Positioning fixture for high-precision honing of inner hole of valve pocket

A technology for honing processing and positioning fixtures, which can be used in honing machine tools, manufacturing tools, metal processing equipment, etc., and can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

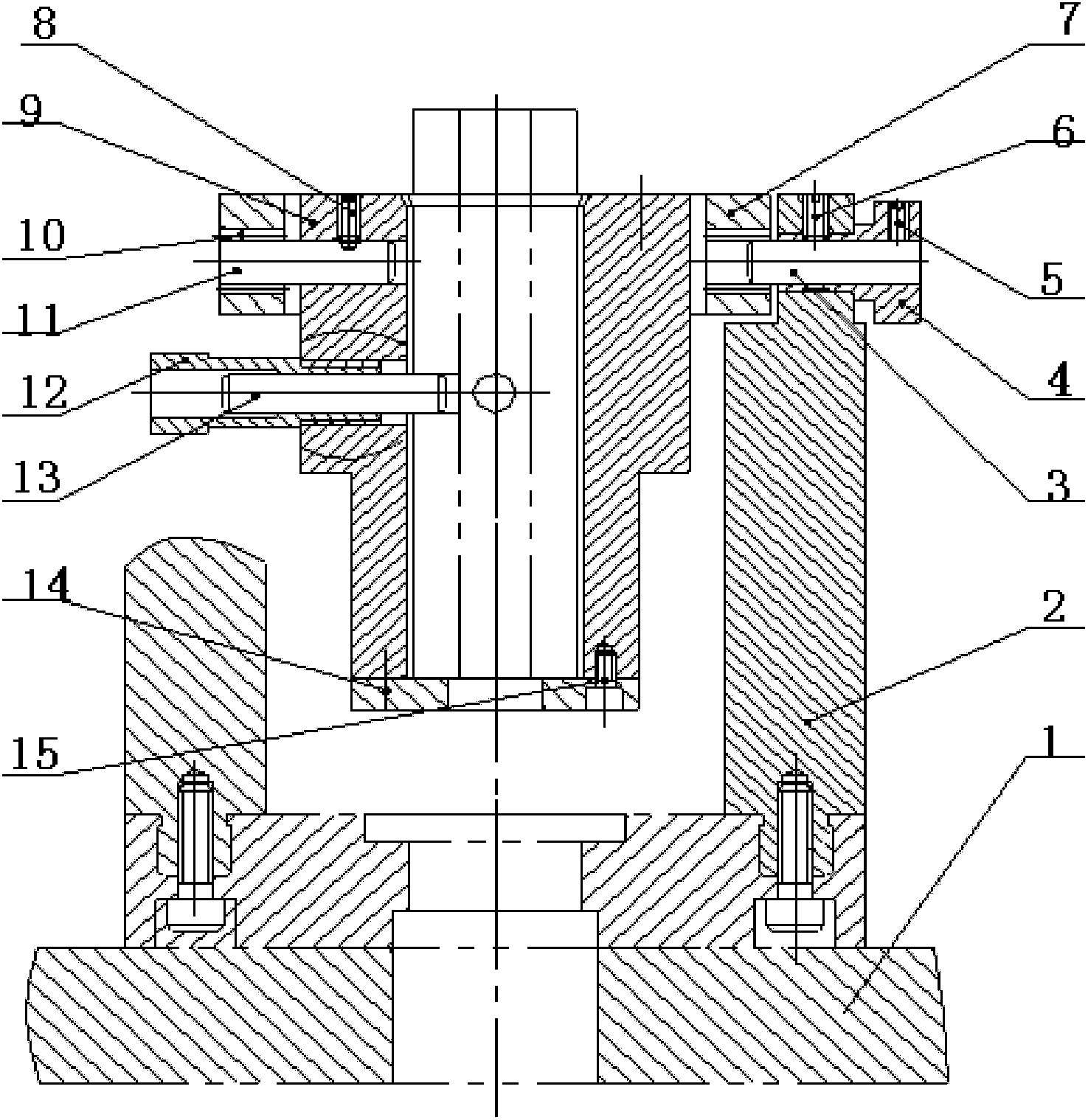

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0018] The present invention includes a base 1, a pair of uprights 2, a pair of positioning sleeve pins 3, a pair of pins 11 of the clamping body, a pair of handwheels 4, a positioning sleeve 7, four roller nail bearings 10, a clamping body 9, a positioning pallet 14, Fastening screw 12 and valve sleeve positioning pin 13.

[0019] The bottom of clamp body 9 is fixedly connected with positioning pallet 14 by screws 15 . The positioning sleeve 7 is uniformly provided with four radially extending through-holes along the circumferential direction, and the four nail bearings 10 are respectively pressed into the four through-holes to be fixed with the positioning sleeve 7 . The positioning sleeve 7 is set outside the clamp body 9, and a pair of clamp body pins 11 are respectively inserted into the two roller nail bearings 10 oppositely arranged am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com