Acquisition and processing circuit of oil sprayer driving currents

A technology for collecting, processing and driving current, which is applied in the direction of machines/engines, instruments, engine components, etc., can solve the problems of poor transmission anti-interference ability, high cost of current clamp, and large interference of switching circuits, etc., and achieve reliable isolation effect and low cost , compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

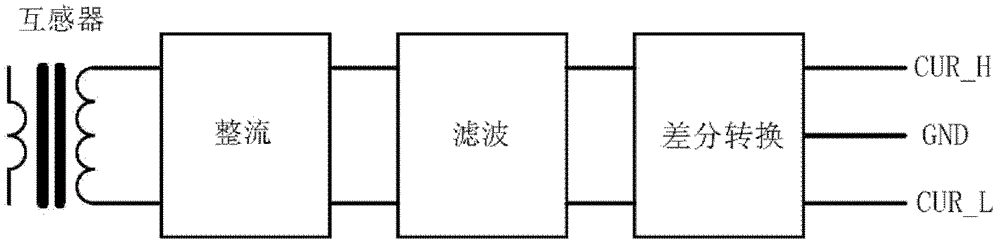

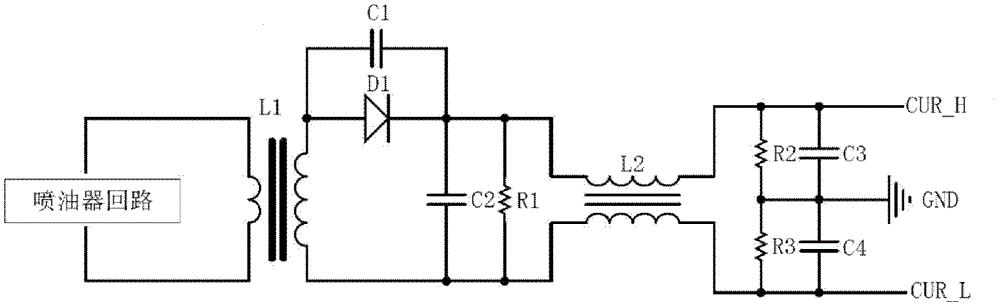

[0017] see figure 1 As shown, the fuel injector drive current acquisition and processing circuit is composed of four parts: current transformer, rectifier circuit, filter circuit and differential conversion circuit; through reasonable circuit design, the drive current of the fuel injector under test is passed through the current transformer After coupling, rectification, filtering and differential conversion, the collected current signal is output as a differential voltage.

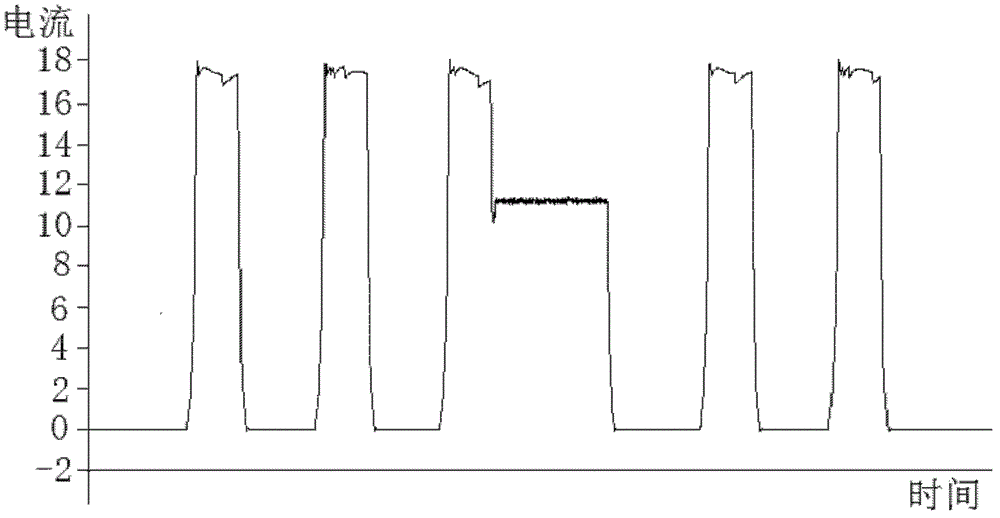

[0018] Since the transformer is used to couple the collected current, it will not affect the normal operation of the fuel injector and has a good isolation effect. The collected current signal is transmitted in differential mode, which has good anti-interference ability. For the output current waveform diagram in the practical application of the fuel injector drive current acquisition and processing circuit, see figure 2 As shown in the figure, the figure shows the 5 injection current waveforms of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com