Parallel construction method for shield arrival tunnel portal ring beam and shield crossing station

A technology for receiving holes and shield tunneling, which is used in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of long construction period, high cost, uncontrollable quality, etc. effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

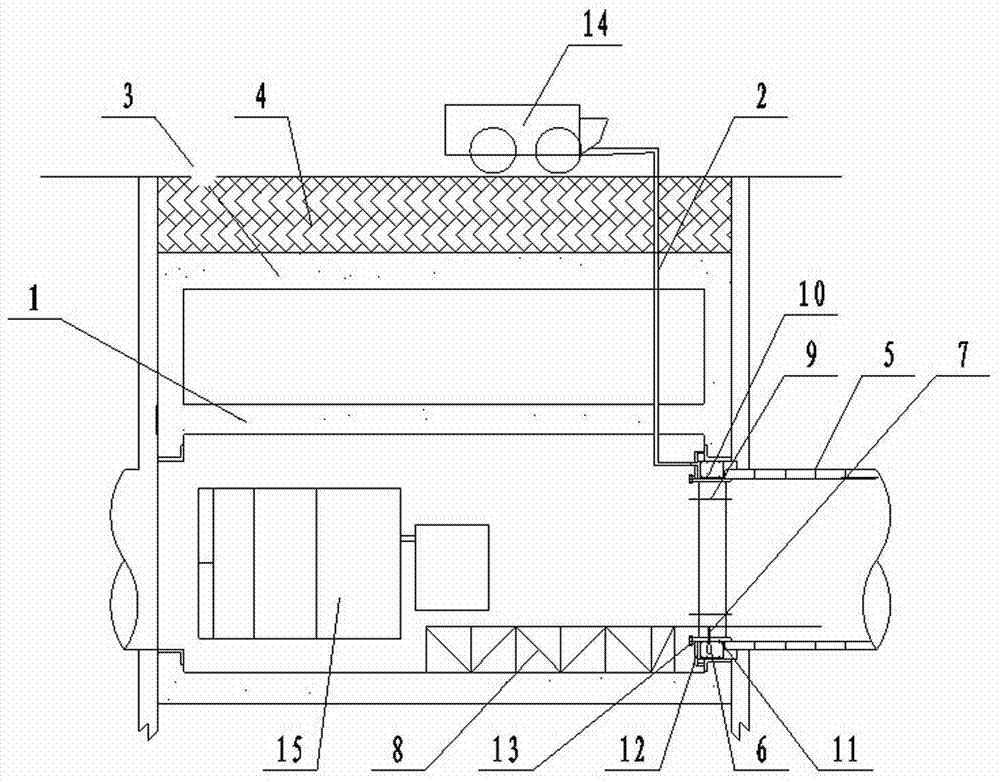

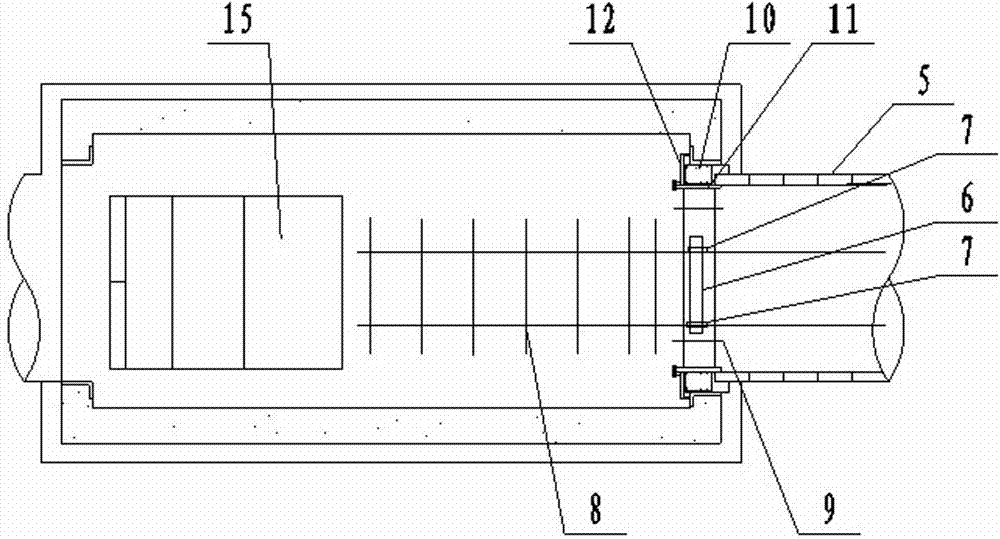

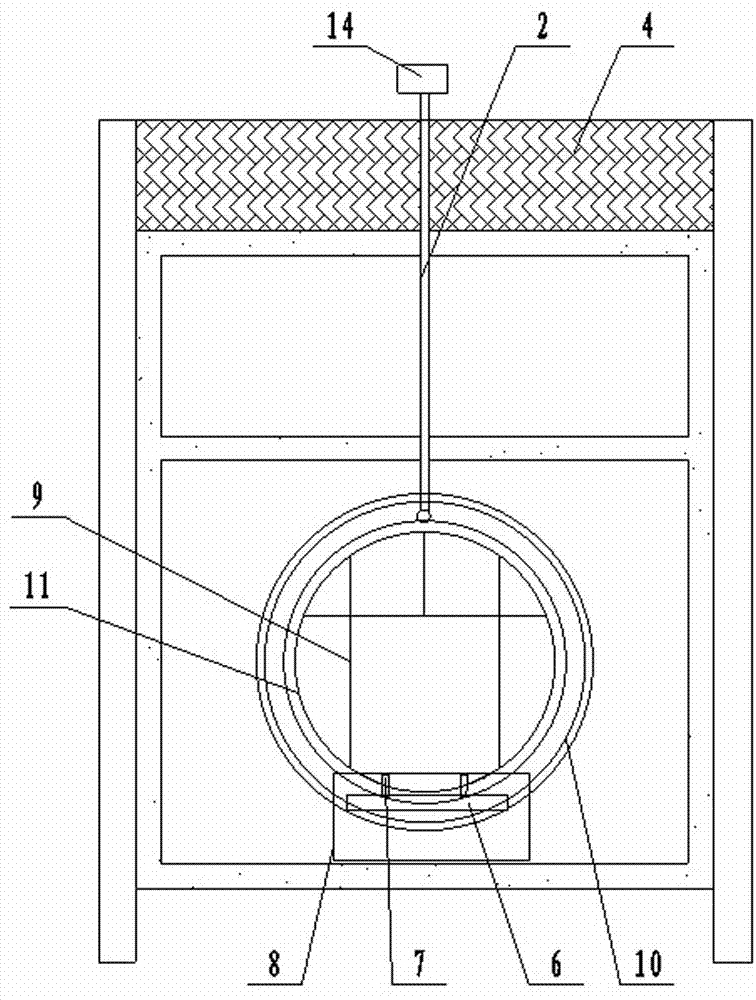

Method used

Image

Examples

example

[0037] Changsha Metro Line 2, No. 7, three shield sections, the shield needs to pass the station twice. In Yingbin Road Station and Furong Square Station, polyurethane is used to carry out secondary grouting on the shield receiving segment, canceling Zero ring segment assembly. It is used to install I-beam and welded steel plate support rails on the steel ring of the portal to realize the synchronous operation of the construction of the portal ring beam and the shield tunneling. The pump pipes are pre-embedded in the middle plate and the roof, so that the station does not need to leave temporary hoisting openings, and the traffic can be resumed one year in advance. Now it has been extended to the construction of the receiving portals in the three shield sections of the 10th standard of Line 1, which has greatly improved the station and shield construction efficiency, proving that the technology is advanced, practical, flexible in construction process adjustment, and good in ec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com