Rear floor body structure and rear floor assembly structure with rear engine

A technology of assembly structure and rear floor, which is applied in the field of vehicle rear floor structure and engine rear floor structure, can solve the problems that cannot meet the structural strength requirements of the engine rear vehicle model, and achieve the effect of good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

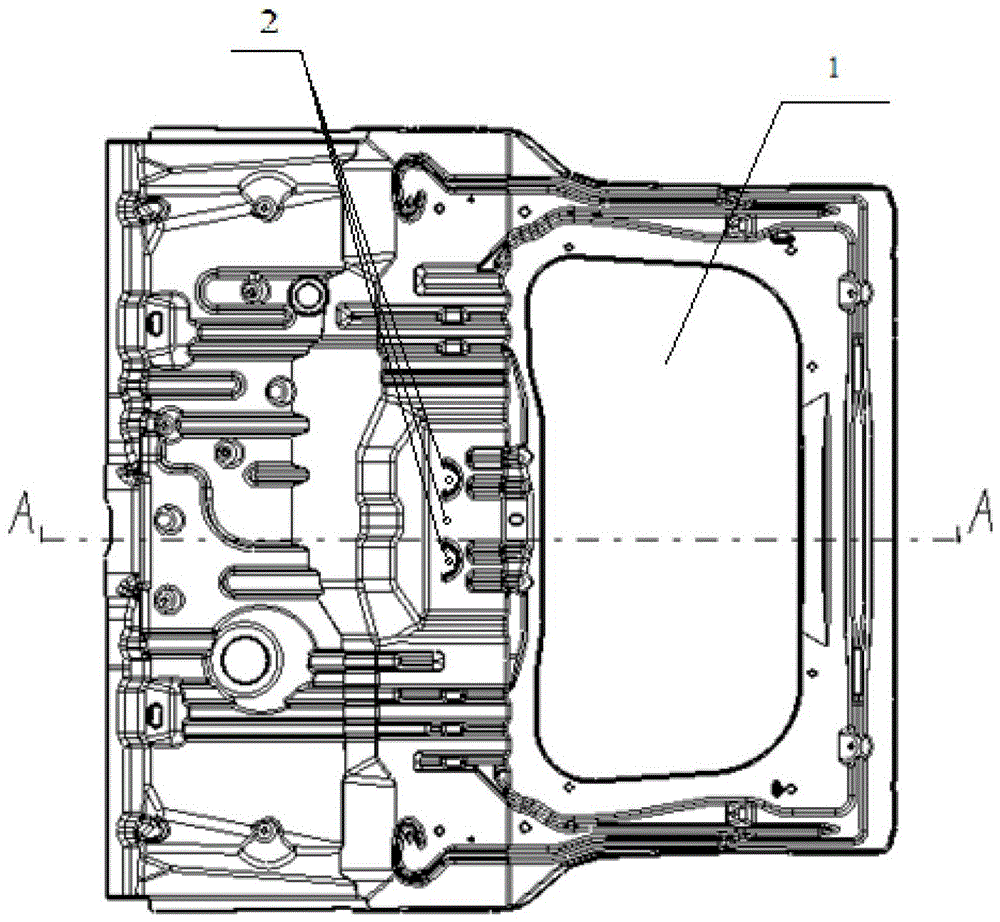

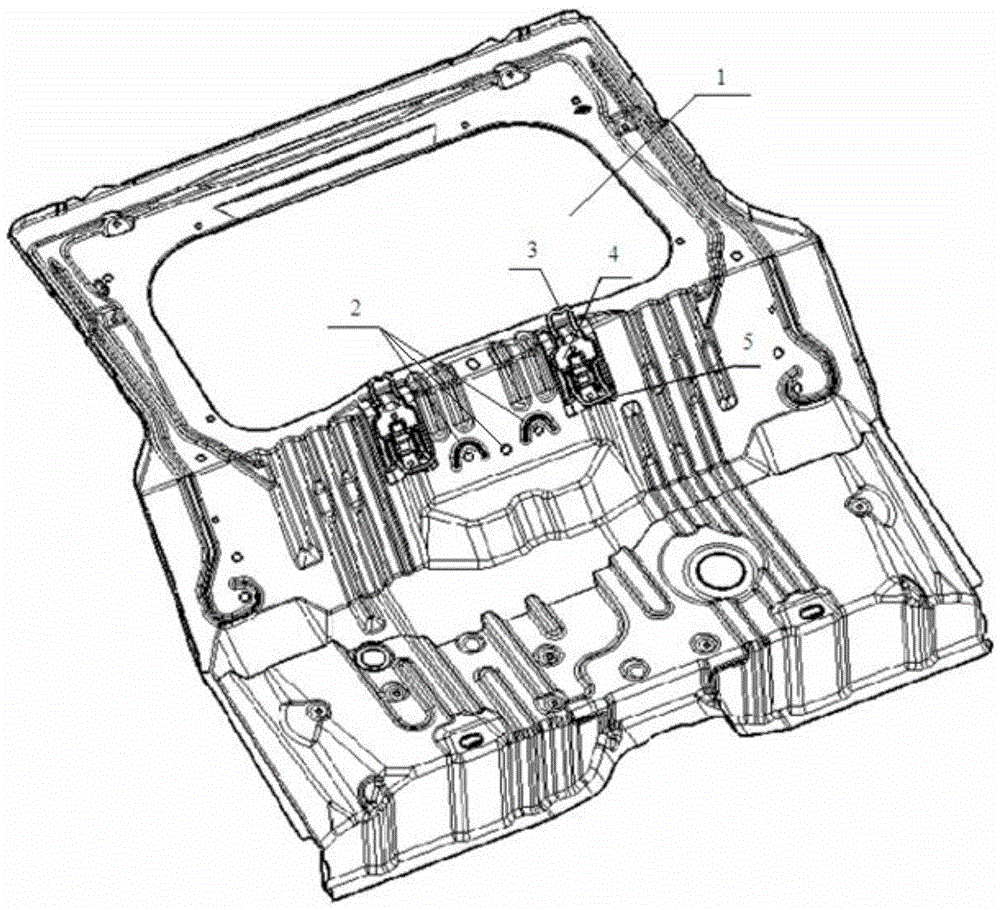

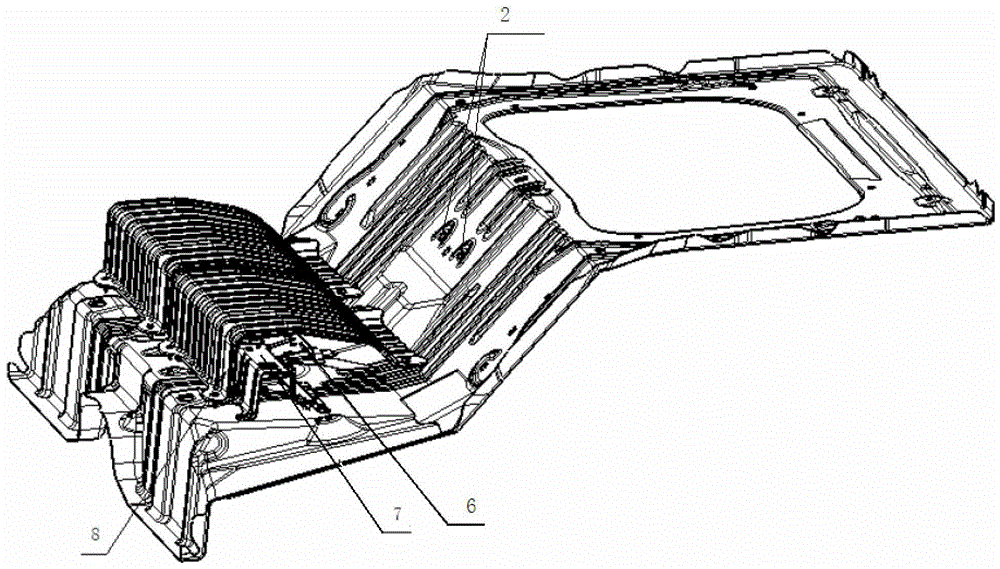

[0019] Such as figure 1 As shown, a rear floor body structure includes a first main board, a third main board and a second main board connecting the first main board and the third main board, the first main board, the second main board and the third main board The plates are distributed in steps, and the first main body plate is provided with a special-shaped hole 1 for arranging the engine.

[0020] The structure of the rear floor body is stepped, which fully considers the space problem of compact small cars and meets the requirements of related layout. And because the structure of the rear floor body structure is changed, the wrinkled rear floor structure is adopted. Compared with the conventional in-line rear floor body structure, the strength and rigidity of the entire rear floor body are improved, and the installation of the rear floor body structure is avoided. Deformation occurs during the process or use, which greatly improves the structural strength of the rear floor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com