Double-salient liquid cooling eddy current retarder with front-loading gearbox

A technology of eddy current retarder and retarder, which is applied in the direction of asynchronous induction clutch/brake, motor, electric vehicle, etc. It can solve the problems of affecting the service life of the gearbox, reducing the service life of the clutch disc, and the impact of the gearbox gear. , to achieve the effects of compact structure, increased service life, and large equivalent torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

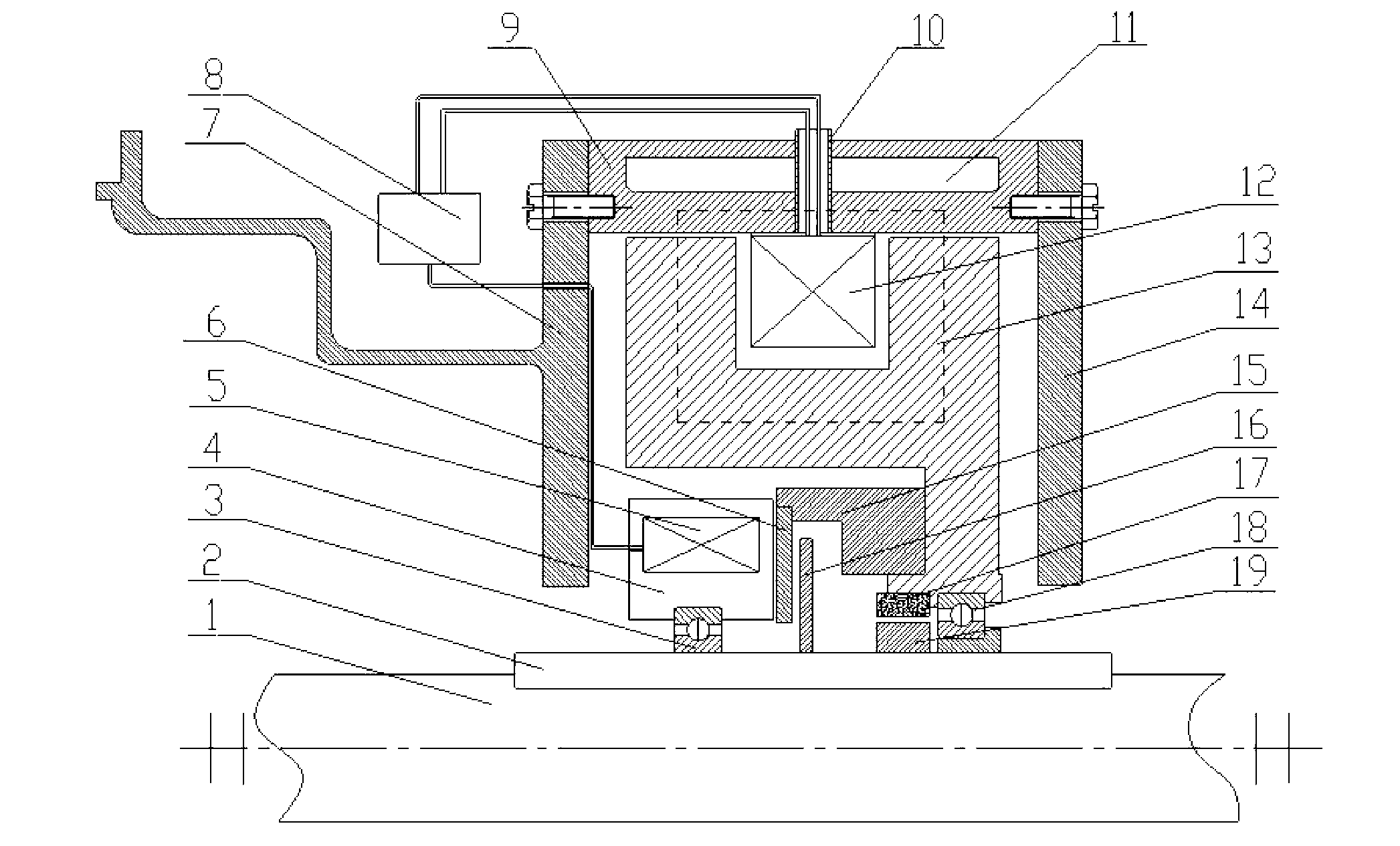

[0020] Such as figure 1 As shown, the clutch yoke 4 is connected to the key 2 and the transmission shaft 1 through the yoke support bearing 3, the clutch coil 5 is connected to the control module 8, and the driven disc friction plate group 6 in the clutch disc 15 is connected to the retarder rotor through screws. 13, and the pressure plate 16 is connected with the transmission shaft 1 through the key 2. The retarder coil 12 is concentratedly wound to form an independent coil, which is fixed on the inner wall of the retarder stator 9 and installed between two salient poles of the retarder rotor 13 . The wires of the retarder coil 12 are led out through the wire sleeve 10 passing through the retarder stator 9 and connected to the control module 8 , and the control module 8 controls the clutch coil 5 and the retarder coil 12 . The retarder rotor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com