Design method of direct type LED (light-emitting diode) backlight module

A technology of a backlight module and a design method, which is applied in the design field of direct-lit LED backlight modules, can solve problems such as crosstalk of a shutter-type 3D liquid crystal display screen, and achieve the effect of solving the problem of crosstalk and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The direct type LED backlight module design method of the present invention comprises:

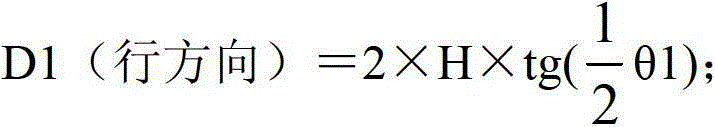

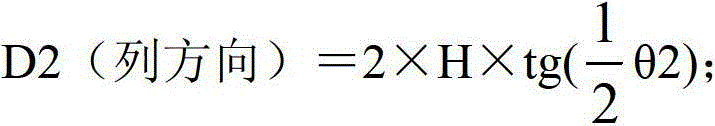

[0022] a. According to the LED light mixing distance H set in the liquid crystal module, the row-direction luminous angle θ1 of the LED, and the column-direction luminous angle θ2 of the LED, determine the maximum spacing of the LEDs in the row direction and the column direction:

[0023]

[0024]

[0025] b. Based on the maximum spacing in the row direction and column direction obtained in step a, based on the maximum spacing D1 and D2 in the row direction and column direction obtained in step a, according to the row length N1 and column length N2 of the liquid crystal module, it is obtained to satisfy The minimum number of LEDs required for the basic optical requirements of the LCD module

[0026] Calculate the actual number of LEDs required according to the actual brightness requirements and energy efficiency requirements of the LCD module Where L is the brightness of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com