High-pressure discharge lamp having a reference ring, and method for producing the high-pressure discharge lamp

A high-pressure discharge lamp technology, which is applied in the manufacture of discharge tubes/lamps, discharge lamps, electrode systems, etc., can solve the problems of difficulty in accurately maintaining the thickness, increased unit cost, and increased scrap rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

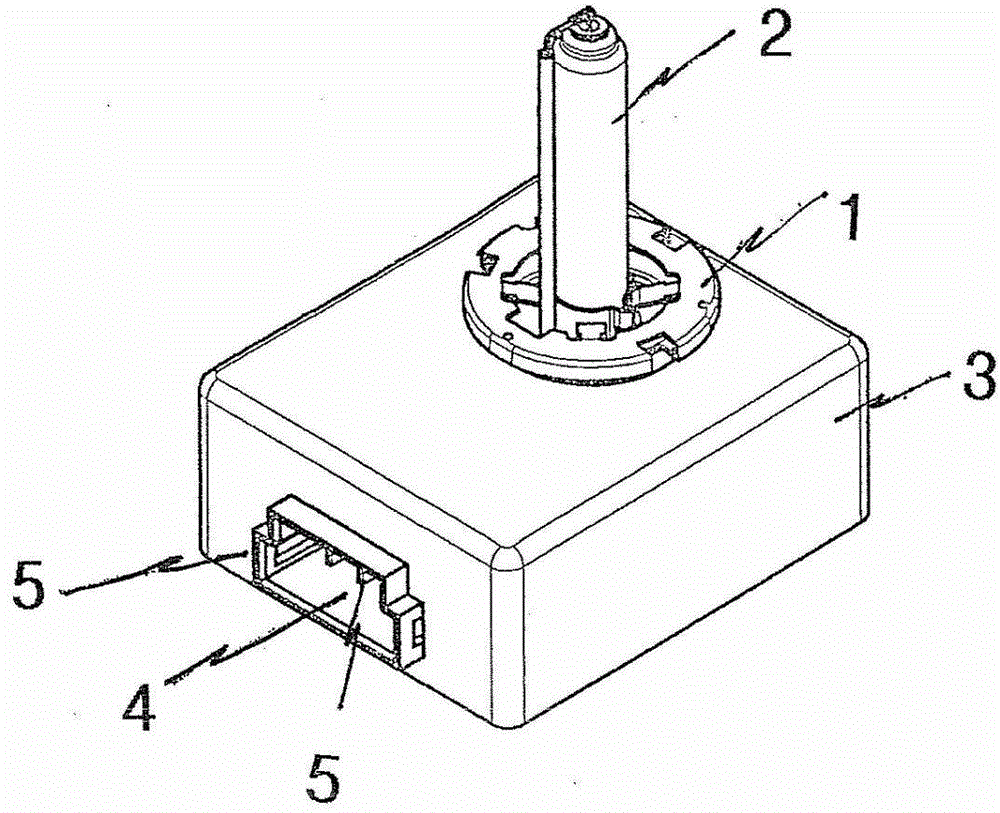

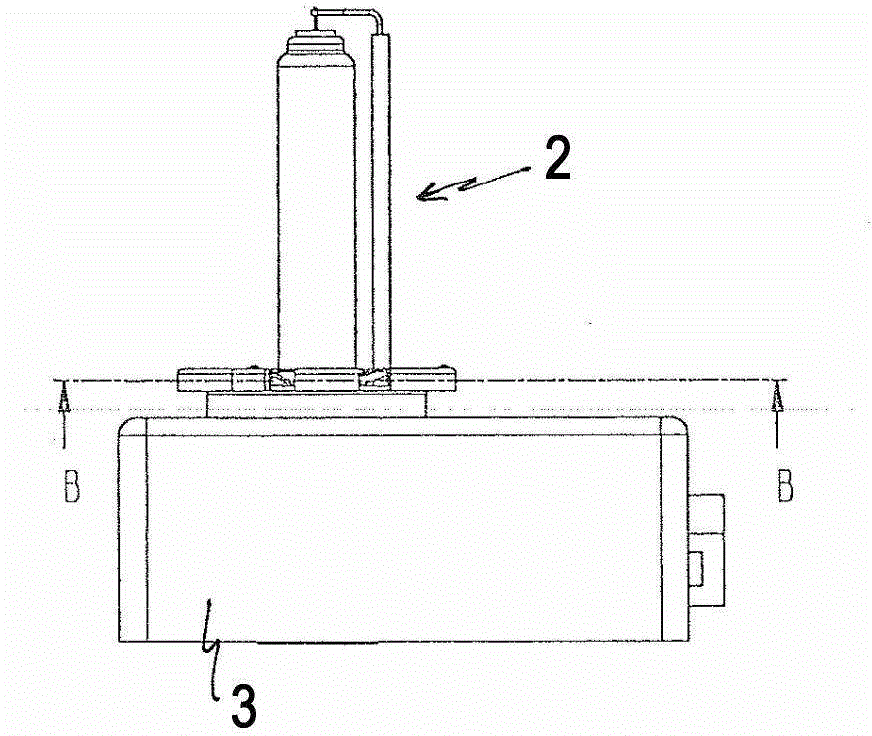

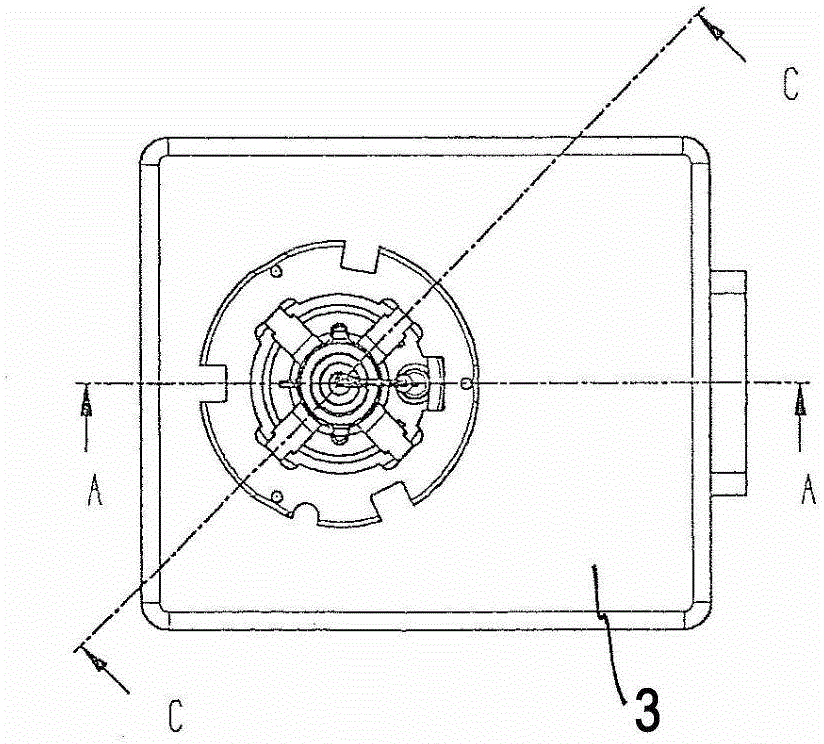

[0030] according to figure 1 , the D lamp of the preferred embodiment of the invention has a metal reference ring 1 in which the burner 2 is firmly fixed in a certain relative position and fixed on the housing 3 of the electronic module not further shown in the figure .

[0031] The housing 3 preferably has the ignition electronics of the D lamp (not shown in the figure) and has connection wells (Anschlussschacht) 4 for the electrical connection of the D lamp to a power supply (not shown in the figure) Contact pin 5 protrudes into it, which as in the figure 1 and Figure 4 shown in .

[0032] The burner 2 comprises a discharge vessel 7 and an outer bulb 6 which surrounds the discharge vessel 7 and is fixed beside the discharge vessel 7. The inner space of the discharge vessel comprises two electrodes arranged opposite each other and xenon gas and a metal halide for generating a gas discharge things. On an end section of the cylindrical outer bulb 6 , a sleeve-like metal b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com