Novel cement grinding aid and preparation method thereof and application thereof

A cement grinding aid and cement technology, applied in the field of cement admixtures, can solve the problems of ineffective reduction of lattice cohesion, weak surface adsorption of solid particles, and low grinding efficiency of cement grinding aids. The effect of material stickiness, compressive strength improvement, and time increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] First add 670g of water to the reaction pot, start stirring and add 150g of commercially available polymerized mixed fat, 100g of molasses, 100g of diethanol monoisopropanolamine, and 30g of triethanolamine, and stir for 2 hours to obtain the finished product.

Embodiment 2

[0021] First add 460g of water to the reaction pot, start stirring and add 280g of commercially available polymerized mixed fat, 50g of molasses, 150g of diethanol monoisopropanolamine, and 90g of triethanolamine, and stir for 2 hours to obtain the finished product.

Embodiment 3

[0023] First, add 250g of water into the reaction pot, start stirring and add 400g of commercially available polymerized mixed fat, 250g of diethanol monoisopropanolamine, and 150g of triethanolamine, and stir for 2 hours to obtain the finished product.

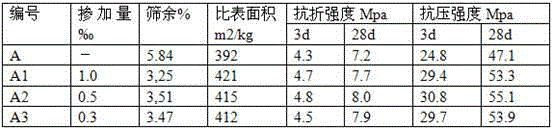

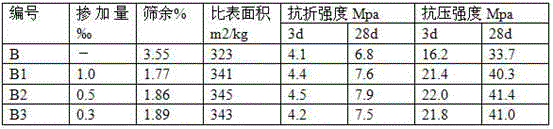

[0024] The cement grinding aid that example 1-3 is synthesized is applied small grinding test result as follows:

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com