Additive bin dust collection device and using method thereof

A technology of dust removal device and admixture, which is applied in the direction of removing smoke and dust, separation methods, chemical instruments and methods, etc., can solve the problems of dust spillage, pollution of the environment, and long draft ducts, so as to avoid waste, solve environmental pollution problems, and save energy. The effect of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

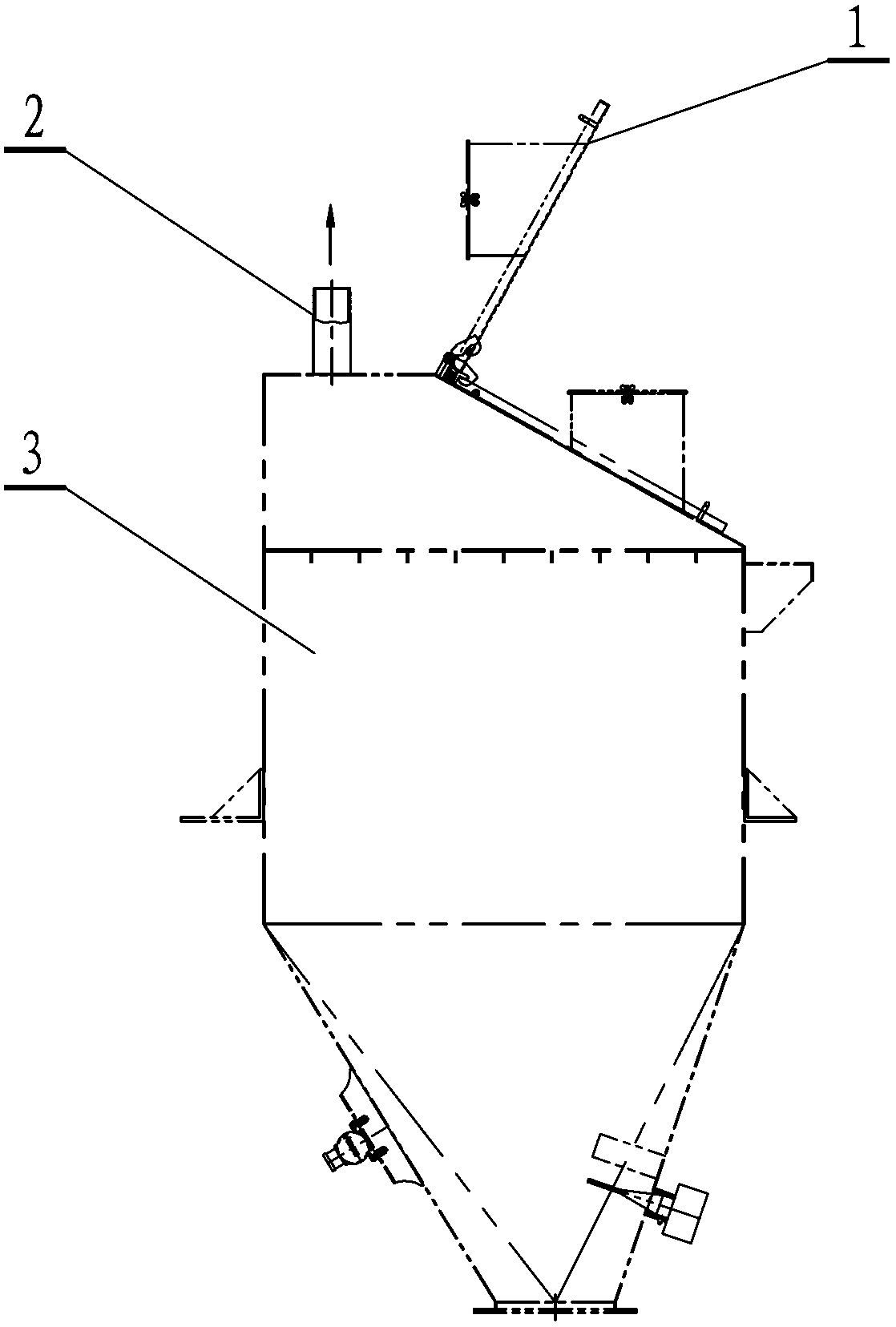

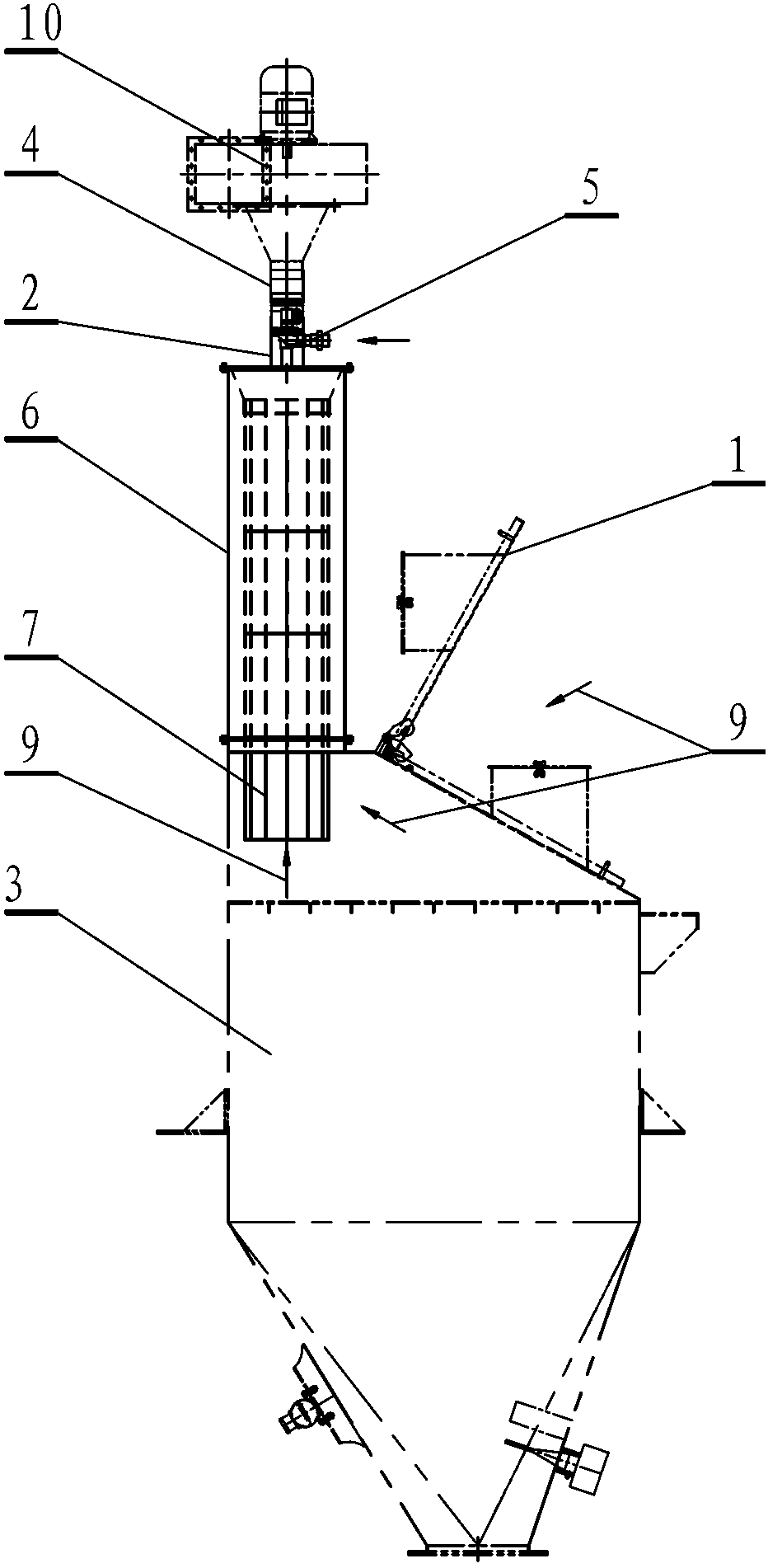

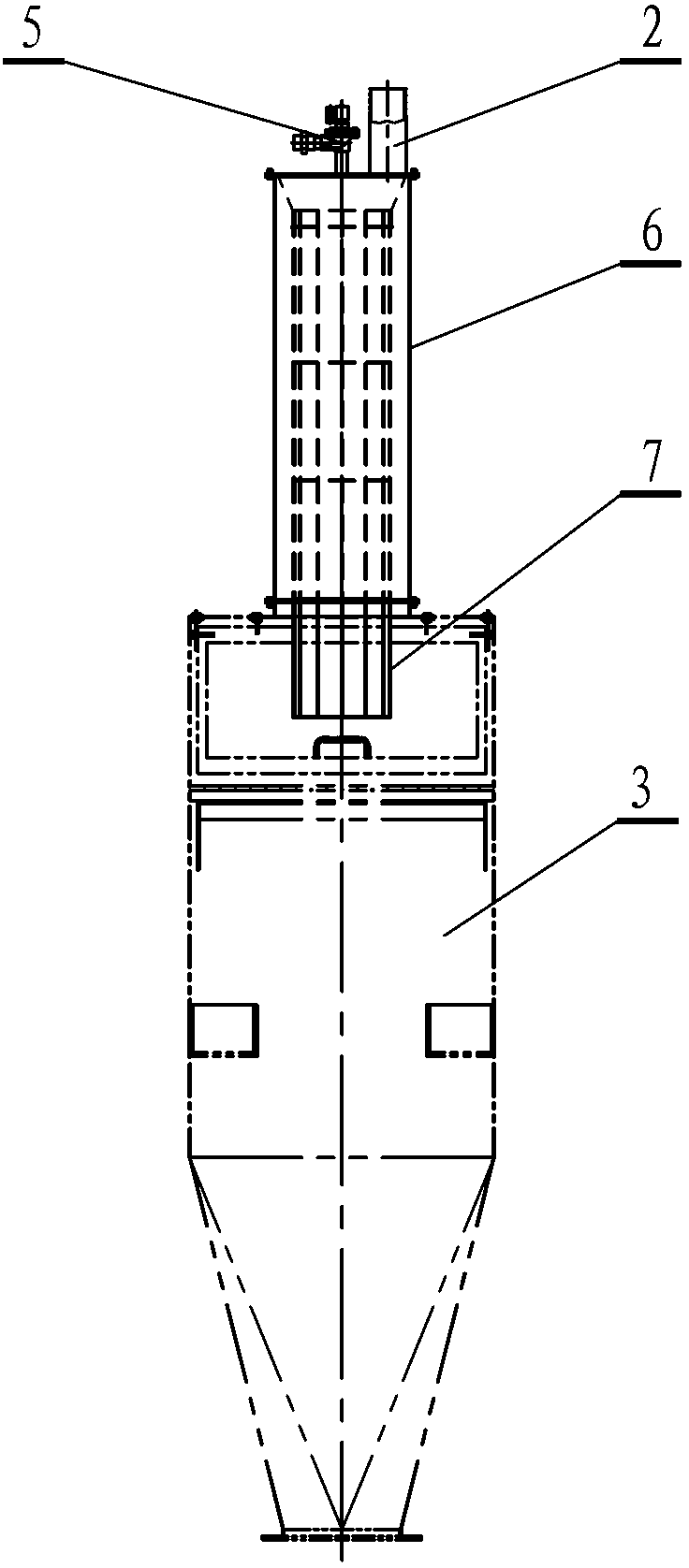

[0031] See figure 2 , image 3 , the lower end of the outer cylinder 6 is connected to the admixture bin 3 through a flange, and the upper end is connected to the blowback pulse valve 5 and the induced air pipe 2 through a flange cover 12, the induced air pipe 2 is connected to the induced fan 10 through a flexible joint 4, and the flange cover 12 hangs a filter bag 7, the skeleton 8 of the filter bag 7 is installed inside the outer cylinder 6, and the blowback pulse valve 5 is connected to the air source of the air compressor.

[0032] The structure of filter bag 7 is shown in Figure 4 , on the flange cover 12, the back blow joint 11 and the induced air pipe 2 are respectively welded, the other side of the flange cover 12 is welded with the big head of the tapered pipe 13, the small head of the tapered pipe 13 is welded with the skeleton 8, and the skeleton 8 A filter bag 15 is sheathed on the outside, and the filter bag 15 is fixed on the frame 8 through a clamp 14 . Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com