A kind of continuous mercerizing equipment

A technology of mercerizing and equipment, applied in the mercerizing of yarn/thread/filament, continuous processing of textile materials, singeing, etc., can solve the problems of water waste, negative effect of gloss, inability to coherence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

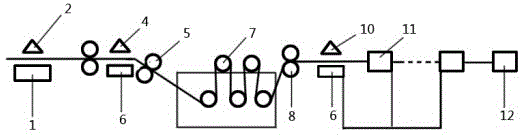

[0023] see figure 1 , a kind of continuous mercerizing equipment, comprises sequentially connected singeing device 1, and singeing device comprises smoking device 2; A pair of hot roller 3, can reduce fabric surface wrinkle by the hot extrusion of hot roller, improve mercerizing effect; Input guide roller; spraying device A; mercerizing groove; output guide roller 8; spraying device B; washing device; drying cylinder unit and winding unit; The roller group is equipped with a driving device for driving the rotation of the guide roller on the input heat roller and the output guide roller. A pressure sensor 7 is installed on any upper guide roller 9 in the mercerizing tank. When the pressure of the upper guide roller increases, the input and output guide rollers are accelerated. The speed of the roller can relieve the pressure caused by the shrinkage of the yarn and prevent it from being stuck. Spraying device A is used for spraying concentrated alkali solution, which plays the ...

Embodiment 2

[0025] A continuous mercerizing process using the mercerizing equipment, including the hairiness treatment of the fabric to be treated through a singeing device, and then being squeezed by a hot roller to reduce the surface wrinkles of the fabric, and the spraying device A pre-sprays concentrated lye, and then enters The guide rollers are introduced into the mercerizing tank for mercerizing treatment, and finally go through the output guide rollers, spray device B and washing box for washing and drying. Spraying equipment A and B adopt intermittent spraying, spraying once every 2-5s, which can not only save energy but also achieve the effect of pre-soaking and washing; the number of spraying holes is 180. The spraying temperature of spraying equipment B is 45-60°C, which is slightly lower than the conventional spraying temperature, which can effectively reduce the degree of hydrolysis of dyes on the cloth surface, reduce the negative impact of the alkali removal process on the ...

Embodiment 3

[0027] A continuous mercerizing process using the mercerizing equipment. The 60s purple jacquard is subjected to hairiness treatment through a singeing device, and then squeezed by a hot roller to reduce wrinkles on the surface of the fabric. The rollers are introduced into the mercerizing tank for mercerizing treatment, and finally go through the output guide roller, spray device B and washing box for washing and drying. Sprinklers A and B adopt intermittent spraying, spraying once every 2-5s, which can not only save energy but also achieve the effect of pre-soaking and washing; the number of spray holes is 270. The spraying temperature of spraying equipment B is 45-60°C, which is slightly lower than the conventional spraying temperature, which can effectively reduce the degree of hydrolysis of dyes on the cloth surface, reduce the negative impact of the alkali removal process on the color of the cloth surface, and at the same time improve the color fastness of the fabric. Am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com