Moveable-feeding-mechanism-based ultrasonic flaw detection system for bent steel tubes

A feeding mechanism and mobile technology, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and measuring devices. It can solve the problem that the detection speed and detection accuracy cannot meet the large quantities of enterprises Regardless of production requirements, low detection efficiency, cumbersome process, etc., to improve the efficiency of ultrasonic detection, reduce labor intensity, and achieve simple motion control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

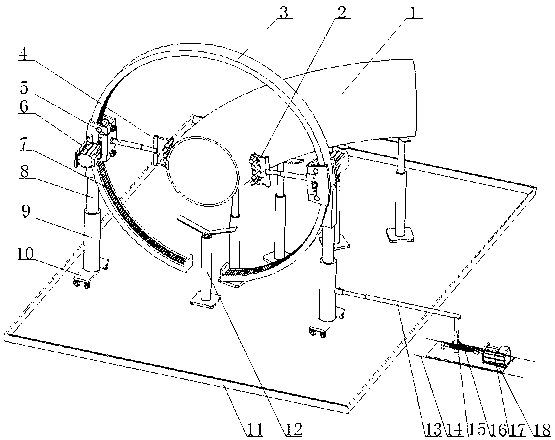

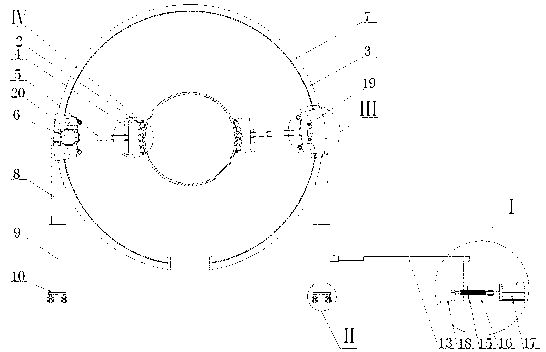

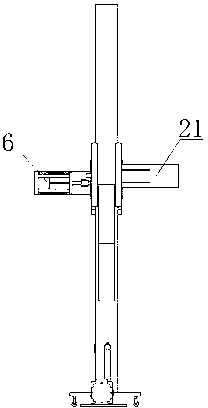

[0029] combine figure 1 As shown, the present invention includes a movable ring feed mechanism, a bent pipe holding base and two sets of bent pipe ultrasonic detection mechanisms with the same structure. The mobile ring feed mechanism includes a ring guide rail 3, an internal gear 7, a feed pneumatic telescopic rod 13, a drive worm 16, a drive worm wheel 22, a drive rod 15, a first motor mounting plate 18, an adjustment track 14 and a feed servo motor 17 , two roller mounting plates 10 and two hydraulic support cylinders 9, the elbow holding base includes a group of hydraulic support all consisting of a hydraulic cylinder 12, a hydraulic piston rod 32 and a V-shaped support frame 33 installed on the hydraulic piston rod 32 Two sets of bending pipe ultrasonic testing mechanisms with the same structure include detection servo motor 6, outer box body 20 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com