Underwater plug-pull connector and preparation method thereof

A technology for plugging and unplugging connectors, which is applied in the direction of connection, components of connecting devices, assembly/disassembly of contacts, etc., can solve problems such as unreliable sealing of underwater plug-in connectors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

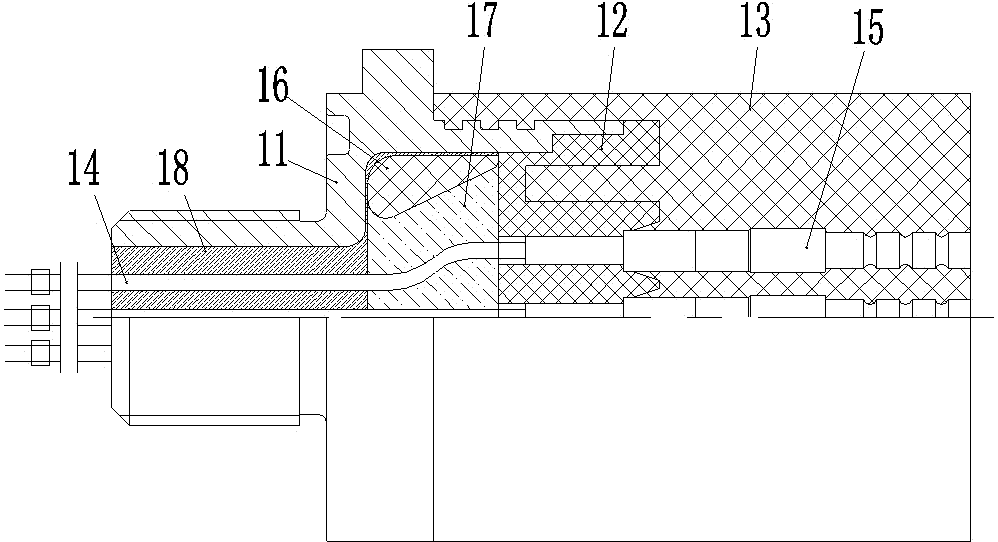

[0023] Embodiment 1 of the underwater plug connector of the present invention, such as figure 1 As shown, the connector takes the front end as the plug-in end, and includes a housing 11, an insulator 12, a vulcanized body 13, and a contact piece 15 connected with a wire 14. In this embodiment, the housing 11 is in the shape of a cylinder with two ends open. , the front end of the inner hole forms a stepped hole with a large front and a small rear, and a positioning step surface facing forward is formed between the large and small diameter sections of the stepped hole. The outer contour of the insulator 12 is a stepped shaft shape with a large front and a small rear, which includes The large-diameter section located at the front end and the small-diameter section located at the rear end form a mating stepped surface facing backwards between the large-diameter section of the insulator 12 and the small-diameter section. Complementary, its front end is also provided with a valgus ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com