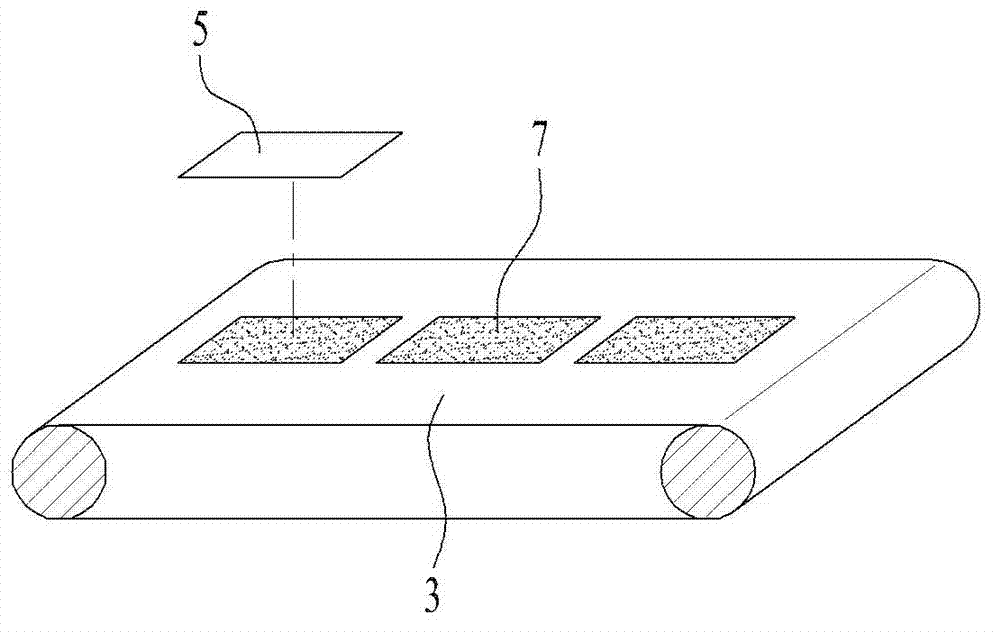

[0025] figure 1 is a perspective view schematically showing a leather lamination apparatus according to an embodiment of the present invention. figure 2 is a view schematically showing the overall process of laminating leather sheets according to an embodiment of the present invention. image 3 is a view showing marking a cut shape on a conveyor belt and setting a leather piece on a separation paper piece according to an embodiment of the present invention. Figure 4 is a flowchart illustrating a method of laminating leather sheets according to an embodiment of the present invention.

[0026] see figure 1 with 2 , The leather lamination apparatus according to the embodiment includes a sponge roll 11 for continuously feeding the sponge 6 wound thereon, a guide roller 12 for guiding the sponge 6, a horizontal workbench 3 with a conveyor bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com