Normally closed quickly installed damping clamp

A damping wire, normally closed technology, which is applied in the field of normally closed quick installation damping wire clips, can solve the problems of high physical exertion of construction personnel, easy falling of accessories, and low installation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

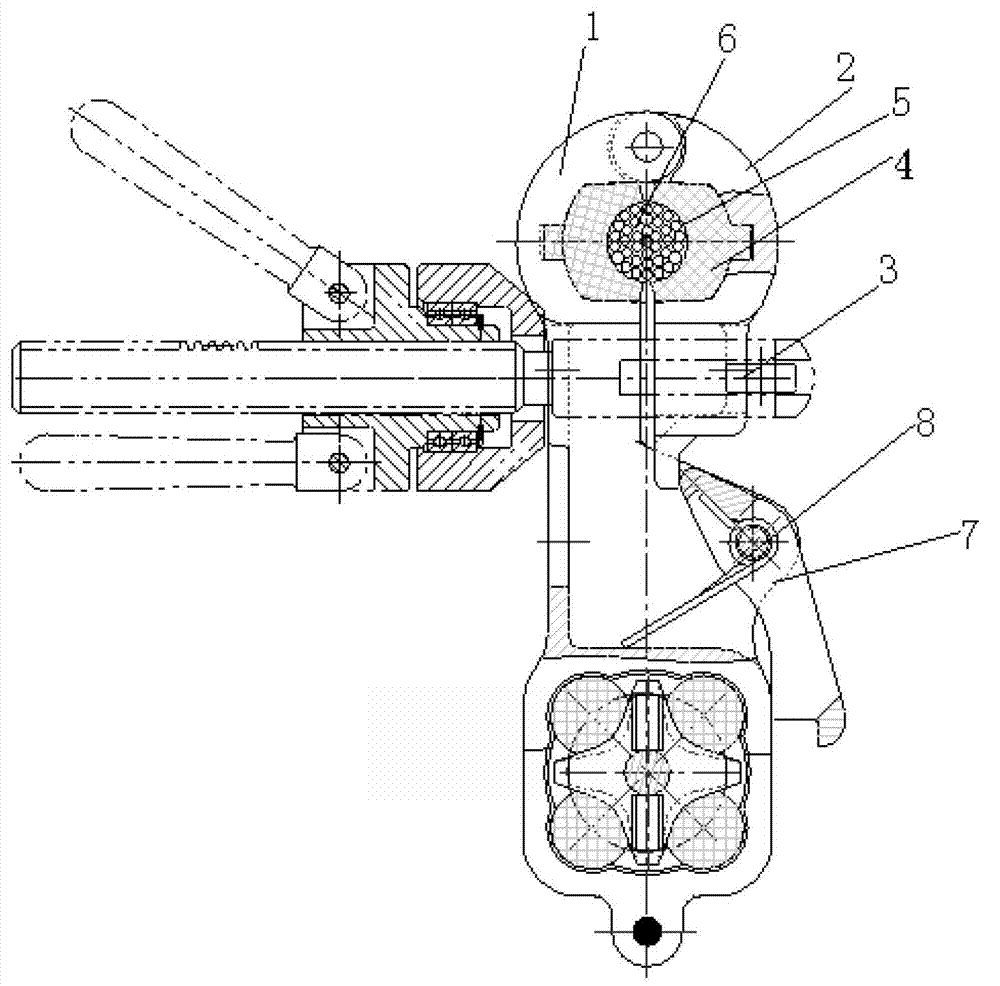

[0019] Referring to the accompanying drawings, the normally closed fast installation damping clamp includes a clamp main body 1, one end of the clamp main body 1 is hinged with a gland 2, and a locking pin 3 is connected between the clamp main body 1 and the other end of the gland 2, The gland 2 and the clamp main body 1 are respectively equipped with matching wired clamping tiles 4, and the two wired clamping tiles 4 are respectively provided with corresponding semicircular grooves 5, two semicircular grooves 5 There is a wire 6 in the cooperating clamp, and a pawl 7 is hinged on the main body of the wire clamp 1 through a torsion spring 8. The front end of the pawl 7 is buckled on the inner side of the rear end of the gland 2, the rear end of the pawl 7 is tilted, and the pawl 7 automatically When resetting, it is 45° with the clamp main body 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com