Control method for preheating and roasting processes during production of traveling grate machine

A technology of belt roasting machine and control method, applied in the direction of measuring heat, thermometer with physical/chemical change, measuring device, etc., can solve the problem of lack of quantitative control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. Requirements: Corresponding to the specific belt roaster, each bellows of the burner section and the two bellows behind the burner section are equipped with thermocouples; the installation requirement is that 5 thermocouples are evenly distributed in the width direction of each bellows and they are as close as possible to the grate of the trolley bar for a more accurate exhaust gas temperature.

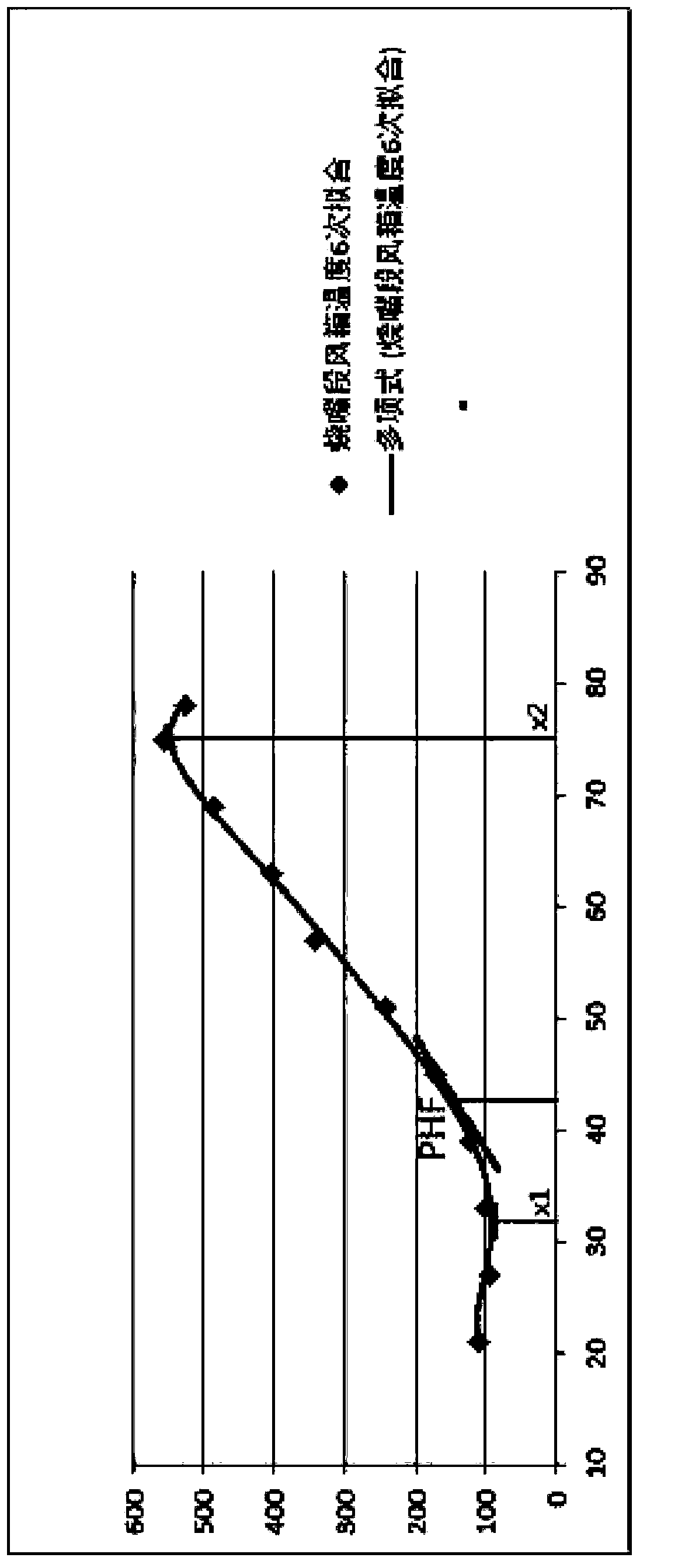

[0039] 1. Curve Fitting of Exhaust Gas Temperature

[0040] Analyze the detected exhaust gas temperature of the wind box, and average the five temperature detection values of each wind box to obtain the exhaust gas temperature of the wind box (the data form used for curve analysis is shown in the following table).

[0041] Table 1 Actual temperature data used for curve analysis

[0042] distance (m)

X1

X2

X3

X4

X5

X6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com