Power supply processing device and discharging control method thereof

A technology of power processing and discharge control, which is applied in the direction of electric light sources, lighting devices, lamp circuit layout, etc., and can solve the problems of unfinished design of power processing devices, poor design, and poor quality products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

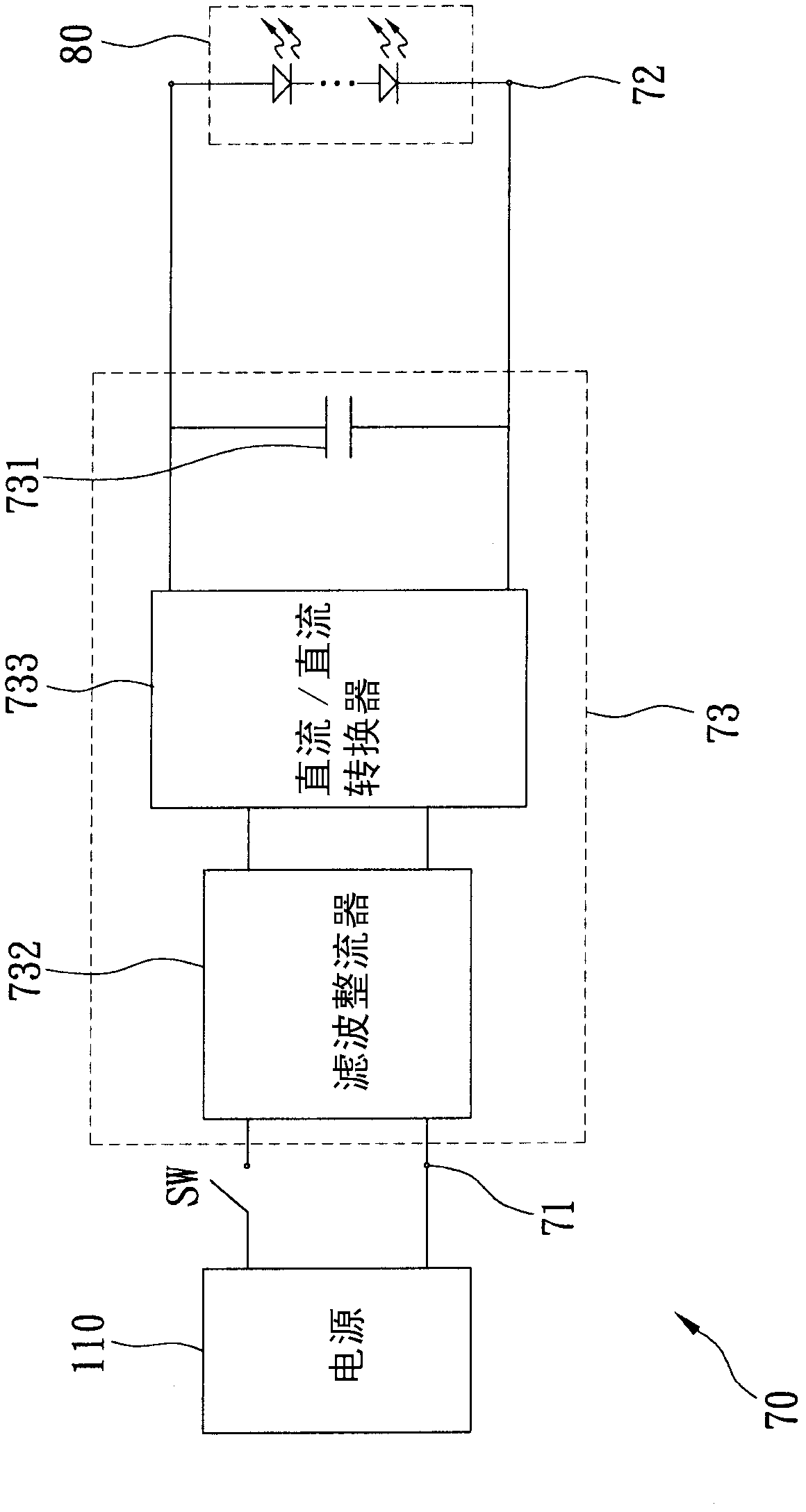

[0025] see image 3 , the first preferred embodiment of the present invention includes a power processing device 10 and a plurality of light-emitting diodes (Light-emitting diode, LED) 20, the power processing device 10 is used to receive and convert the electric energy of a power source 100 for the light emitting Diode 20, in this embodiment, the power supply 100 is the AC power supply provided by the power company, but it is not limited thereto, and it can also be converted to a power generation energy storage system (such as wind power generation, solar power generation, Geothermal power generation, etc.) generated DC power or AC power. The power processing device 10 includes an input port 11, an output port 12, a power conversion module 13 and a discharge module 14, wherein:

[0026] The input port 11 is used to electrically connect with the power source 100 .

[0027] The output port 12 is used to electrically connect with the LED 20 .

[0028] The power conversion mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com