Angular fixer

A fixer and angle-shaped technology, applied in the field of angle-shaped fixers, can solve problems such as safety hazards of simple hoisting tools, strong dependence on large hoisting equipment, inconvenient production, etc., and achieve the effect of saving tedious work, reducing potential safety hazards, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A specific embodiment is enumerated below in conjunction with the accompanying drawings to further illustrate the present invention.

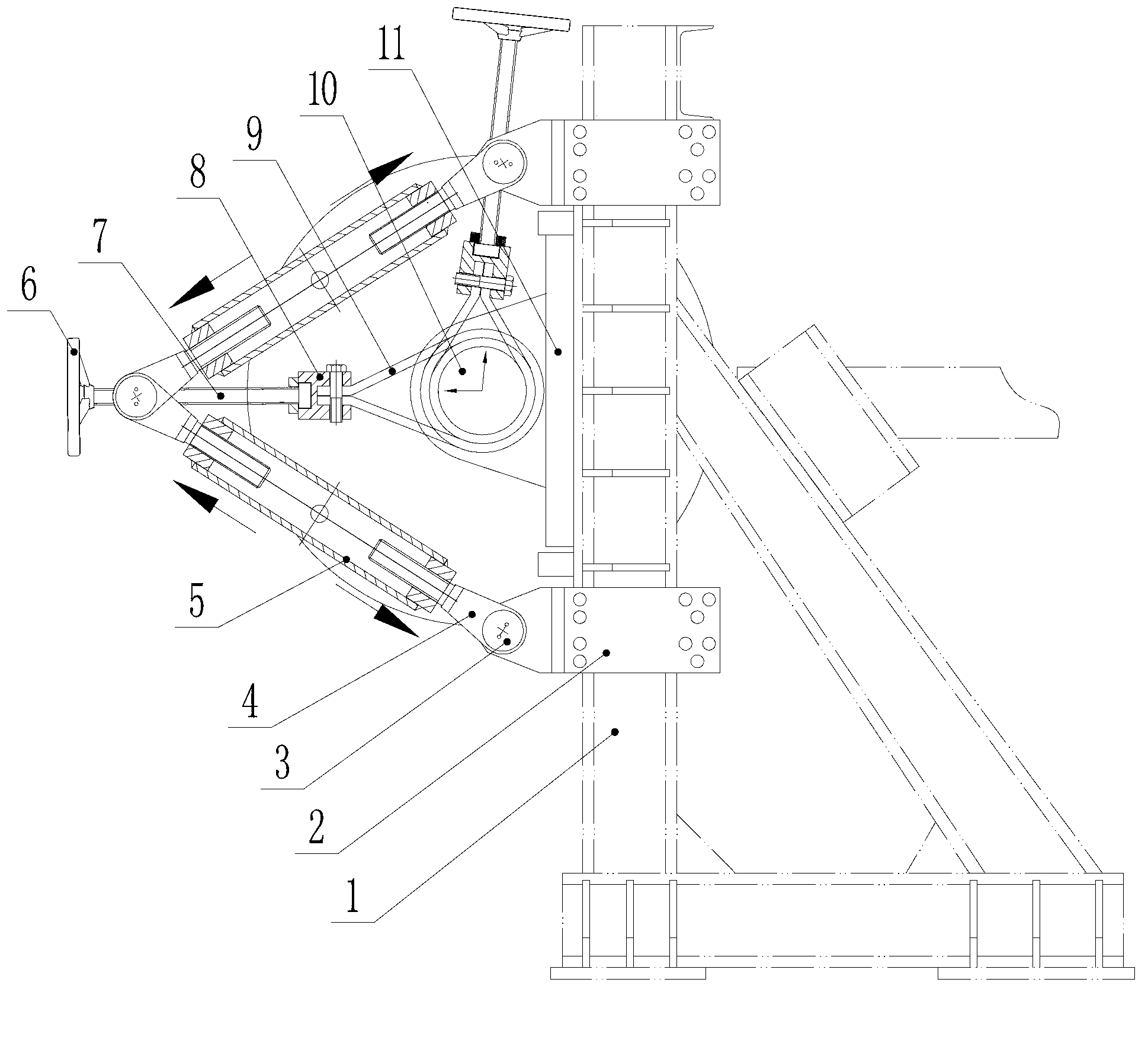

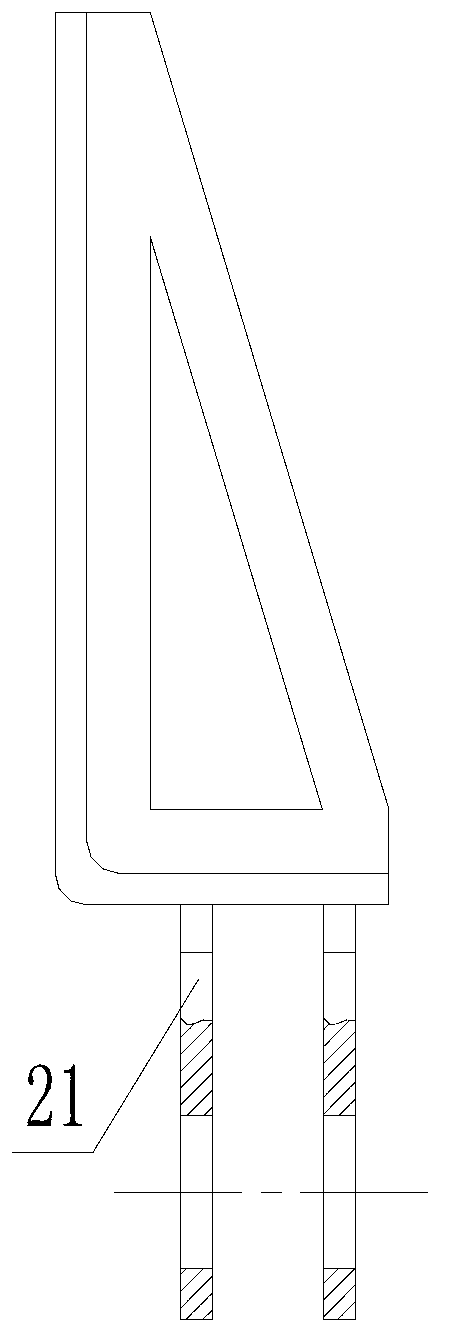

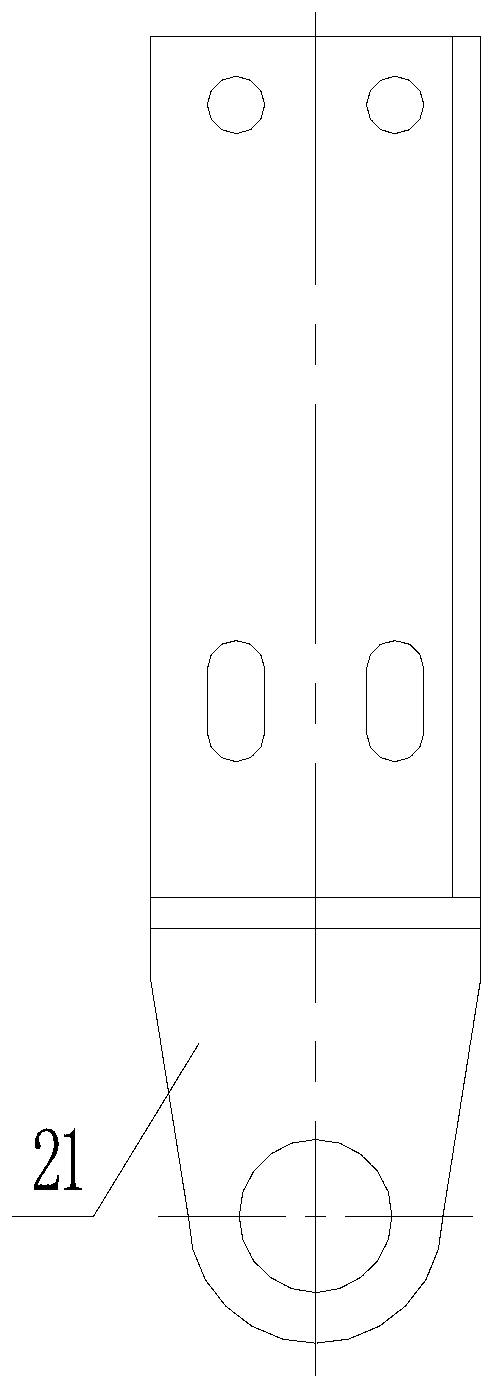

[0027] Such as figure 1 As shown, the present embodiment is an angle fixer, including two fixing frames 2 and an adjusting arm 5; both fixing frames are affixed to the equipment used to affix the bearing seat 11, and the two fixing frames 2 are located at Both sides of the bearing seat 11; between the adjustment arm 5 and the fixed frame 2, and between the two adjustment arms 5 are hinged through a connecting shaft 3; a screw hole is provided in the radial direction of the connecting shaft 3, and the screw hole is matched with an adjusting screw 7. One end of the adjusting lead screw 7 is connected to a winding piece, and the winding piece is set on the piece to be fixed.

[0028] Such as figure 1 As shown, in this embodiment, the equipment for fixing the bearing is the frame 1, the wrapping part is a flexible wrapping part, the sling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com