High-pressure cylinder of ultra-supercritical steam turbine set

A steam turbine unit, ultra-supercritical technology, applied in the direction of mechanical equipment, engine components, machines/engines, etc., can solve problems such as steam pressure, limited temperature, increased manufacturing cost of high-pressure cylinders, impact on steam turbine unit efficiency, etc., and achieve maintenance costs low cost, high reliability, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

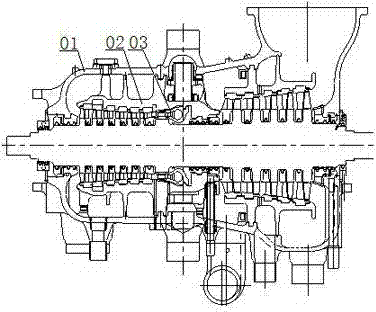

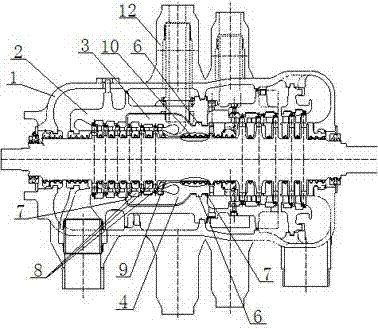

[0024] see image 3 and Figure 4 : A high-pressure cylinder of an ultra-supercritical steam turbine unit. The steam parameters of the ultra-supercritical steam turbine unit are about 31MPa / 600°C / 620°C / 620°C. The high-pressure cylinder is mainly composed of an outer cylinder 1, an inner cylinder 2 and a steam inlet chamber.

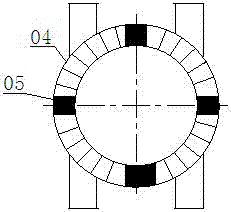

[0025] Among them, the outer cylinder 1 is mainly composed of a semi-annular upper half body and a lower half body that cooperate with the sky and the earth. The upper half body and the lower half body of the outer cylinder 1 are combined together by connecting bolts, and the connecting bolts are connected on the flange of the middle surface. Contact stress is generated, and then the outer cylinder 1 is sealed; the inner cylinder 2 is also mainly composed of a semi-annular upper half and a lower half that cooperate with the sky and the earth. The upper half and lower half of the inner cylinder 2 are combined by connecting bolts. The connecting bolts gene...

Embodiment 2

[0028] The other structures of this embodiment are the same as those of Embodiment 1, except that: the steam parameters of the ultra-supercritical steam turbine unit are about 35MPa / 700°C / 600°C / 600°C; The steam chamber is made of expensive nickel-based alloy; the inner cylinder 2 is equipped with seven-stage partitions, and the inner cylinder 2 and the outer cylinder 1 are respectively made of high-temperature-resistant alloy material CB2 cast steel. In this case, the pressure of the steam introduced into the steam inlet chamber through the steam inlet pipe 12 is about 35MPa, and the temperature is 700°C. When the steam enters the steam chamber to perform work, the steam pressure drops by about 14 MPa and the temperature drops by about 100°C. , at this time, the pressure of the steam entering the inner cylinder 2 through the steam inlet chamber to do work is about 21 MPa, and the temperature is about 600°C. After calculation and analysis, the steam inlet chamber has good air ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com