A kind of cement grinding aid and preparation method thereof

A cement grinding aid and temperature control technology, which is applied in the field of cement admixtures, can solve the problems of cement grinding aids, such as obstacles to earn foreign exchange and increase efficiency, high price of raw materials, and insufficient compatibility of concrete admixtures. Wide and good grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

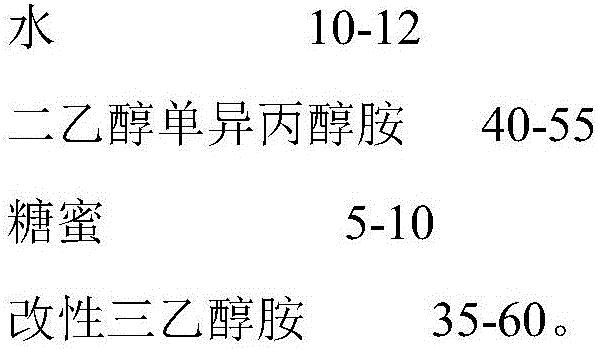

[0017] Preparation of cement grinding aid: add 10 mass parts of water, 55 mass parts of diethanol monoisopropanolamine, 10 mass parts of molasses, 60 mass parts of modified triethanolamine in the reactor, and increase the temperature in the reactor to Control the temperature at 90°C, react with rapid stirring for 2 hours, and then keep it warm for 1 hour to make cement grinding aid.

[0018] According to the mass ratio, 15% of the cement grinding aid prepared under the conditions of the above preparation method, 10% of glycerin, 20% of molasses, and 55% of water are selected; the materials are respectively added to the mixer according to the above ratio and stirred evenly. The mixing ratio is 1000 g / t cement.

Embodiment 2

[0020] Preparation of cement grinding aid: add 12 mass parts of water, 50 mass parts of diethanol monoisopropanolamine, 8 mass parts of molasses, 40 mass parts of modified triethanolamine in the reactor, and increase the temperature in the reactor to Control the temperature at 90°C, react with rapid stirring for 2 hours, and then keep it warm for 1 hour to make cement grinding aid.

[0021] According to the mass ratio, 33% of the cement grinding aid prepared under the conditions of the above preparation method, 18% of glycerin, 12% of molasses, and 37% of water were selected; the materials were added into the mixer according to the above ratio and stirred evenly. The mixing ratio is 500 g / t cement.

Embodiment 3

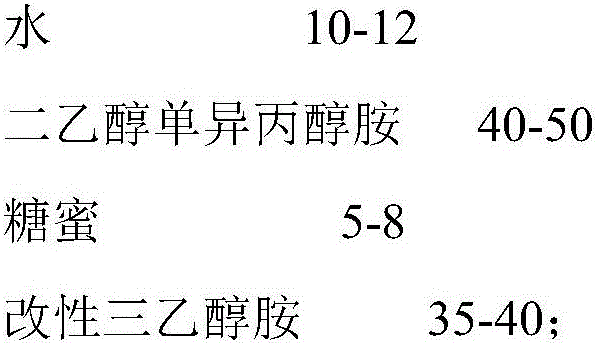

[0023] Preparation of cement grinding aid: add 10 mass parts of water, 40 mass parts of diethanol monoisopropanolamine, 5 mass parts of molasses, and 35 mass parts of modified triethanolamine in the reactor, and increase the temperature in the reactor to Control the temperature at 90°C, react with rapid stirring for 2 hours, and then keep it warm for 1 hour to make cement grinding aid.

[0024] According to the mass ratio, 49% of the cement grinding aid prepared under the conditions of the above preparation method, 20% of diethylene glycol, 5% of molasses, and 26% of water were selected, and the materials were added to the mixer according to the above ratio and stirred evenly. The mixing ratio is 300 g / t cement.

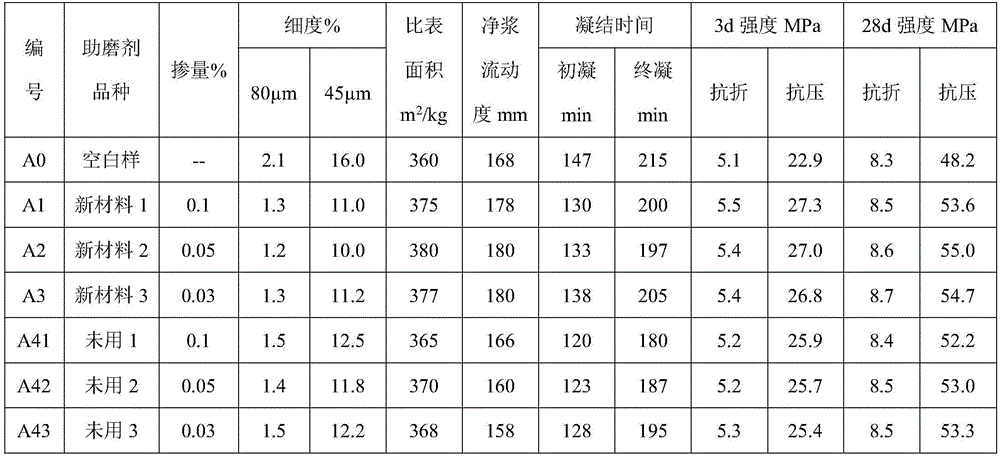

[0025] Ingredients comparison group A:

[0026] 8% triethanolamine, 7% triisopropanolamine, 10% glycerin, 20% molasses, 55% water; the mixing ratio is 1000 g / t cement.

[0027] 15% of triethanolamine, 18% of triisopropanolamine, 18% of glycerin, 12% of molasses, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com