Moving mechanism around pipeline

A motion mechanism and pipeline technology, applied in the field of ring-pipe motion mechanism, can solve the problems of inability to continuously operate multiple pipes, poor passability, etc., and achieve the effects of good passability, less space requirements around the pipes, and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

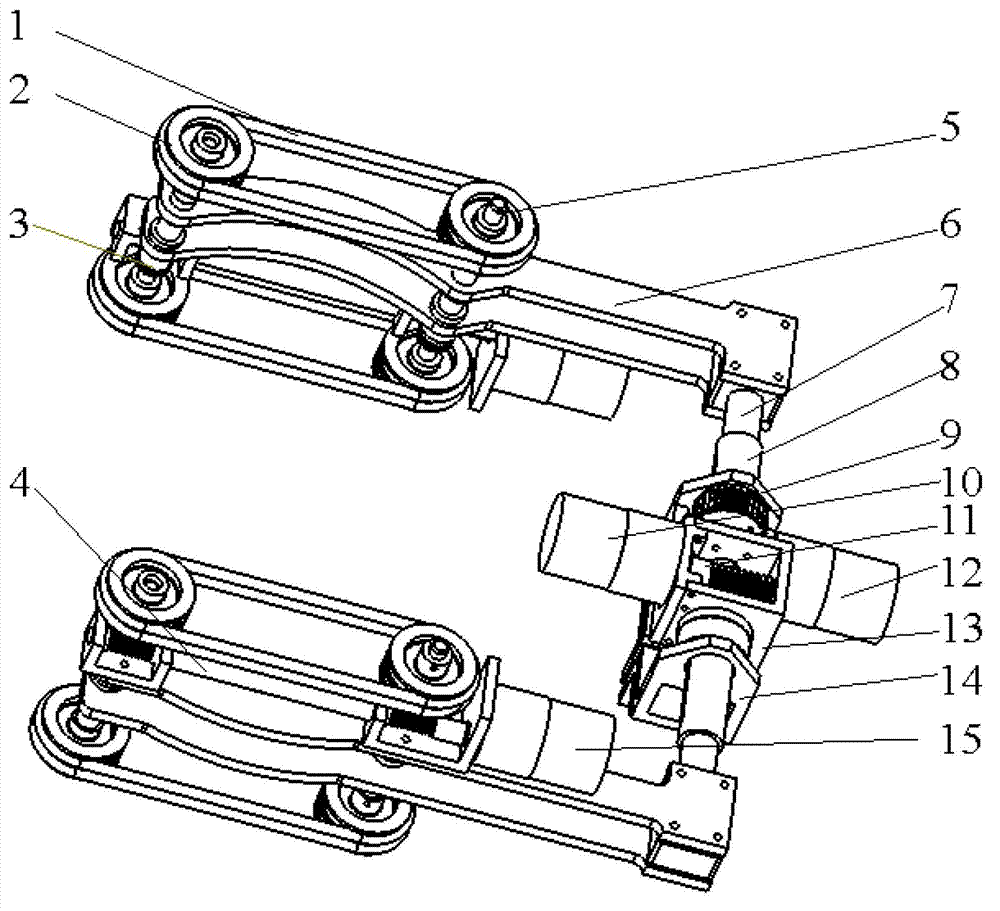

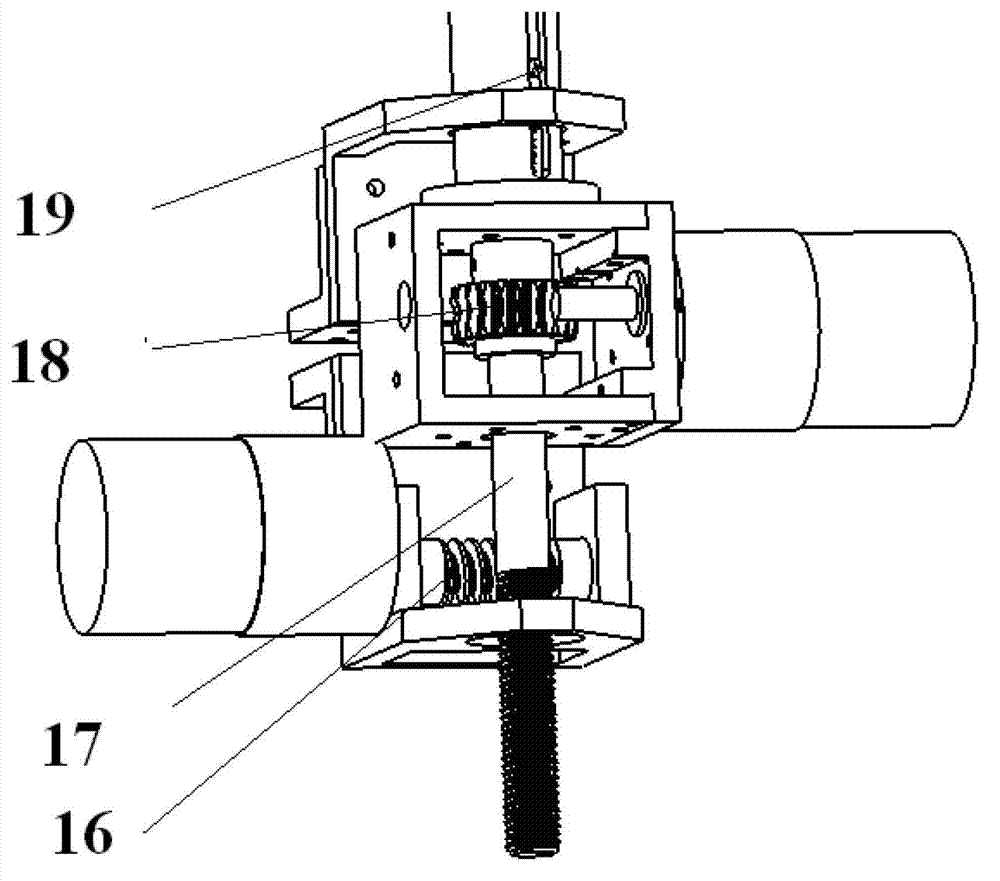

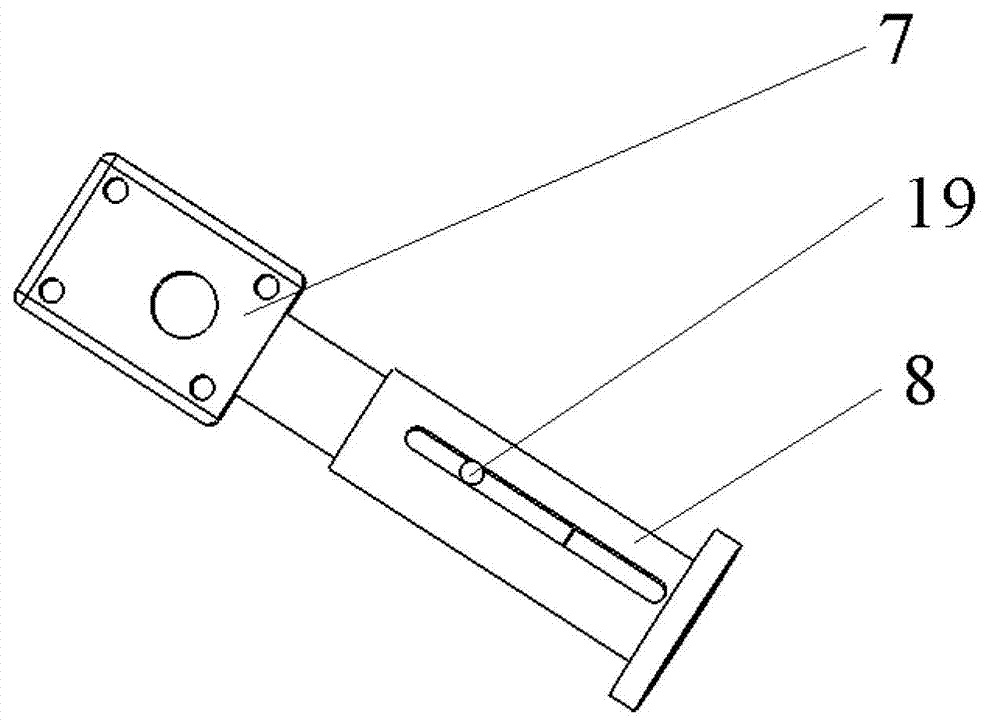

[0016] see Figure 1 ~ Figure 4 , a circular pipeline movement mechanism, including a bracket 14, on which a bidirectional lead screw 17 rotatably connected to the bracket 14 is connected, and two screw nuts 7 arranged symmetrically up and down and opposite in direction of rotation are connected to the bidirectional lead screw 17 , the screw nut 7 is provided with a guide sleeve 8, the guide sleeve 8 is fixedly connected on the telescopic motor frame 13, the guide sleeve 8 is provided with a chute parallel to its center line, and the chute is provided with The pin 19 fixed on the nut 7, the outer end of the nut 7 is provided with an overturn arm 6 perpendicular to it; the bidirectional lead screw 17 is equipped with a first worm wheel 18, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com