Control method and system of self-adaptation hosiery machine

A control method and technology of a control system are applied in the fields of automatic control of socks machine, automatic knitting control system of socks machine, and knitting control of socks patterns, which can solve the problems of disordered control instructions, inability to achieve quality effects, user losses, etc., and improve production. Efficiency, reducing workload and technical difficulty, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

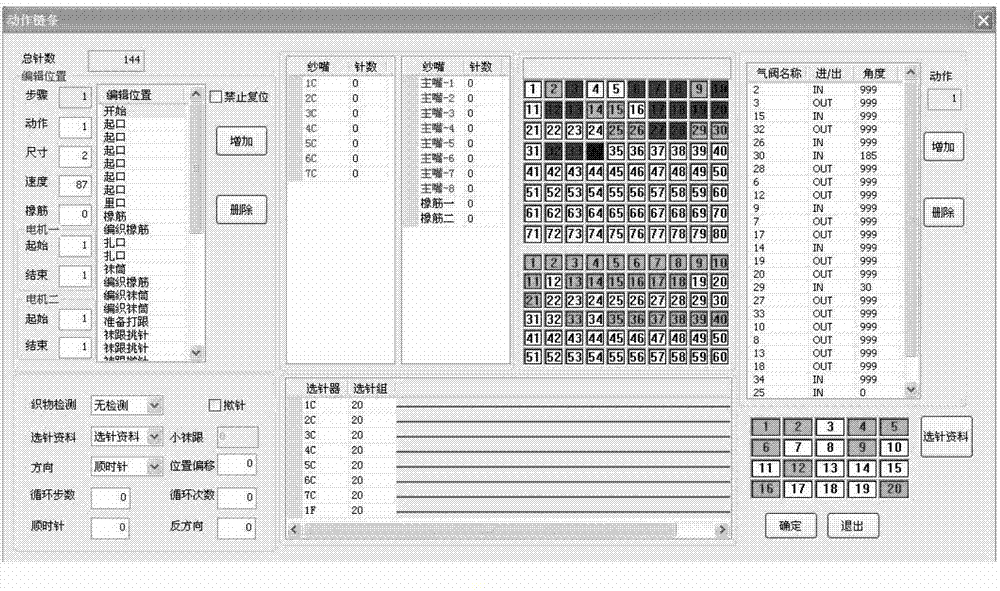

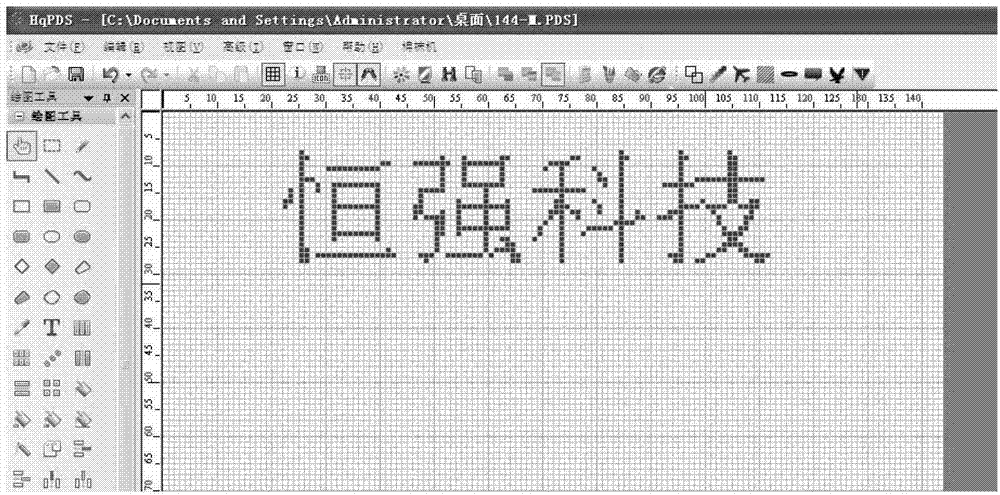

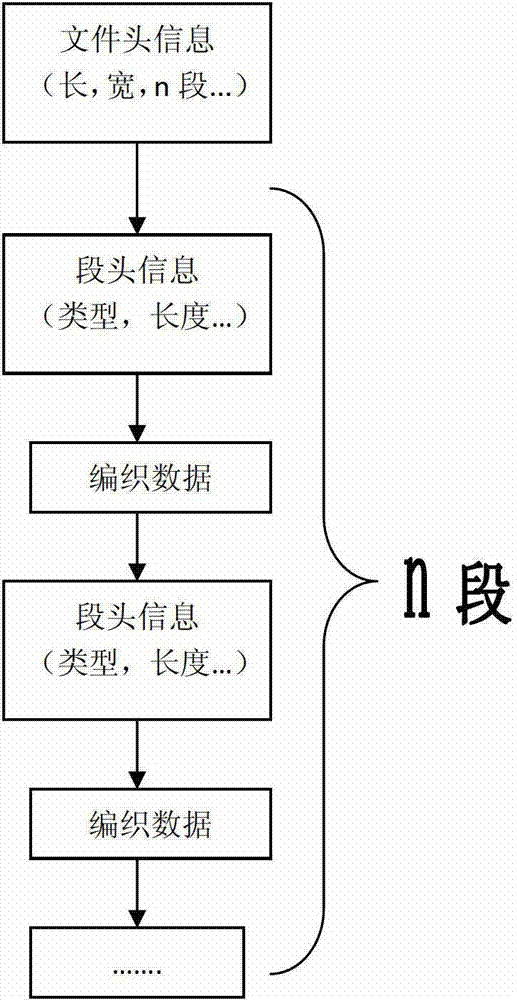

[0093] The system and method of the present invention will be further described below with reference to the accompanying drawings.

[0094] The plate making system of the present invention can be constructed based on an embedded system, etc., by configuring corresponding input and display accessories and corresponding program codes. It can also be built on a common PC by configuring corresponding software. The mouse, keyboard and its interface driver equipped for the PC constitute the input unit of the plate-making system, and the monitor, graphics card and its driver constitute the display unit of the plate-making system. The hard disk and memory form the storage unit of the plate-making system, and the CPU combines the system operation instructions to form the calculation unit.

[0095] The electronic control system can be constructed based on an embedded system by configuring corresponding interfaces, various execution components, and corresponding program codes. Its hardw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com