Driving device in micro-flow pipeline

An internal drive and pipeline technology, applied in the field of fluid mechanics, can solve problems such as weakening the accuracy of test results and sample contamination, and achieve the effects of increasing surface area, reducing pollution, and improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

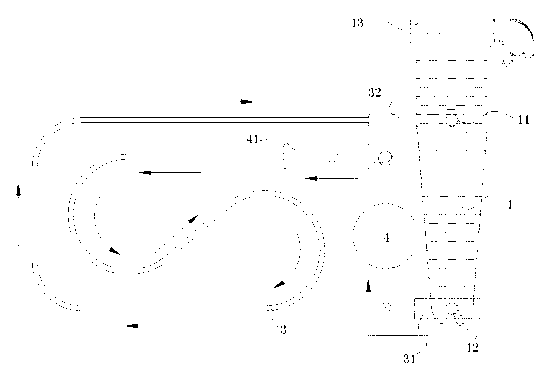

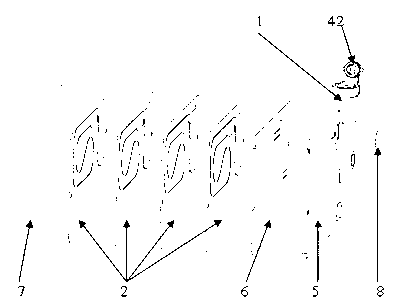

[0029] Further, the fluid chamber 1 also includes a loading port 13 for loading fluid into the fluid chamber 4 , and a sealing cover 42 is provided on the loading port.

[0030] Example 2

Embodiment 2

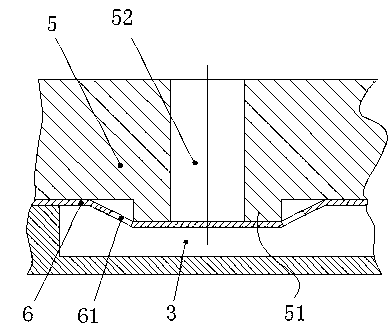

[0032] like image 3 As shown, further, the liquid inlet 31 is provided with a first one-way valve, and the fluid flows from the fluid chamber 1 to the vibration chamber 4 through the first one-way valve. The structure of the first one-way valve is: The first boss 51 on the top and the first overflow groove 61 provided on the vibrating membrane 6, the first boss 51 protrudes toward the direction of the channel membrane, the first boss 51 is provided with a small hole 52, and the small hole 52 passes through the substrate 5 The channel provided on the top is connected to the fluid chamber 1, and the fluid enters the one-way valve through the channel. The first overflow groove 61 on the vibrating membrane 6 is set outside the first boss 51, specifically around the small hole 52. , the first overflow groove 61 is used to release the fluid flowing out from the small hole 52 into the microfluidic pipeline 3 provided on the channel membrane 2, so the first overflow groove 61 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com