Method for encapsulating crystalline silicon solar cell component

A technology of solar cells and encapsulation methods, applied in the field of solar photovoltaics, can solve problems such as aging and yellowing, and achieve the effects of delaying yellowing, improving photoelectric conversion efficiency, and extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

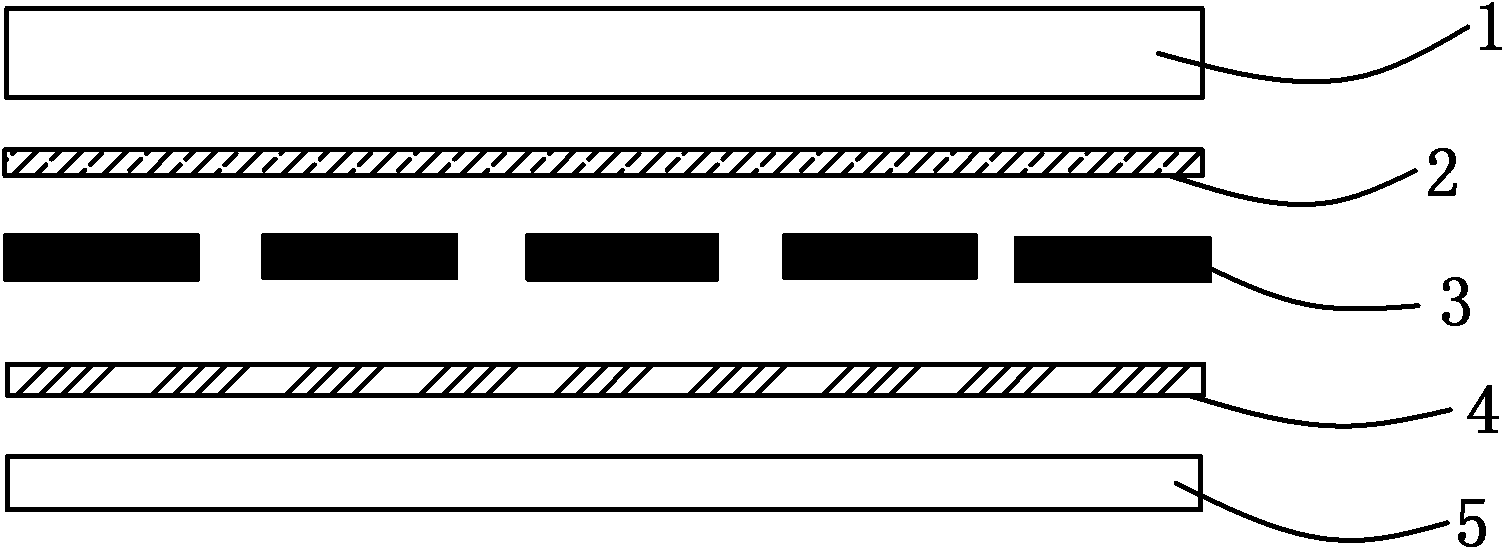

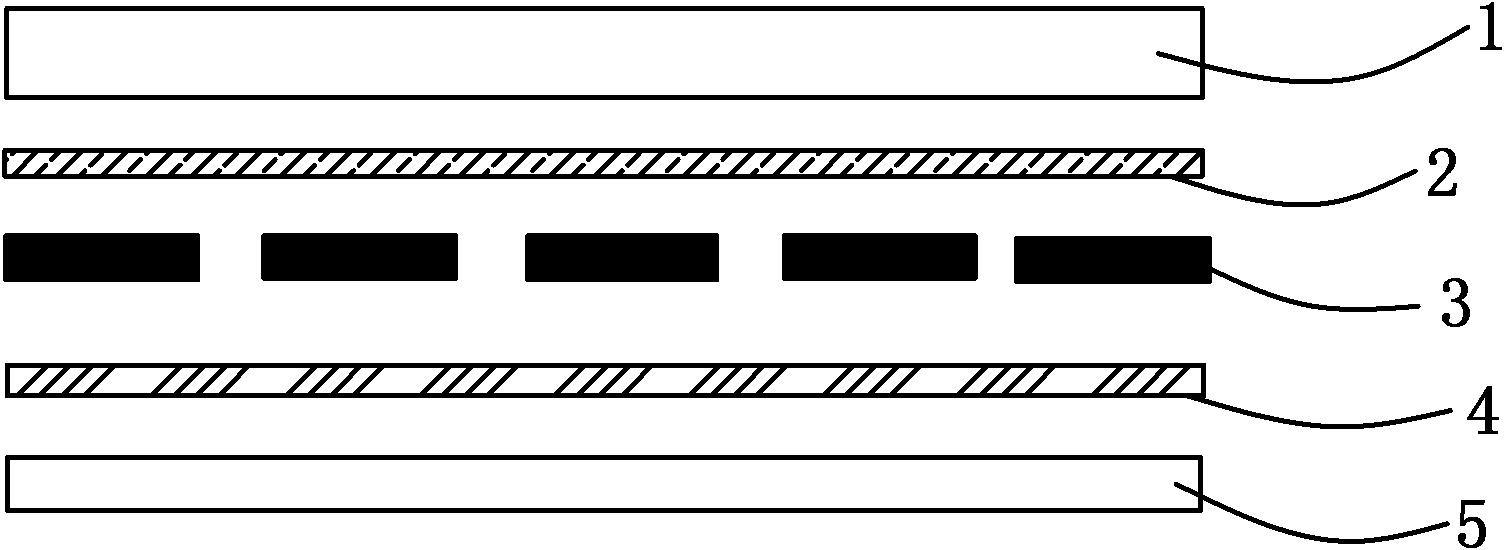

[0026] Example 1. A method for encapsulating a crystalline silicon solar cell assembly, which comprises laminating tempered glass 1, A-type EVA adhesive film 2, crystalline silicon solar cell 3, B-type EVA adhesive film 4, and PET back plate 5, heating and vacuumizing Compression packaging, the side facing the sun uses A-type EVA film with high light transmittance, and the other side uses B-type EVA film that absorbs and blocks ultraviolet rays. The A-type EVA film, by weight, It is composed of 95% EVA resin and 5% modified additive a; the EVA resin is high light transmittance EVA resin PV1200 with a VA content of 33%. The formula of modified additive a is: by weight, by 1.5 parts of organic peroxide crosslinking agent, 2 parts of crosslinking auxiliary agent, 0.8 part of silane coupling agent, 0.3 part of light stabilizer and 0.2 part of antioxidant composition.

[0027] The B-type EVA adhesive film is composed of 95% EVA resin and 5% modified additive b in parts by weight;...

Embodiment 2

[0029] Example 2. A method for encapsulating a crystalline silicon solar cell assembly, which comprises laminating tempered glass 1, A-type EVA adhesive film 2, crystalline silicon solar cell 3, B-type EVA adhesive film 4, and PET back plate 5, heating and vacuumizing Compression packaging, the side facing the sun uses A-type EVA film with high light transmittance, and the other side uses B-type EVA film that absorbs and blocks ultraviolet rays. The A-type EVA film, by weight, It is composed of 95% EVA resin and 5% modified additive a; the EVA resin is high light transmittance EVA resin EV150 with VA content of 33%. The formula of modified additive a is: by weight, by 1.49 parts of organic peroxide crosslinking agent, 1.99 parts of crosslinking auxiliary agent, 0.99 part of silane coupling agent, 0.28 part of light stabilizer and 0.25 part of antioxidant composition.

[0030] The B-type EVA adhesive film is composed of 95% EVA resin and 5% modified additive b in parts by wei...

Embodiment 3

[0034] Example 3. A method for encapsulating a crystalline silicon solar cell assembly, which comprises laminating tempered glass 1, A-type EVA adhesive film 2, crystalline silicon solar cell 3, B-type EVA adhesive film 4, and PET back plate 5, heating and vacuumizing Compression packaging, the side facing the sun uses A-type EVA film with high light transmittance, and the other side uses B-type EVA film that absorbs and blocks ultraviolet rays. The A-type EVA film, by weight, It is composed of 95% EVA resin and 5% modification additive a; the EVA resin is high light transmittance EVA resin MA-10 with VA content of 33%. The formula of modified additive a is: in parts by weight, composed of 1 part of organic peroxide crosslinking agent, 1 part of crosslinking auxiliary agent, 1 part of silane coupling agent, 1 part of light stabilizer and 1 part of antioxidant composition.

[0035] The B-type EVA adhesive film is composed of 95% EVA resin and 5% modified additive b in parts b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com