Electric connector and manufacturing method thereof

A technology for electronic connectors and connecting devices, which is applied in the direction of contact manufacturing, connection, and contact box/base manufacturing, etc., which can solve problems such as damage, small space, and easy breakage of free ends, and achieve low cost, high precision, and Ease of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

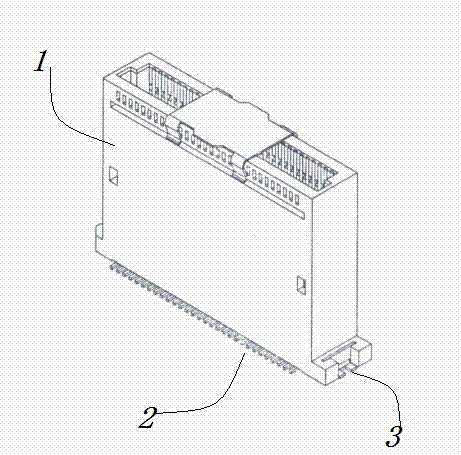

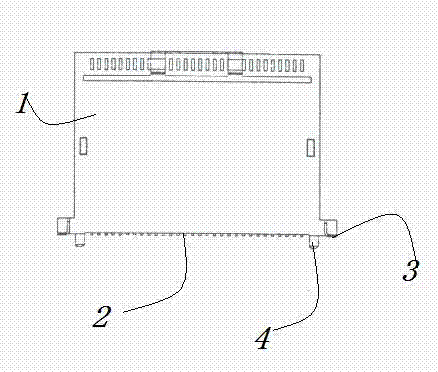

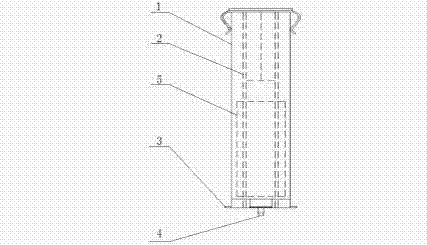

[0028] like figure 1 and figure 2 and image 3 As shown, the electronic connector of the present invention includes a shell 1 with upper and lower openings and two rows of PIN pins 2 arranged inside the shell 1 on the front and rear sides. Greater than 15mm, preferably greater than 22mm, this length can ensure that the relative electronic components have a sufficient distance when splicing PCB boards, and avoid mutual interference between PIN pins 2. The casing 1 is integrally molded by plastic injection molding, which has many advantages such as low cost, high precision, and convenience for large-scale production. One side of the PIN needle 2 is flush with the upper end of the shell 1, and a part of one side protrudes from the lower end of the shell 1, and the protruding part is bent outward. The two PIN needles 2 connected on each side are separated by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com