Extrusion filter

A filter and filter technology, which is applied in the field of plastic granulators, can solve the problems of equipment not working normally, labor-intensive, time-consuming, and low production efficiency, and achieve simple and easy waste removal, long service life and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

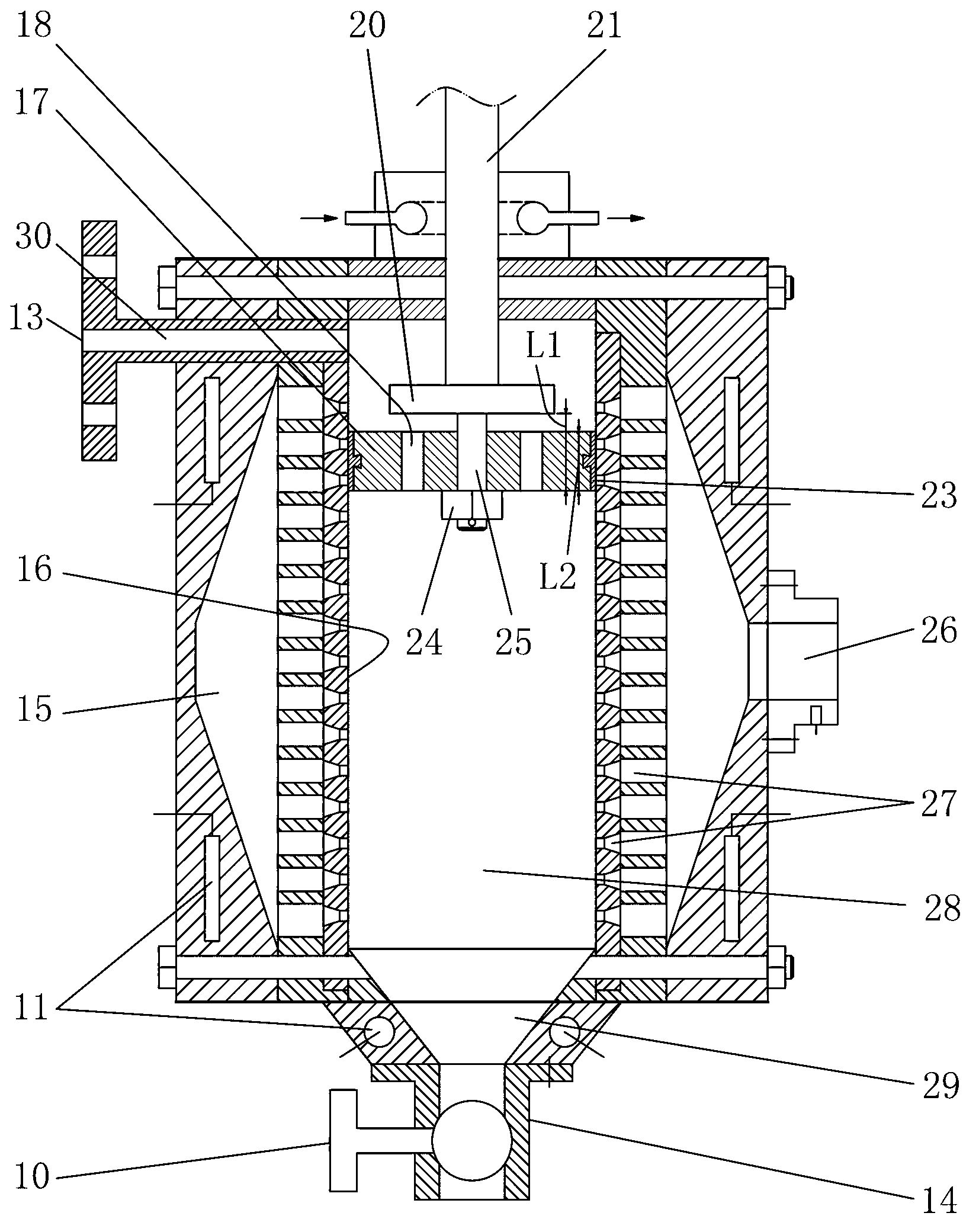

[0017] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 :

[0018] Squeeze filter, including shell, feeding joint arranged on the shell, heating temperature control device and extruding device, the impurity filter 12 with filter net is connected on the discharge port 13 of extruding device, The impurity filter 12 inner cavity 28 is provided with a scraping and impurity removal device that scrapes the impurities on the filter net into the impurity storage cavity 29 and can be discharged to the outside of the impurity filter 12. The inner cavity side wall of the impurity filter 12 is provided with Several radially arranged filter holes 27 form a filter screen, and the outer wall of the impurity filter 12 is provided with a discharge joint 26 communicating with the discharge chamber 15 outside the filter screen.

[0019] The specific structure of the above-mentioned scraping and miscellaneous d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com