Installation method of glass window

An installation method and glass window technology, applied in the installation of window glass, screen with clear view, transportation and packaging, etc., can solve the problems of easily scratched surface, blurred, long cycle, etc., and achieve good clarity of light transmission , easy to obtain materials, easy to produce effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] see Figure 1-Figure 4 , a method for installing a glass window provided in the embodiment of the present application, comprising the following steps:

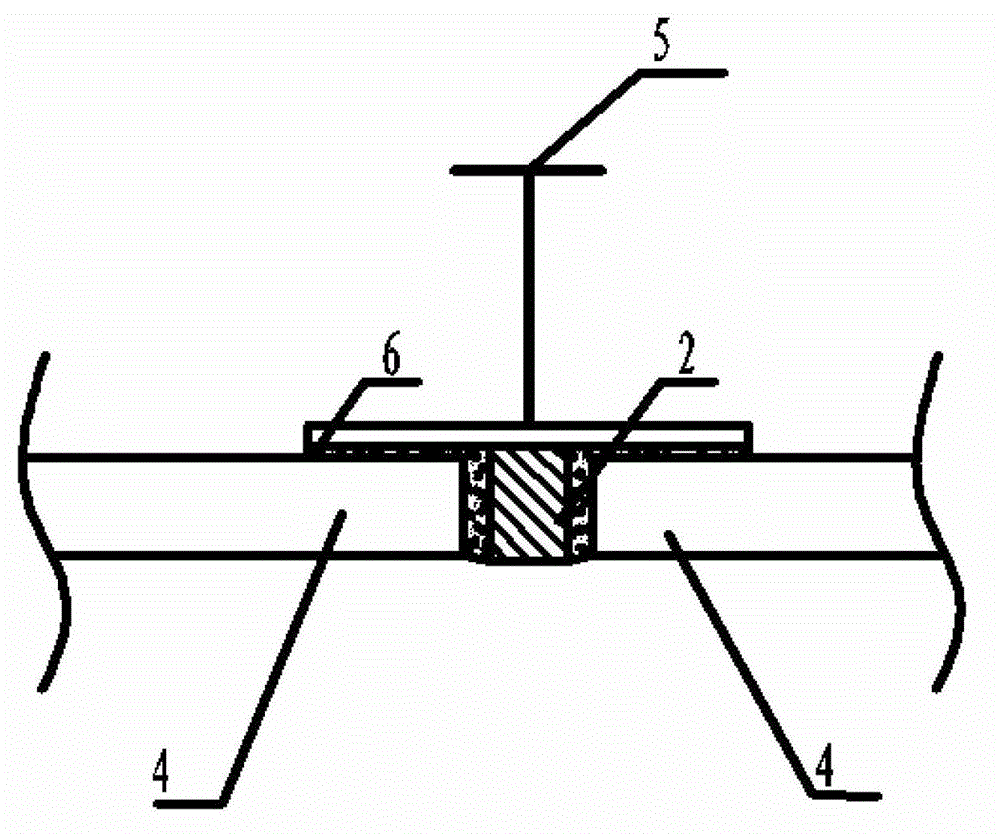

[0021] Step 10: Before placing the glass 4 on the window seat, paste tape on both sides of the glass 4 except for the edge, so as to prevent the glass 4 from being polluted by the glue 6 applied when installing the glass 4 .

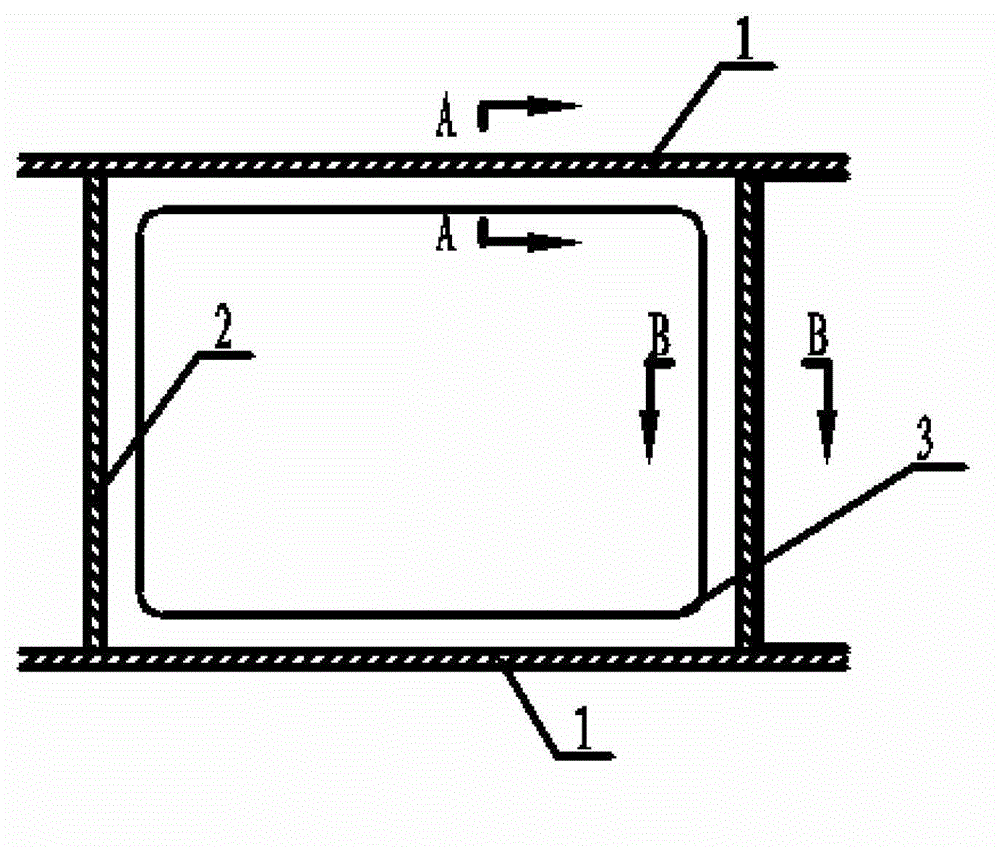

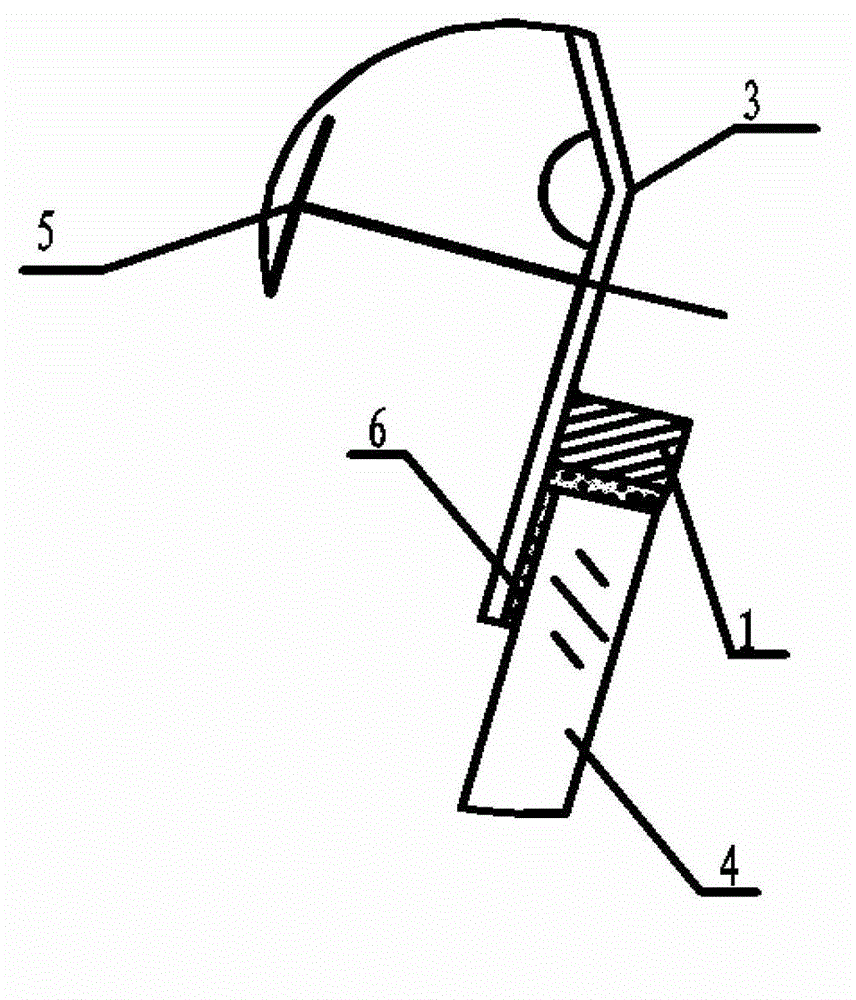

[0022] Step 20: Install the window seat on the ship's side shell 3. Specifically: see figure 1 , two parallel horizontal materials 1 (using aluminum flat steel) are fixed (such as welding) on the ship's outboard plate 3 . Fix (as by welding) several vertical materials 2 (using aluminum flat steel) between two parallel horizontal materials 1 to form a square window seat on the ship's side shell plate 3 . The number of vertical members 2 is determined according to the number of glass windows (if N glass windows need to be installed, then the number of vertical members 2 is N+1). Each square wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com