Dynamic measurement device of oil leakage of turbocharger and measurement method thereof

A turbocharger, dynamic measurement technology, applied in the direction of measurement device, volume measurement instrument/method, measurement capacity, etc., can solve the problem of not being able to detect the sealing performance of the supercharger sealing structure, saving test costs and reducing test difficulty , the effect of expanding the scope of research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

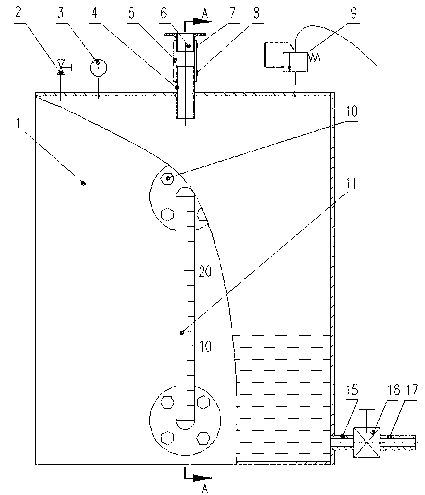

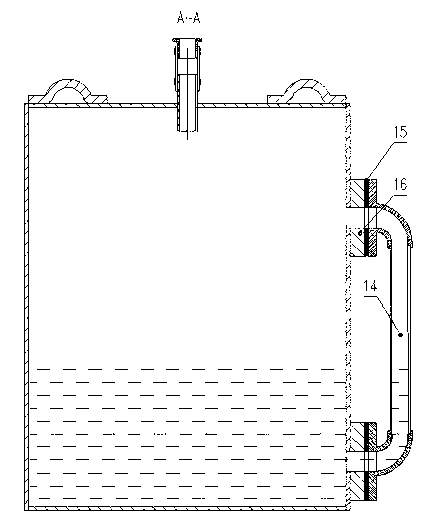

[0017] Preferred embodiment of the present invention is described further below in conjunction with accompanying drawing: preferred embodiment of the present invention is shown in Fig. 1, a kind of turbocharger oil leakage dynamic measuring device, it comprises: surge tank 1, exhaust pipe 2. Pressure fine-tuning valve 3, connecting pipe 4, pressure sensor 5, oil return pipe 6, transparent rubber pipe 7, supercharger oil return flange 8, first clamp 9, second clamp 10, pressure reducing valve 11, Intake pipe 12, screw 13, liquid level gauge 14, rubber pad 15, liquid level gauge fixed plate 16, oil discharge pipe 7, oil discharge valve 18, flow meter 19 and the booster under test, the surge tank 1 is an airtight container , the top of the surge tank 1 is sequentially provided with an exhaust pipe 2, a connecting pipe 4, an oil return pipe 6 and an air intake pipe 12, the inlet of the pressure trim valve 3 is connected to the exhaust pipe 2, and the outlet of the pressure trim val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com