Uniform water distribution device realizing variable flow of reverse-flow cooling tower

A technology for evenly distributing water and cooling towers, applied in water shower coolers, direct contact heat exchangers, heat exchanger types, etc. The effect of saving production cost, cheap price and uniform water distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

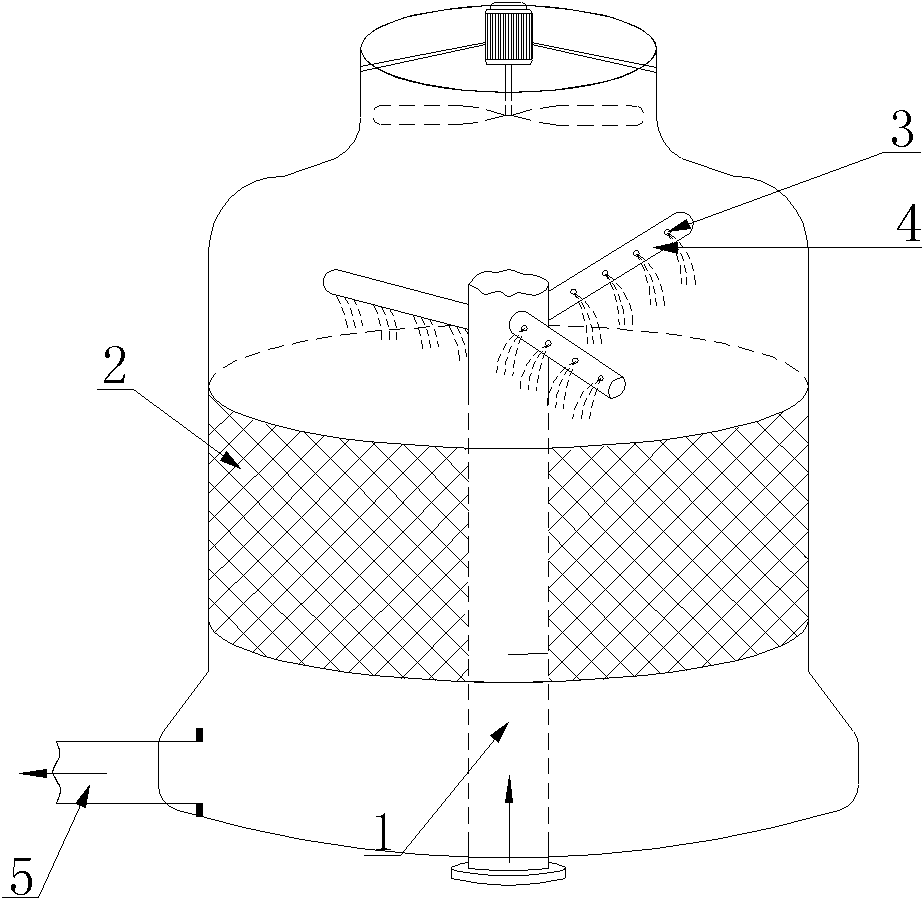

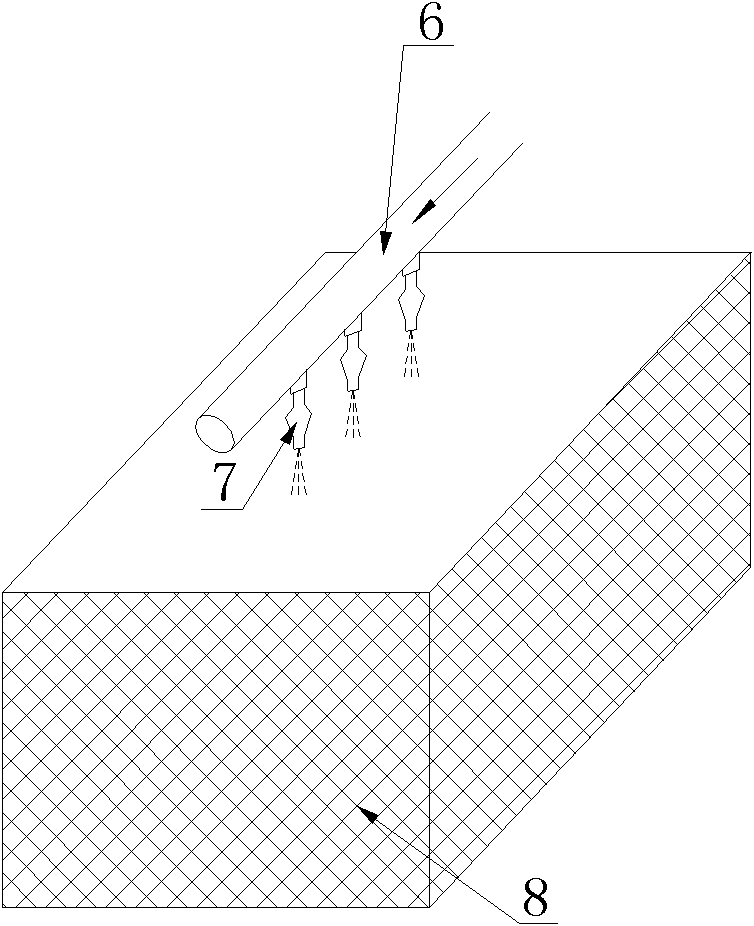

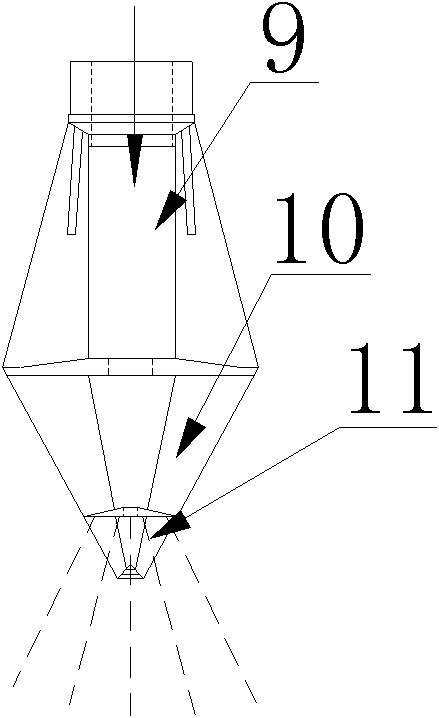

[0026] Such as image 3 As shown in the figure, a uniform water distribution device for counterflow cooling tower under variable flow is realized. It includes a water inlet pipe 1 and a horizontal water distributor. The water inlet pipe 1 is installed in the cooling tower body, and a horizontal water distributor is installed on the water inlet pipe 1. The horizontal water distributor includes a plurality of water distribution pipes 14 and water distribution nozzles 12, the water inlet of each water distribution pipe 14 is connected to the water inlet pipe 1, and a plurality of water distribution nozzles 12 are respectively installed on the body of the corresponding water distribution pipe 14. A plurality of water distribution nozzles 12 on the water pipe 14 are connected, and each water distribution nozzle 12 is higher than the water distribution pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com