Automatic drawing method applicable to wheel set assemblies with gearboxes and motors

An automatic extraction and gearbox technology, applied in the field of stacker, can solve the problems of low space utilization, large floor area, and inability to adapt to special support requirements, and achieve the effect of improving space efficiency and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

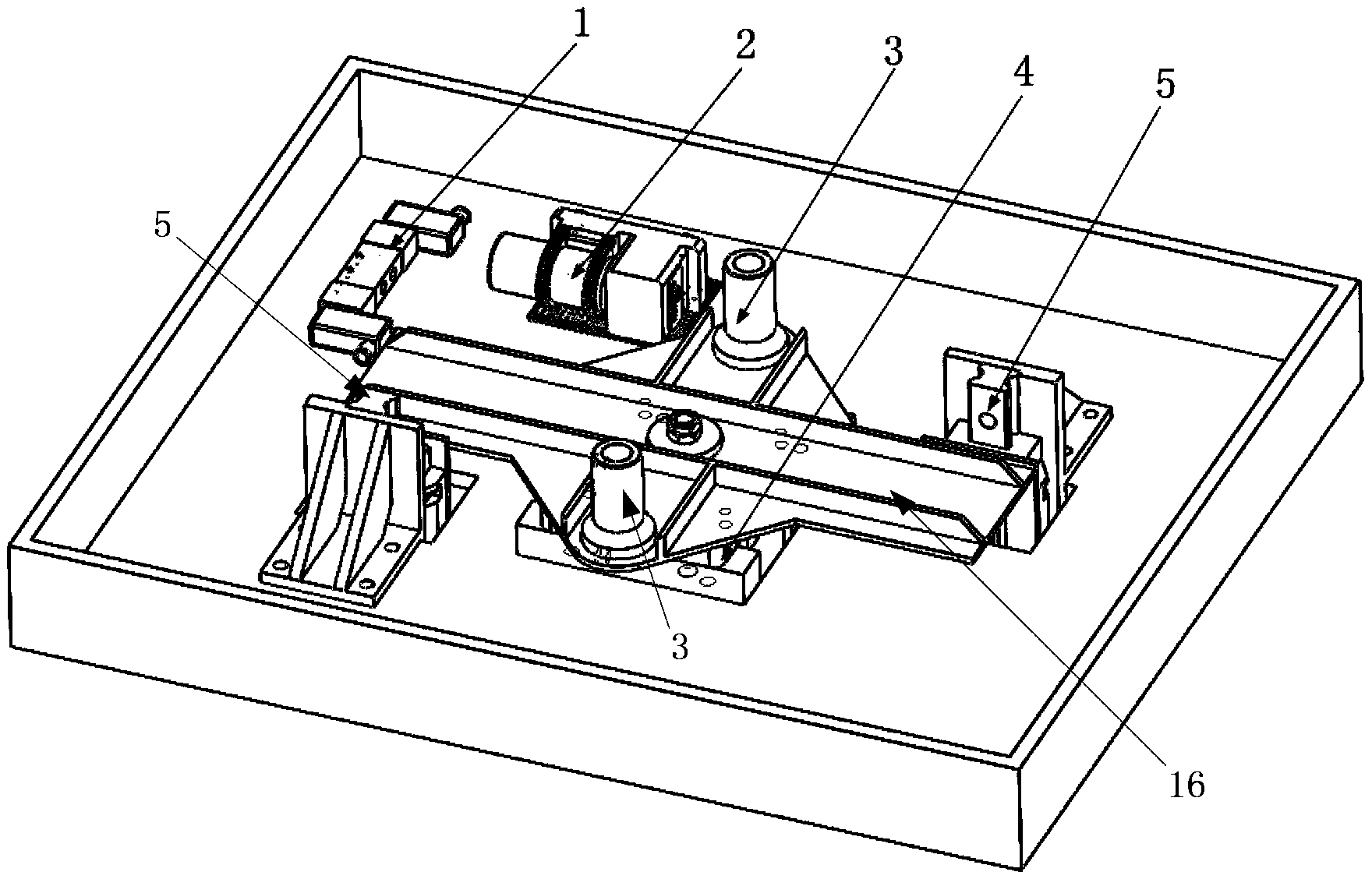

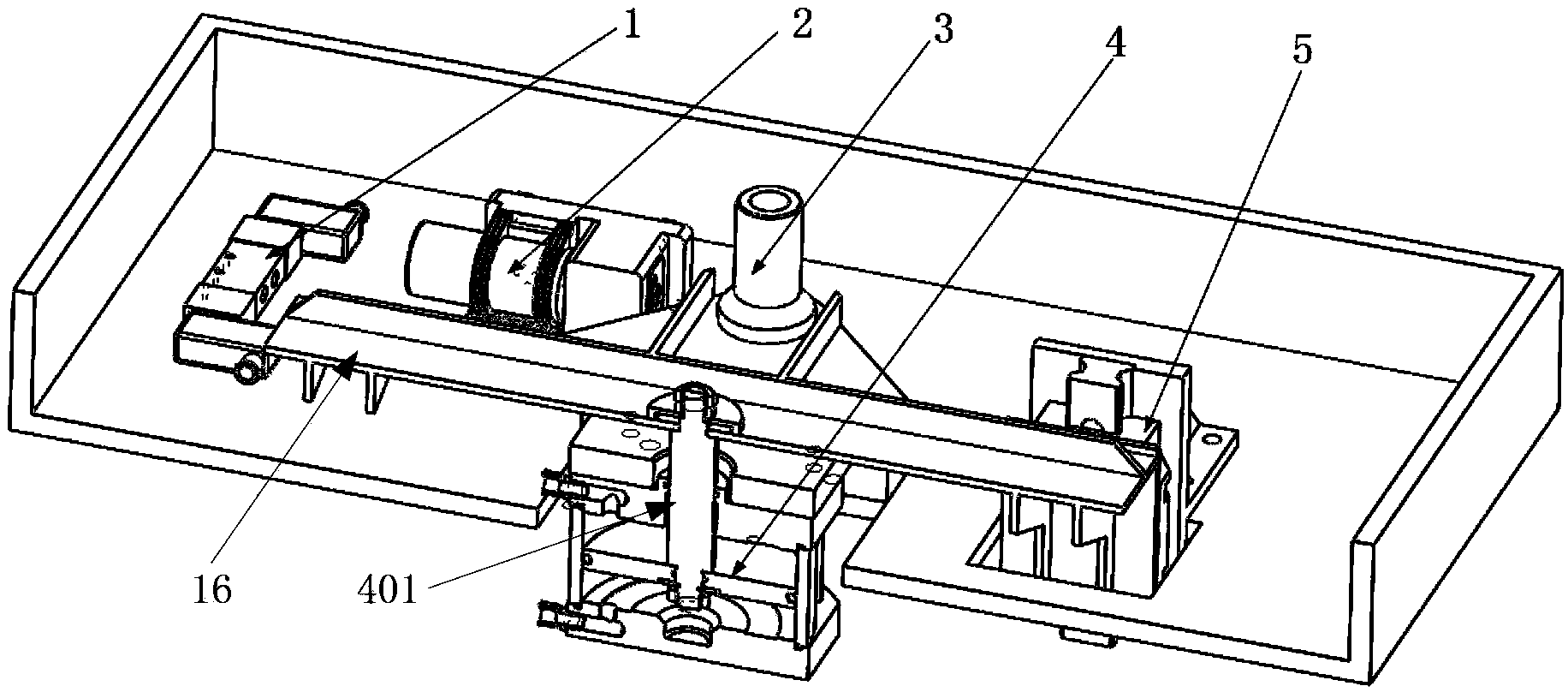

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

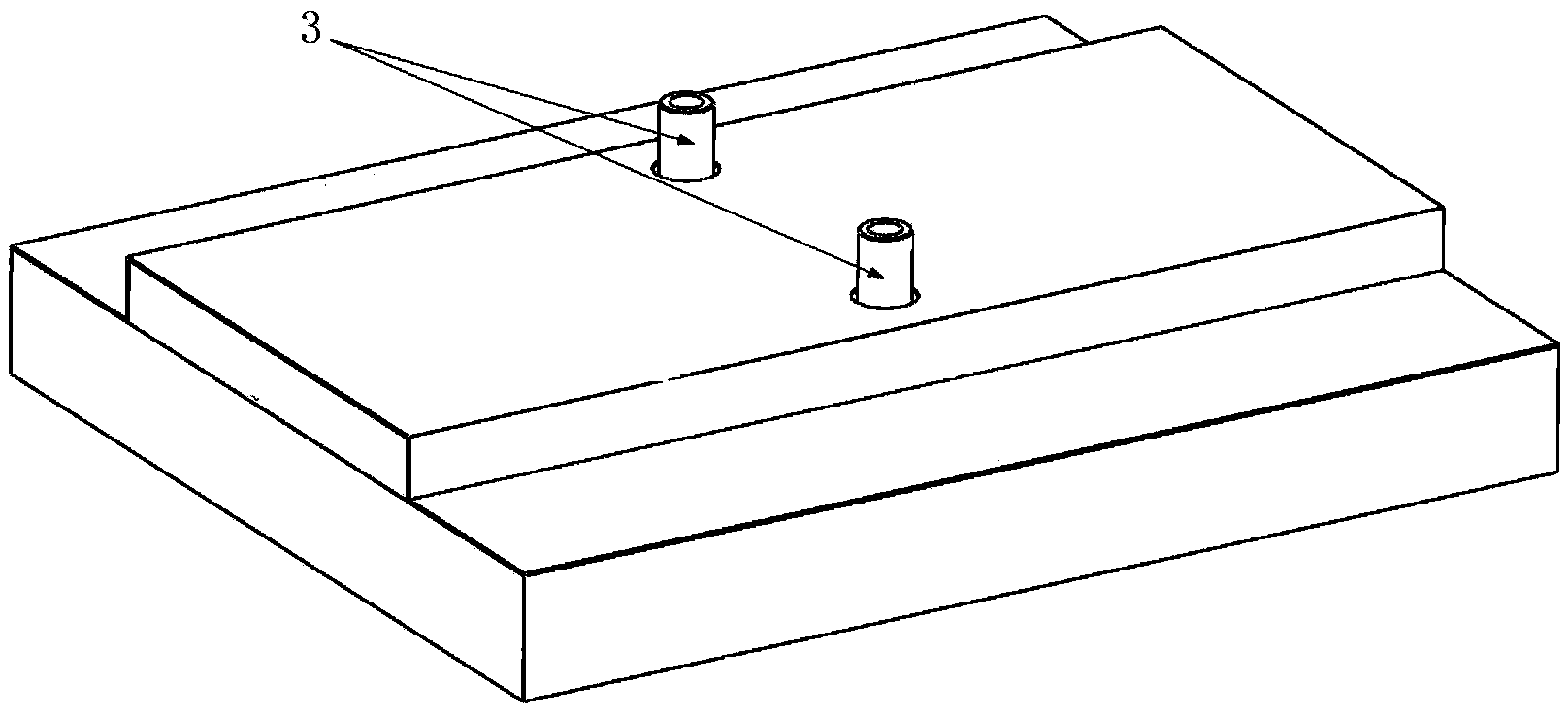

[0029] The invention provides an automatic extracting device and an extracting method suitable for a whole wheel set with a gear box and a motor. The key technology to realize the automatic extraction function of the whole wheel set with gearbox and motor lies in two aspects. On the one hand, the wheel set part must have a support trolley in the form of special support, and the support trolley that supports the gearbox and motor at the same time has the features to be extracted. (extraction hole 9). On the other hand, the automatic extraction device on the stacker equipment must be able to cooperate with the extracted features of the support trolley to complete the automatic extraction work. The automatic extraction device on the stacker cooperates with the supporting trolley to adapt to the different forms of wheel sets with gearboxes and motors bei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com