Steam-driven three-dimensional physical simulation system for thick oil horizontal well

A technology of three-dimensional physics and simulation system, applied in the field of three-dimensional physical simulation system for steam flooding of heavy oil horizontal wells, which can solve the problems of low pressure, few temperature measurement points, and insignificant guiding role of on-site reservoir management, etc., and achieves easy laboratory operation, safe The effect of strong reliability and strong layout theory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are listed below and described in detail in conjunction with the accompanying drawings.

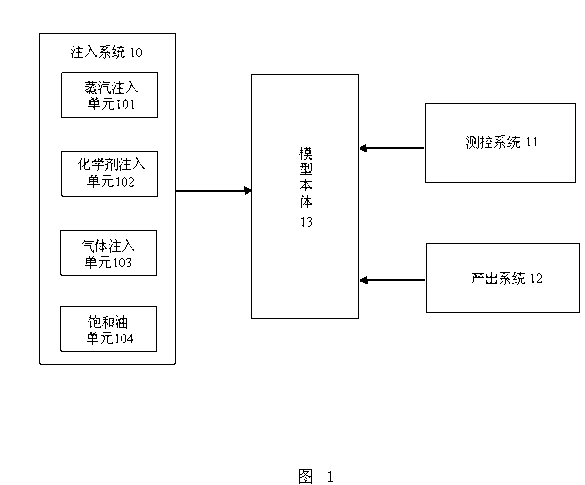

[0023] Such as figure 1 as shown, figure 1 It is a structural diagram of the three-dimensional physical simulation system for heavy oil horizontal well steam flooding of the present invention. The three-dimensional physical simulation system for heavy oil horizontal well steam flooding consists of an injection system 10, a measurement and control system 11, an output system 12 and a model body 13, and the entire model is placed on a rotatable model support. The injection system 10 is used to inject steam, chemical agent, gas and saturated oil into the model body 13 to ensure the smooth realization of different injection methods and different injection parameters. The injection system 10 is composed of a steam injection unit 101, a chemical agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com