Snow removal shovel applicable to complex pavements

A snow shovel and snow shovel technology, applied in the field of snow shovel, can solve the problems of removal, damage to the snow shovel, and difficulty in snow accumulation, and achieve the effect of a reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

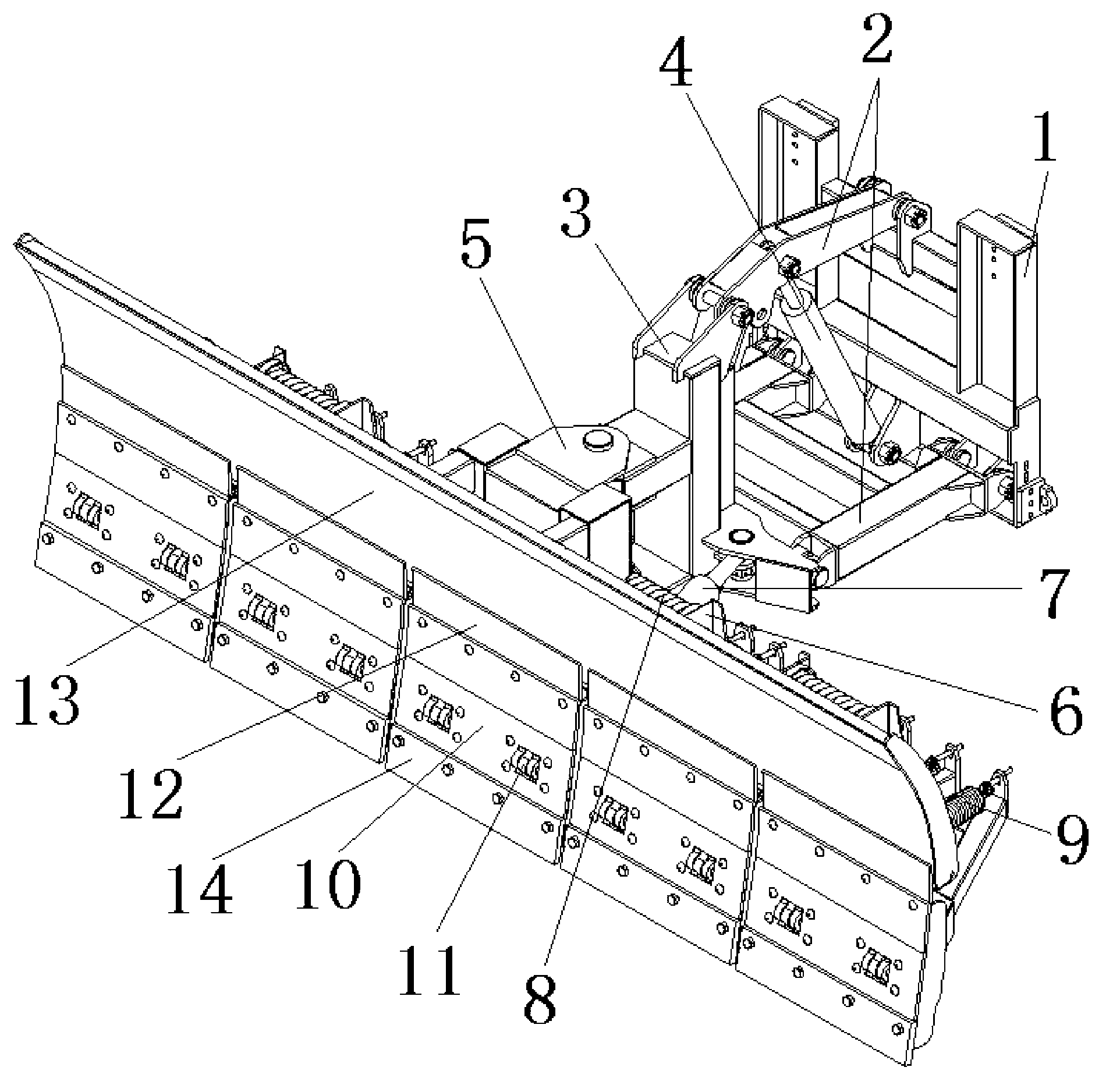

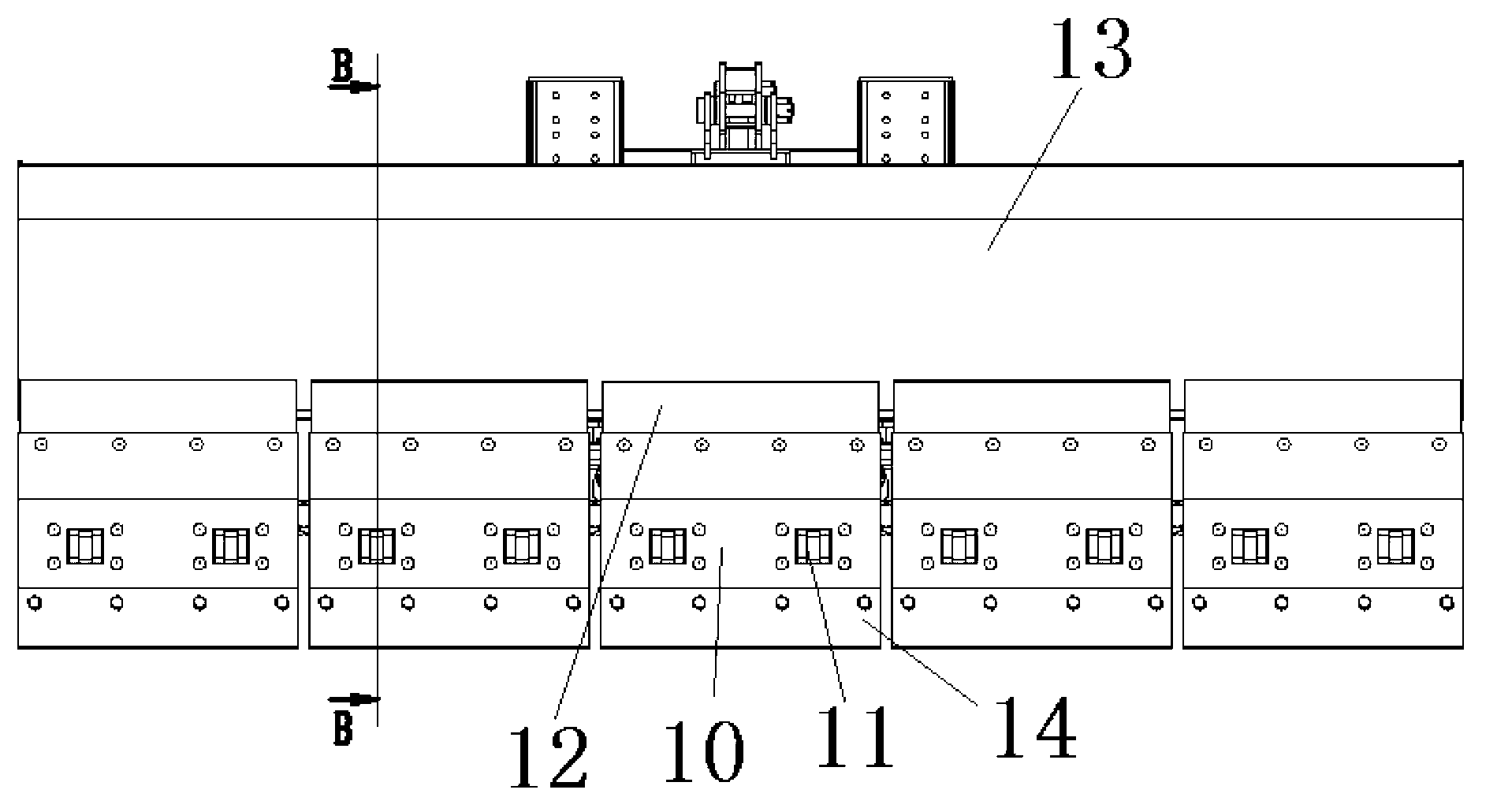

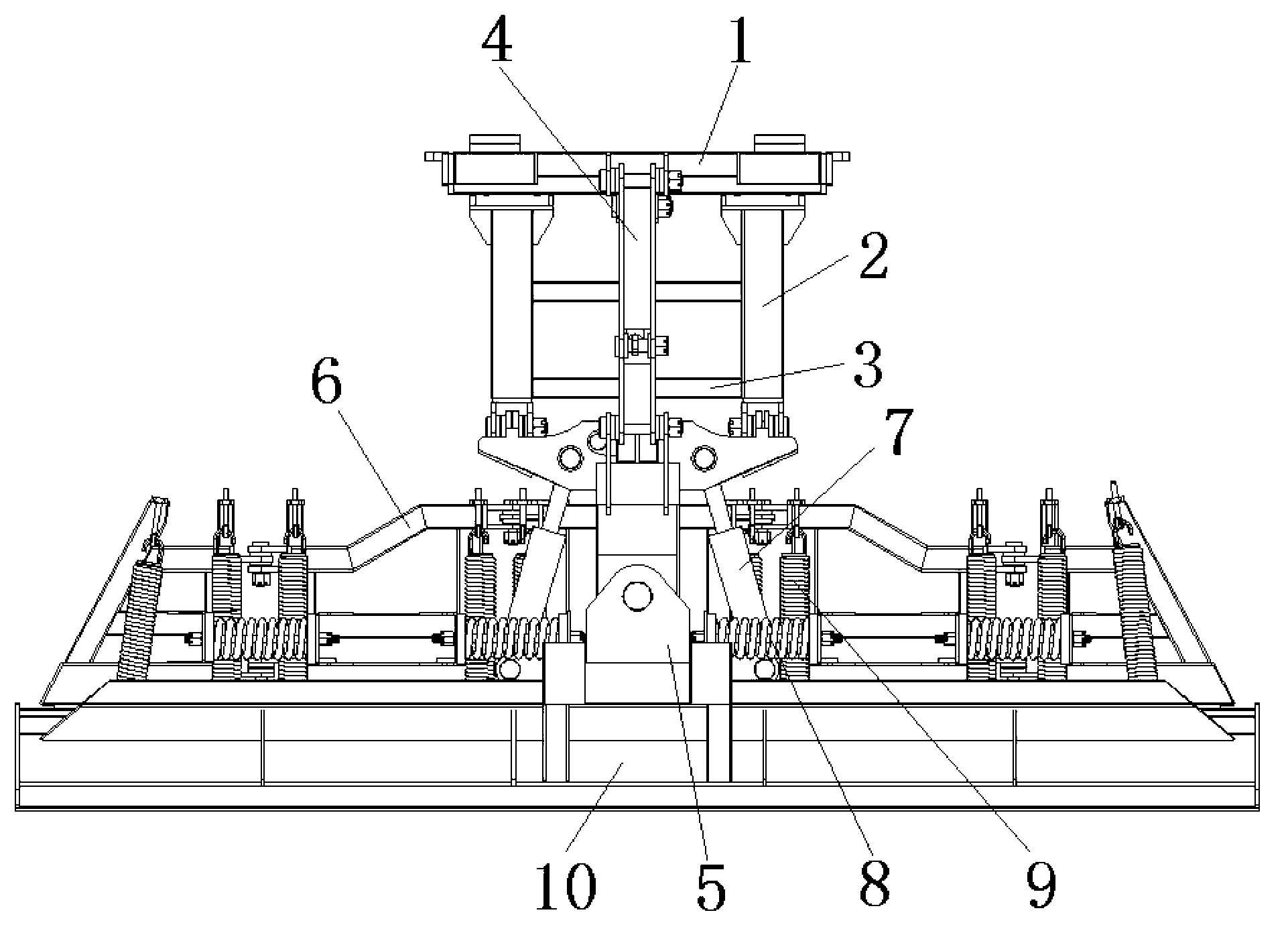

[0031] This embodiment provides a snow removal shovel suitable for complex road surfaces, characterized in that: the snow removal shovel suitable for complex road surfaces includes a fixed frame 1, a linkage mechanism 2, an undercarriage 3, and a hydraulic cylinder 4 for controlling lift-off , the main snow shovel frame 5, the side snow shovel frame 6, the hydraulic cylinder 7 that controls the rotation of the main snow shovel, the spring 8 that pushes the snow shovel to swing left and right, the spring 9 that pulls the snow shovel to swing back and forth, and the snow shovel 10, used for the front and rear of the snow shovel Swing hinged device 11, snow shield 12, snow shovel cross plate 13, snow shovel blade 14;

[0032] Among them: the fixed frame 1 is hinged with the landing gear 3 through the connecting rod mechanism 2 to form a parallelogram structure; one end of the hydraulic cylinder 4 controlling the lift is hinged with the bottom of the fixed frame 1, and the other en...

Embodiment 2

[0044] This embodiment is similar in structure to Embodiment 1, the difference is that the snow removal shovel suitable for complex road surfaces also includes an extended snow shovel frame 15, and the number of the extended snow shovel frames 15 is 2;

[0045] The extended snow shovel frame 15 is respectively installed on the two outer sides of the two side snow shovel frames 6 and arranged symmetrically;

[0046] A snow shovel 10 is hinged on each extended snow shovel frame 15, the snow shield 12 is installed on the top of the snow shovel 10, and the snow shovel blade 14 is installed on the bottom of the snow shovel 10;

[0047] The extended snow shovel frame 15 is hinged with the side bottom of the side snow shovel frame 6, and a spring 8 that pushes the snow shovel to swing left and right is installed between the upper parts of the two sides, and the two ends of the spring 9 that pulls the snow shovel to swing back and forth are installed on the extended snow shovel respect...

Embodiment 3

[0049] This embodiment is similar in structure to Embodiment 1, the difference is that the snow removal shovel suitable for complex road surfaces also includes an extended snow shovel frame 15, and the number of the extended snow shovel frames 15 is four;

[0050] Two extended snow shovel frames 15 form a group, and after the two are hinged, the expanded snow shovel frames 15 installed in combination are respectively installed on the two outer sides of the two side snow shovel frames 6, and arranged symmetrically;

[0051] A snow shovel 10 is hinged on each extended snow shovel frame 15, the snow shield 12 is installed on the top of the snow shovel 10, and the snow shovel blade 14 is installed on the bottom of the snow shovel 10;

[0052] The extended snow shovel frame 15 is hinged with the side bottom of the side snow shovel frame 6, and a spring 8 that pushes the snow shovel to swing left and right is installed between the upper parts of the two sides, and the two ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com