Detection device for pipe corrosion conditions

A detection device and pipeline technology, which is applied in the direction of material analysis using radiation, can solve the problems of cumbersome disassembly and assembly of the clamping device, heavy workload of flaw detection equipment, and low work efficiency, so as to improve the stability of the device and increase the clamping force , high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

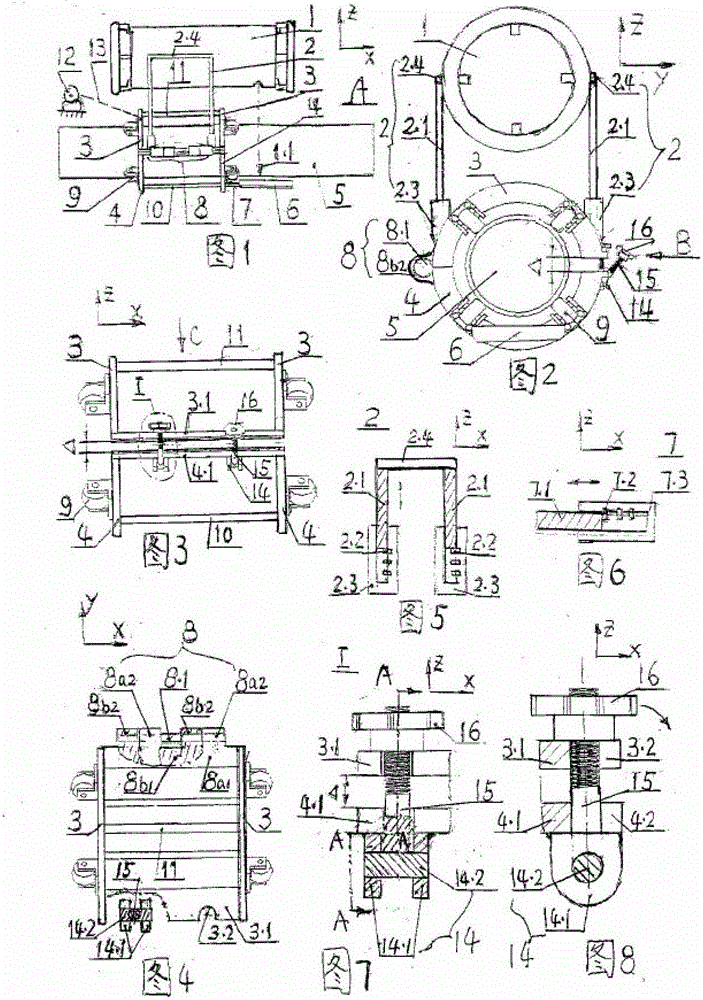

[0023] See figure 1 , figure 2 In this embodiment, the pipeline corrosion detection device is formed as follows: the X-ray machine 1 placed above the pipeline 5 adopts a cermet tube portable X-ray machine, and the detection flat panel 6 placed on the outer bottom of the pipeline adopts an amorphous silicon flat panel detector.

[0024] See figure 1 , image 3 , a clamping ring assembled on the outer circumference of the pipe 5 is respectively arranged on the front and rear ends of the pipe in the axial direction X (see item 3 and item 4 at both ends). See figure 2 , each group of clamping circles has an upper half circle 3 and a lower half circle 4, and each group of upper half circles and lower half circles is connected by a hinge connection 8 along one end of the horizontal Y. The other end is an opening, and there is a gap Δ in vertical Z. See image 3 , there are upper connecting plate 3.1 and lower connecting plate 4.1 respectively between the two upper half circl...

Embodiment 2

[0030] Embodiment 2: This embodiment 2 is identical to embodiment 1 except for the following features.

[0031] See figure 1 , establish the motor 12 and the transmission rope 13, one end of the transmission rope is connected to the output shaft of the motor, and the other end is fixed on the upper half circle or the lower half circle, or is fixed on the upper half circle and the lower half circle at the same time. The number of rotations and the shrinkage length of the transmission rope can be set in the motor according to the length of the pipeline to be tested, and the motor can be controlled to automatically roll axially to detect the corrosion status of the full-length pipeline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com