Polymer stable vertical alignment liquid crystal display panel and liquid crystal display

A technology for stabilizing vertical alignment, liquid crystal display panels, applied in liquid crystal materials, ester copolymer adhesives, instruments, etc., can solve problems such as panel light leakage, and achieve the effect of reducing light leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

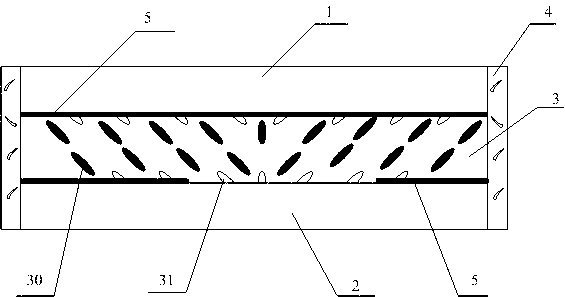

[0037] Such as figure 1 As shown, a schematic diagram of a polymer stabilized vertical alignment liquid crystal display panel of the present invention is shown. The liquid crystal display panel includes: a first substrate 1, a second substrate 2, a liquid crystal layer 3 sandwiched between the two substrates, and The frame adhesive material 4 that seals the liquid crystal in the two substrates. Wherein, an ITO electrode 5 is further provided on the opposite side of the first substrate 1 and the second substrate 2 . The liquid crystal layer contains at least liquid crystal molecules 30 and polymerizable monomers. When the ITO electrodes 5 are connected, the polymerizable monomers form bumps (protrusions) 31 on the first substrate 1 and the second substrate 2, wherein , the molecular weight of the polymerizable monomer in the liquid crystal layer is less than 500, wherein the polymerizable monomer is selected from at least one of the following general structural formulas:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com