Automatic on-line verification system for electronic thermometers

An electronic thermometer, automatic technology, applied in thermometers, thermometer testing/calibration, sensors, etc., can solve the problems of low degree of automation, low efficiency of electronic thermometers, fixed verification time, etc., to achieve the effect of increasing the degree of automation and improving the efficiency of verification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

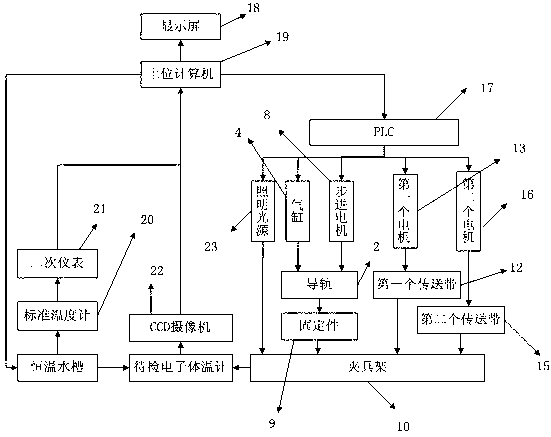

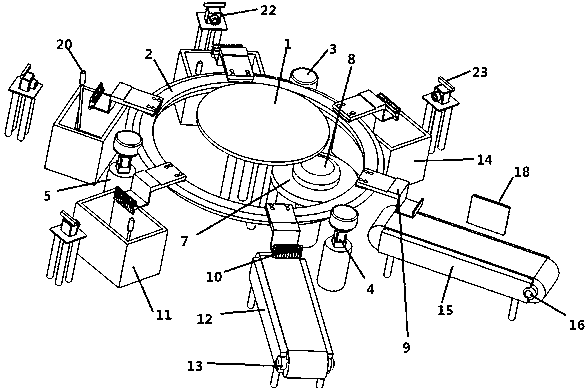

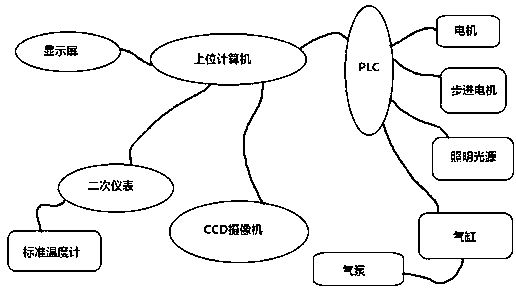

[0024] (1) The verification personnel install the electronic thermometer on the fixture frame 10 of the electronic thermometer, and put the fixture frame 10 on the first conveyor belt 12;

[0025] (2) The upper computer 19 sends instructions to the PLC programmable controller 17, controls the cylinder 4 to lower the guide rail 2, and controls the first motor 13 to drive the conveyor belt to rotate to transport the fixture frame 10 to the end close to the first constant temperature bath 11, Control the stepping motor 8 to rotate the guide rail 2 so that the fixing part 9 is located under the fixture frame 10, and then the guide rail 2 is raised so that the fixing part 9 lifts the fixture frame 10;

[0026] (3) Control the stepper motor 8 to rotate the guide rail 2 so that the first fixture frame is facing the first constant temperature bath, control the cylinder 4 to make the guide rail 2 descend, and the sensor part of the electronic thermometer is immersed in the medium of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com