Electrophotographic-photosensitive element and method for manufacturing the element, and electrophotographic device using the same

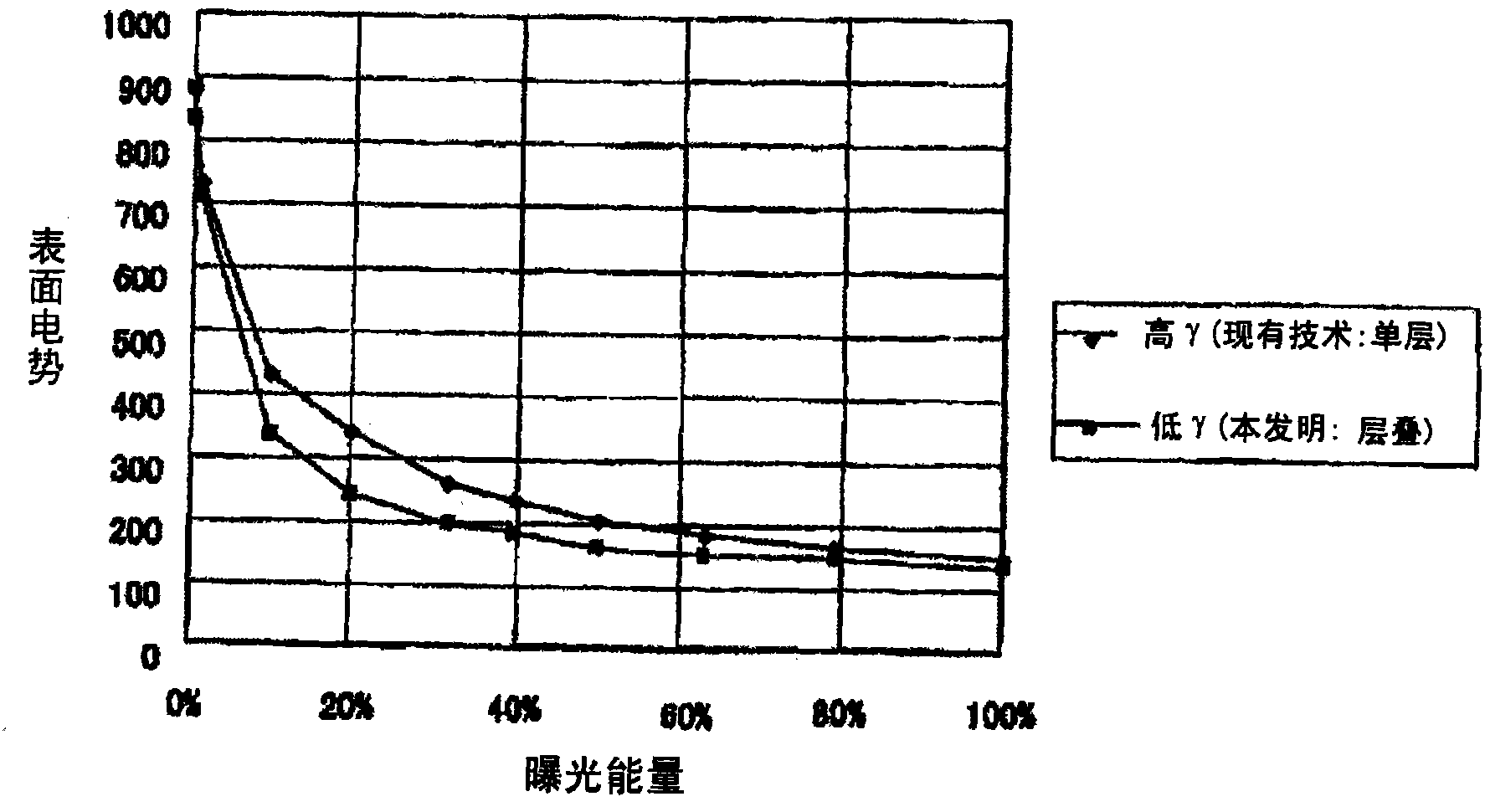

A technology of electrophotography and photoreceptor, which is applied in the fields of optics, electrical recording, instruments, etc., and can solve the problems that cannot be produced, and high-resolution performance cannot be utilized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

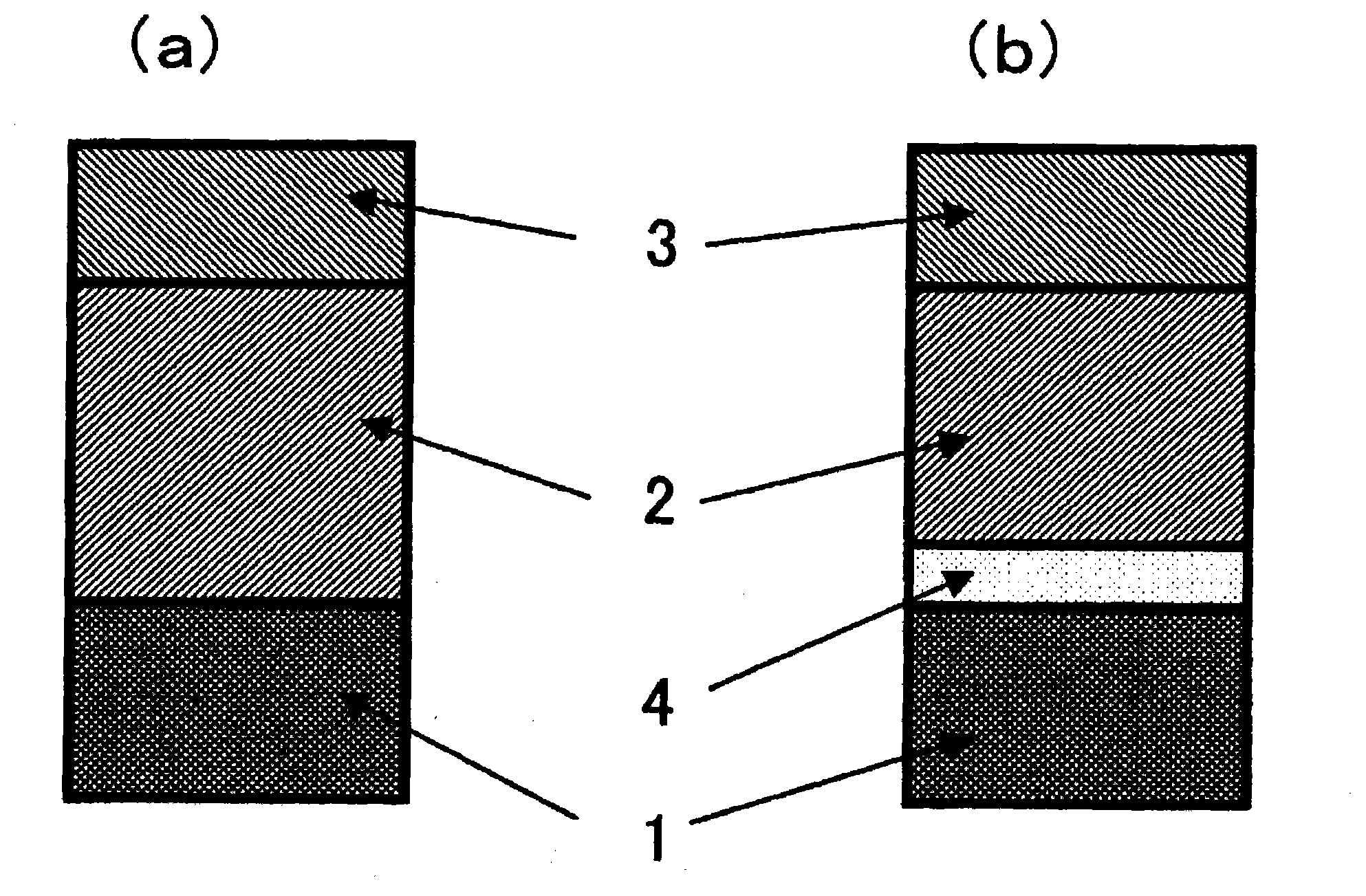

[0097] Embodiments of the present invention are described below

[0098] (Example of Manufacture of Electrophotographic Photoreceptor)

[0099] [conductive substrate]

[0100] Using an aluminum tube, which is cut and machined into a shape with a diameter of 30 mm x 244.5 mm, the surface roughness (R 最大 ) is 0.2, and the wall thickness is 0.75 mm.

[0101] [Preparation of Charge Transport Layer Coating Liquid]

[0102] A styrene-based compound (HTM-A) described below was used as a hole transport material (hereinafter abbreviated as "HTM"), and polystyrene "PS-680" (manufactured by PS Japan Corporation) was used as a binder. A mixture resin, each of which was contained in an amount of 100 parts by weight; these components were dissolved in methylene chloride as a solvent to prepare a charge transport layer coating liquid. Polystyrene usually contains mineral oil, but this can be detrimental to the sensitivity characteristics when used in the binder resin of OPC. On the othe...

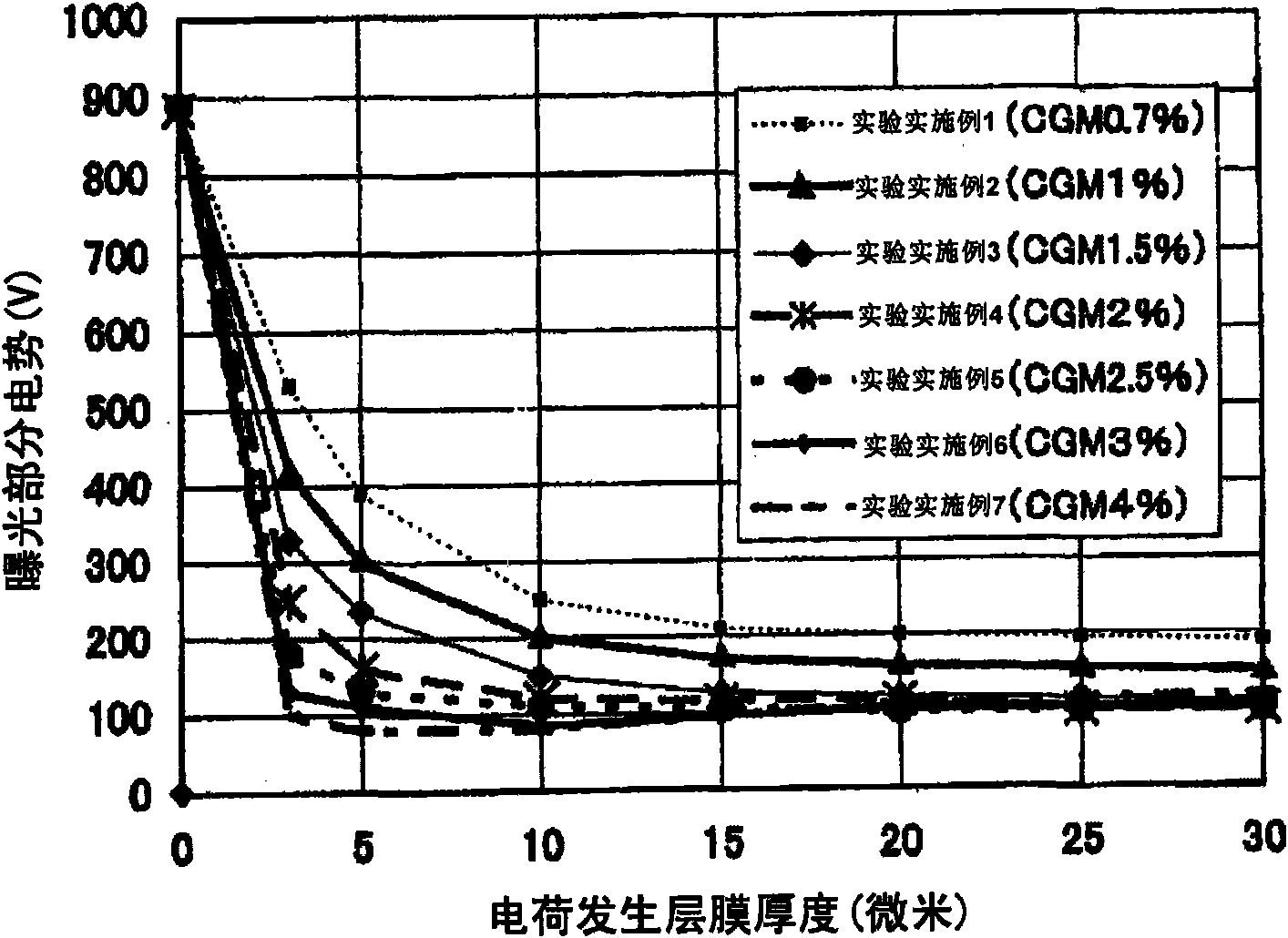

experiment Embodiment 1-7

[0113] As shown in Table 1 below, various stacked positively charged OPCs were manufactured, and the charge-generating material addition amount in the charge-generating layer of Experimental Examples 1-7 was varied in the range of 0.7-4% by weight. In Experimental Examples 2-5 of the present invention, the charge generating material was added in an amount of 1 wt%, 1.5 wt%, 2 wt% and 2.5 wt% in the positively charged laminated OPC. In the experimental example, the film thickness of the charge transport layer was set to 3 microns, 5 microns, 10 microns, 15 microns, 20 microns, 25 microns and 30 microns, and the total film thickness including the charge transport layer was fixed at 30 micron photoreceptor.

[0114] These photoreceptors were mounted in a Brother Industries "HL5240" model 1200 DPI high-resolution printer using a non-magnetic one-component contact development detergent-free process using suspension-polymerized toner, 30 ppm (A4 equivalent), Measure the potential o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com