Keyboard module and manufacturing method thereof

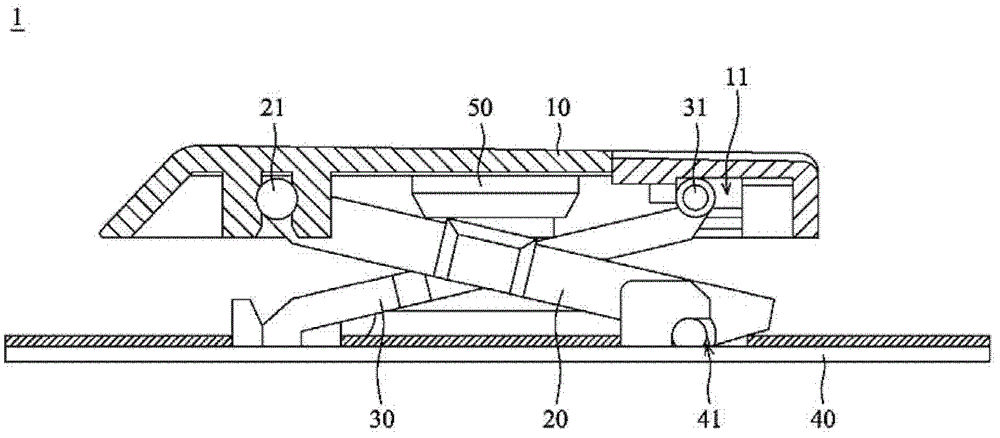

A technology of a keyboard module and a manufacturing method, which is applied in the field of thin keyboard modules, can solve the problems of obstructing the thinning of the keyboard module and increasing the complexity of assembly procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the above and other objects, features and advantages of the present invention more comprehensible, specific embodiments are exemplified below and described in detail in conjunction with the accompanying drawings.

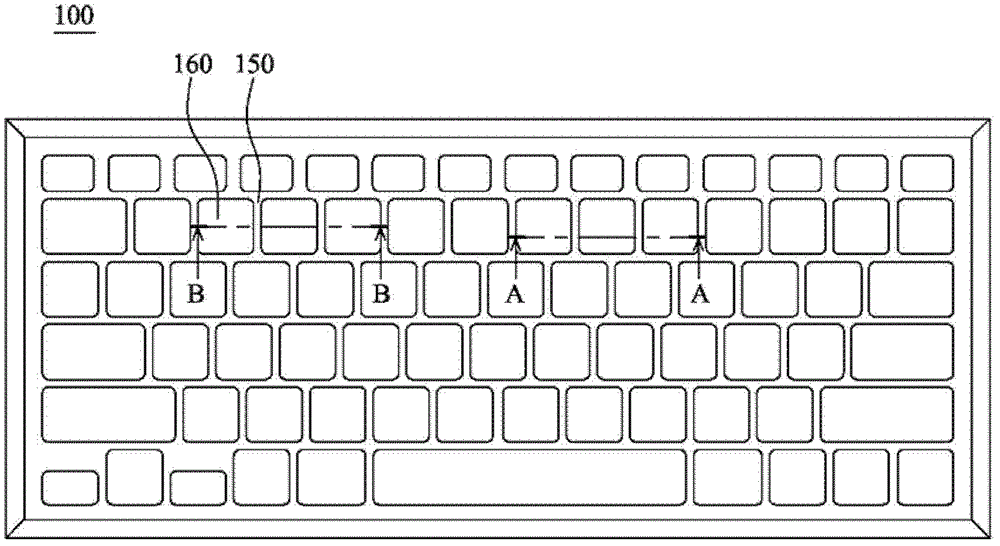

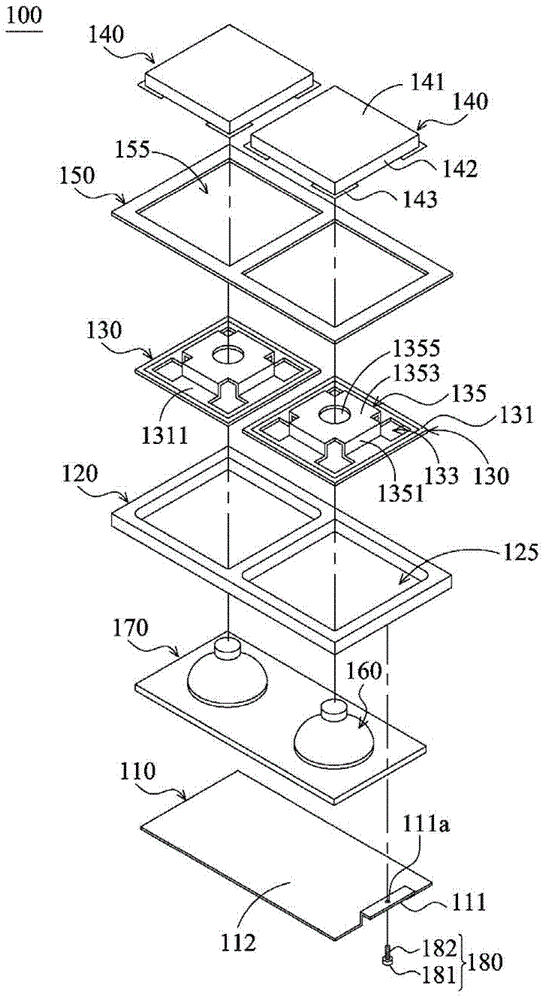

[0034] See Figure 2-6 ,in Figure 5 for figure 2 The sectional view taken along the A-A section line; Figure 6 for figure 2 The cross-section view along the B-B section line. To simplify the diagram, in image 3 Only part of the structure of the components 110, 120, 150, 170 is drawn in the drawing, which is specified here in advance.

[0035] The keyboard module 100 of the preferred embodiment of the present invention includes a base 110, a support frame 120, a plurality of maintaining members 130, a plurality of keycaps 140, a bezel 150, a plurality of elastic members 160, a circuit board 170 and a plurality of 180 bolts. The base 110 includes at least one setting slot 111 and a flat plate 112 . The setting groove 111 protrudes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com