Molding device and preparation method for long fiber-reinforced nylon

A molding device and long fiber technology, which is applied in the field of molding device and preparation of long fiber reinforced nylon, can solve the problems of affecting product color stability, poor self-cleaning performance, and reducing production efficiency, so as to improve product color stability and production efficiency , Improve product color stability and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

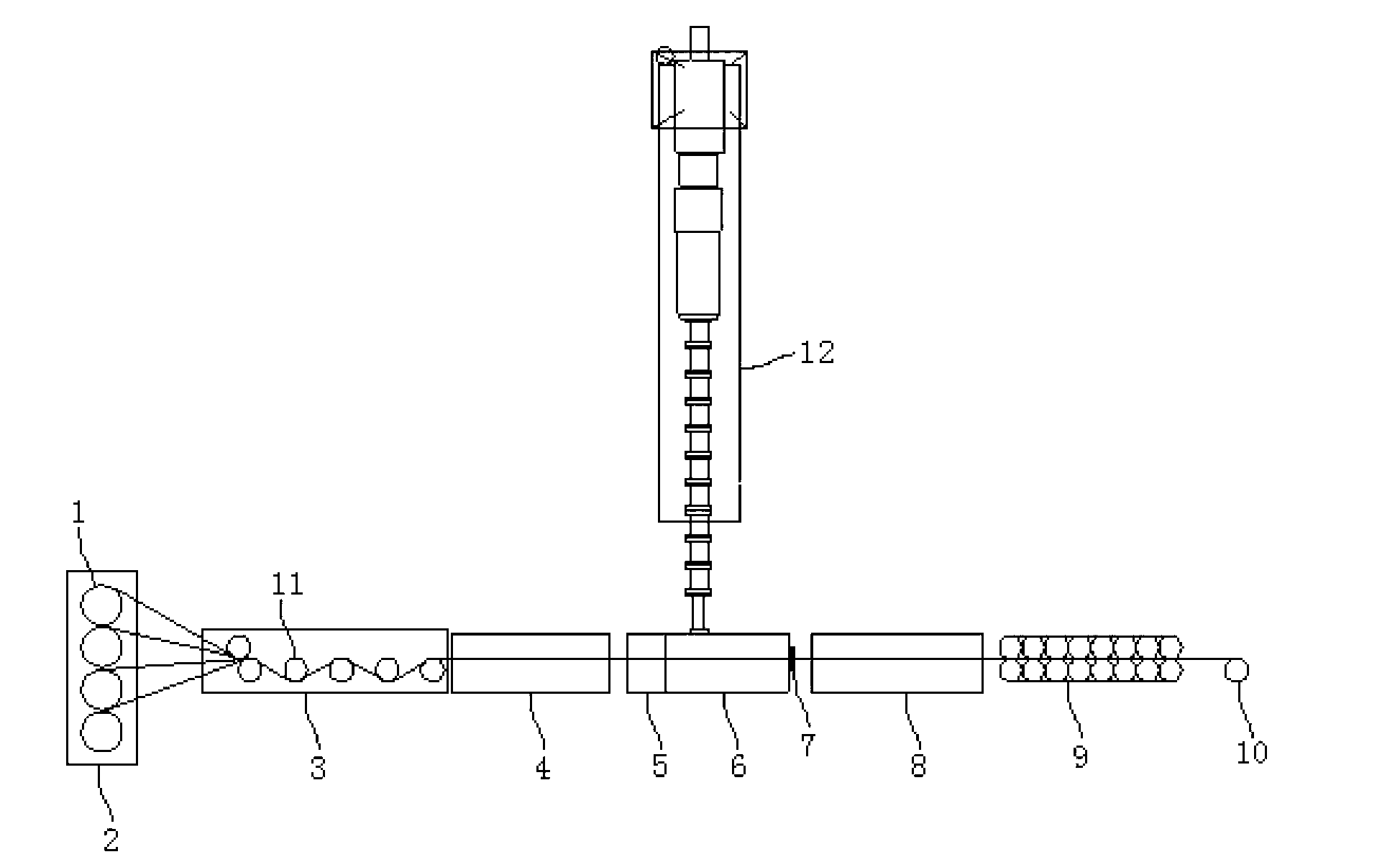

[0041] In Example 1, the overall structure schematic diagram of the molding device used is as follows figure 1 As shown, among them, the glass fiber 1 is drawn out from the creel 2, and after being flattened, it enters the tension regulator 3, and the inside of the tension regulator 3 is provided with a number of tension rollers 11 to adjust the tension of the glass fiber. 1 is preheated in the preheating device 4; then sent to the component 5 for inert gas protection, the component 5 for inert gas protection is an inert gas air curtain machine, and the air outlet of the air curtain machine is transported with the glass fiber 1 The channels are connected, and the air outlet of the air curtain machine continuously outputs inert gas to form an air curtain, through which the inert gas air curtain can prevent the air contained in the glass fiber 1 delivery channel from entering the impregnation head, and play the role of inert gas protection . Under the protection of inert gas, t...

Embodiment 2

[0043] In embodiment 2, the overall structure schematic diagram of the molding device used is as follows figure 1 As shown, among them, the glass fiber 1 is drawn out from the creel 2, and after being flattened, it enters the tension regulator 3, and the inside of the tension regulator 3 is provided with a number of tension rollers 11 to adjust the tension of the glass fiber. 1 is preheated in the preheating device 4; then sent to the part 5 protected by inert gas, which is a sealing member including at least one gas inlet. The seal includes a housing, an air inlet arranged on the housing, and a channel for inert gas flow inside the housing; the channel for inert gas flow communicates with the glass fiber 1 delivery channel. The inert gas enters the inside of the seal from the air inlet, and fills the channel for the flow of the inert gas, so that the glass fiber 1 is protected by the inert gas when passing through the inside of the seal, and at the same time prevents the air ...

Embodiment 3

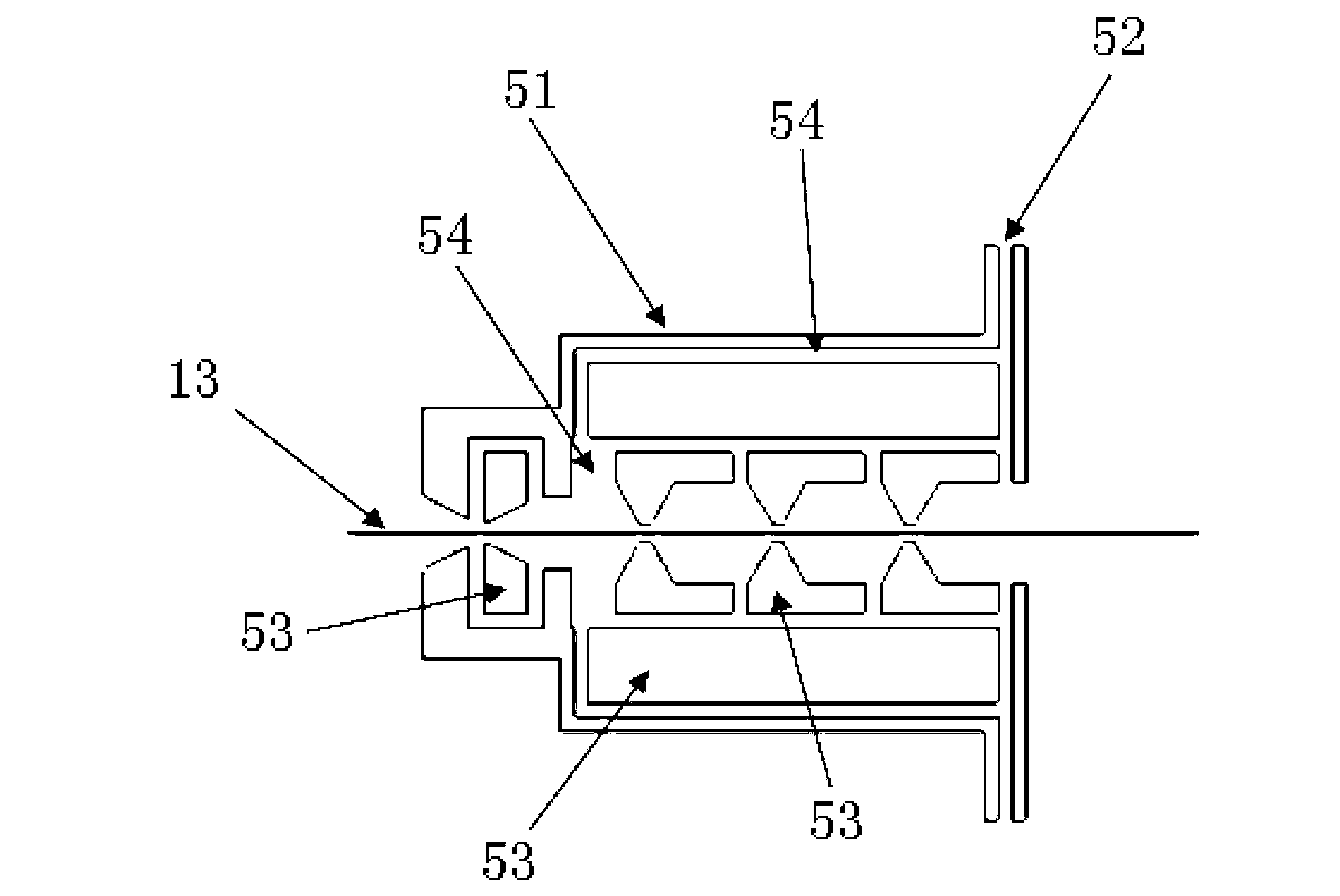

[0045] In embodiment 3, the overall structure schematic diagram of the molding device used is as follows figure 1As shown, among them, the glass fiber 1 is drawn out from the creel 2, and after being flattened, it enters the tension regulator 3, and the inside of the tension regulator 3 is provided with a number of tension rollers 11 to adjust the tension of the glass fiber. 1 is preheated in the preheating device 4; then sent to the part 5 under inert gas protection, the part 5 under inert gas protection is a labyrinth seal, the structure of the labyrinth seal can refer to the labyrinth of the prior art seals. The structural diagram of the labyrinth seal can be as follows figure 2 shown. The labyrinth seal includes a housing 51, an air inlet 52 disposed on the housing, a labyrinth unit 53 disposed inside the housing, and a channel 54 disposed inside the housing for inert gas flow; The channel 54 communicates with the glass fiber 1 delivery channel 13 . The inert gas ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com