Advanced sewage treatment device

A technology of advanced treatment and sewage, applied in the field of water treatment, can solve the problems of difficult to meet the water quality requirements of reused water, low operating costs, long treatment process, etc., to achieve good effluent quality, reduce load and dosage, and improve effluent quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

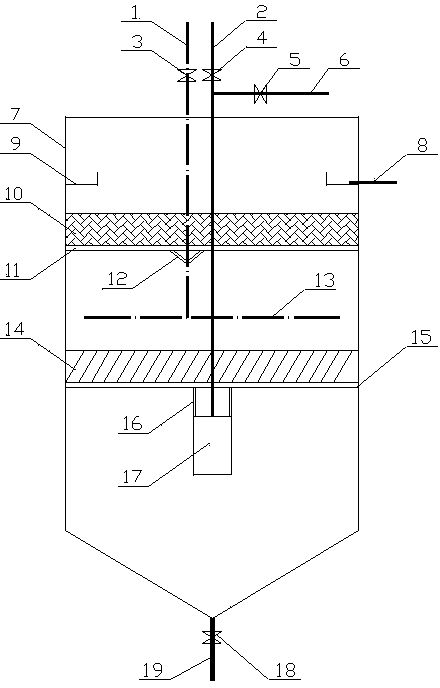

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] see figure 1 , an embodiment of a sewage advanced treatment device of the present invention, the shell 7 is made of a stainless steel plate of a certain thickness into a circular cylinder, the upper end is open, the lower end is a cone head, and is supported by the base. A slant plate 14 and a slant plate support frame 15 are arranged in the lower part of the housing 7 , and the slant plate 14 is seated on the slant plate support frame 15 . A water distributor 17 is arranged at the inner center of the lower housing 7 of the inclined plate support frame 15, and the water distributor 17 is fixed by the water distributor fixed frame 16, and the water distributor fixed frame 16 is connected with the inclined plate support frame 15 bottoms. The upper inner side of the shell 7 is provided with an annular upper open-type sump 9, and an outlet pipe 8 is connected ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com