Automatic adjusting method for LED (Light Emitting Diode) luminous flux

A technology of automatic adjustment and luminous flux, applied in the direction of light source, electric light source, lighting device, etc., can solve the problems of super bright light distribution and substandard light distribution, and achieve the effect of increasing luminous flux, convenient and timely control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

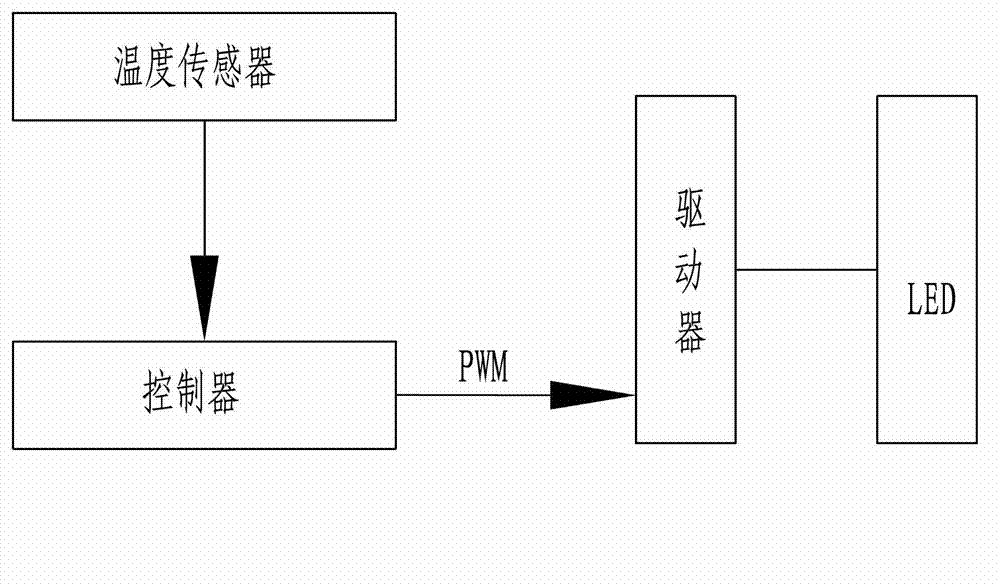

[0024] The LED luminous flux automatic adjustment method of the present invention,

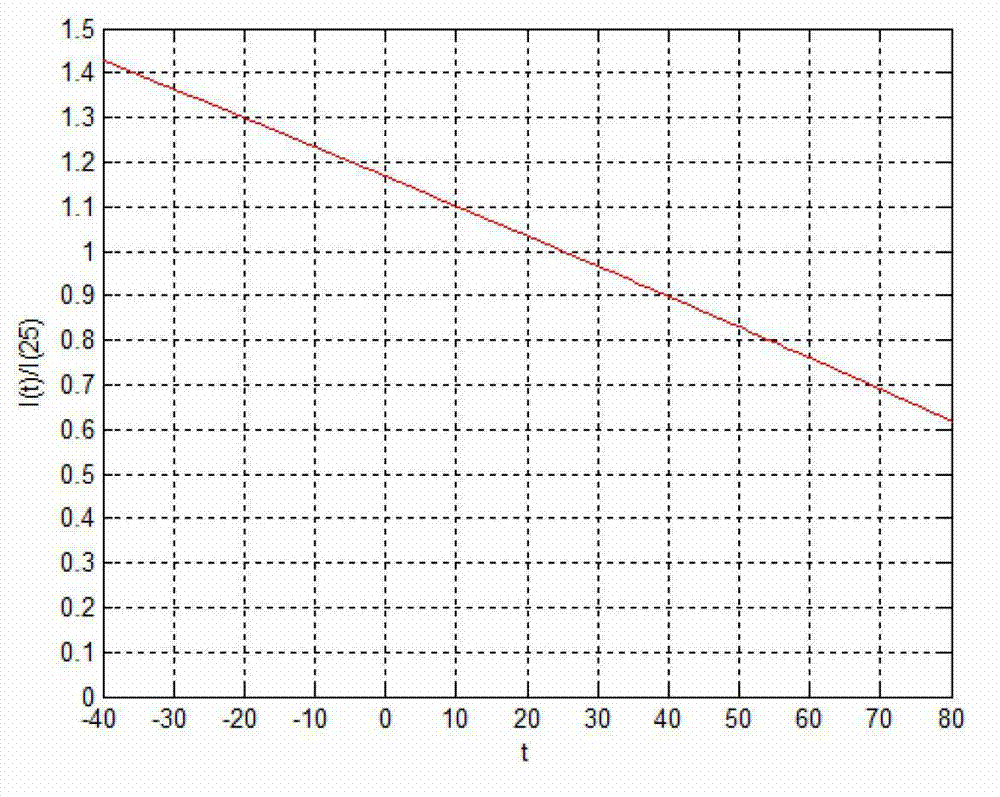

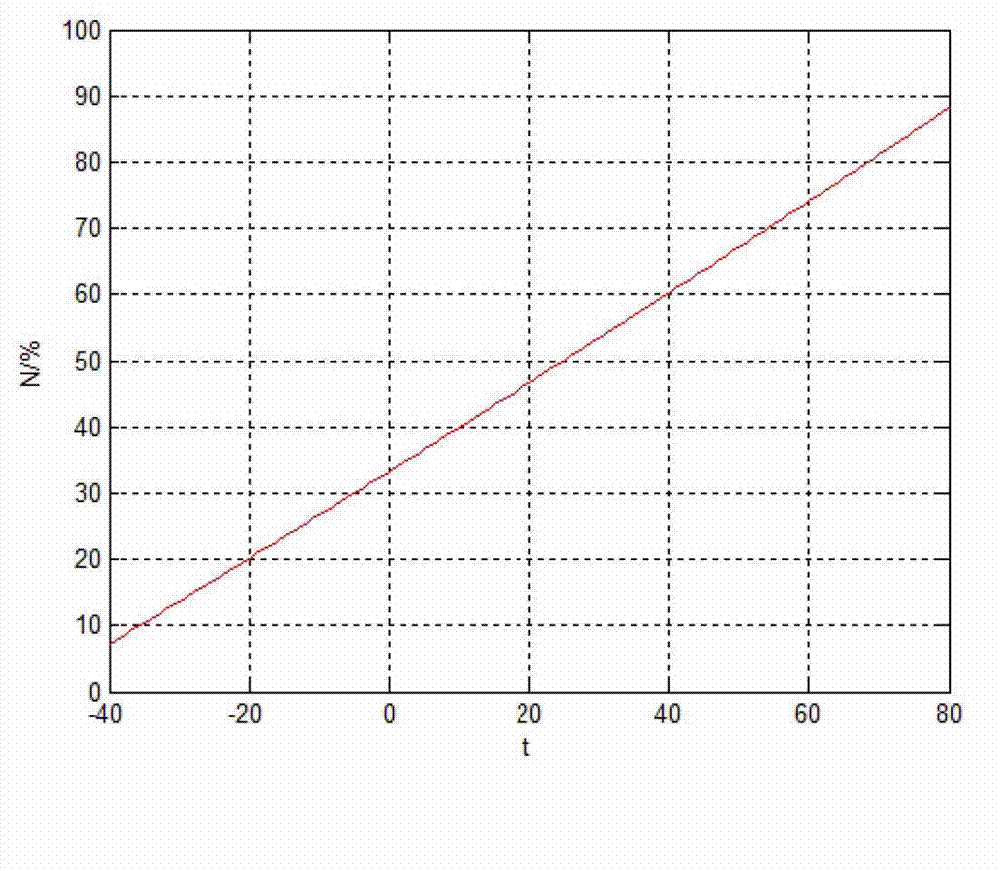

[0025] (1) Establish the linear relationship between the luminous flux output by the LED and the LED operating temperature and the linear relationship between the duty cycle of the PWM signal and the luminous flux output by the LED, and store them in the controller. The linear relationship between the luminous flux output by the LED of the present invention and the LED operating temperature Relational expression:

[0026]

[0027] Where: t is the LED operating temperature, t is between -40°C and 80°C,

[0028] I (t) is the output luminous flux at the LED working temperature t,

[0029] I(0°C) is the luminous flux output when the LED operating temperature t is 0°C,

[0030] I (25℃) is the output LED luminous flux when the LED operating temperature t is 25°C,

[0031] I(-40°C) is the output luminous flux when the LED working temperature t is at -40°C,

[0032] I(80°C) is the output lumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com