Micro-surfacing mixture

A technology of micro-surfacing mixtures and mixtures, applied in the field of micro-surfacing mixtures and preparations, can solve problems such as poor low-temperature crack resistance and unsatisfactory anti-rutting ability, and achieve the effect of improving high-temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

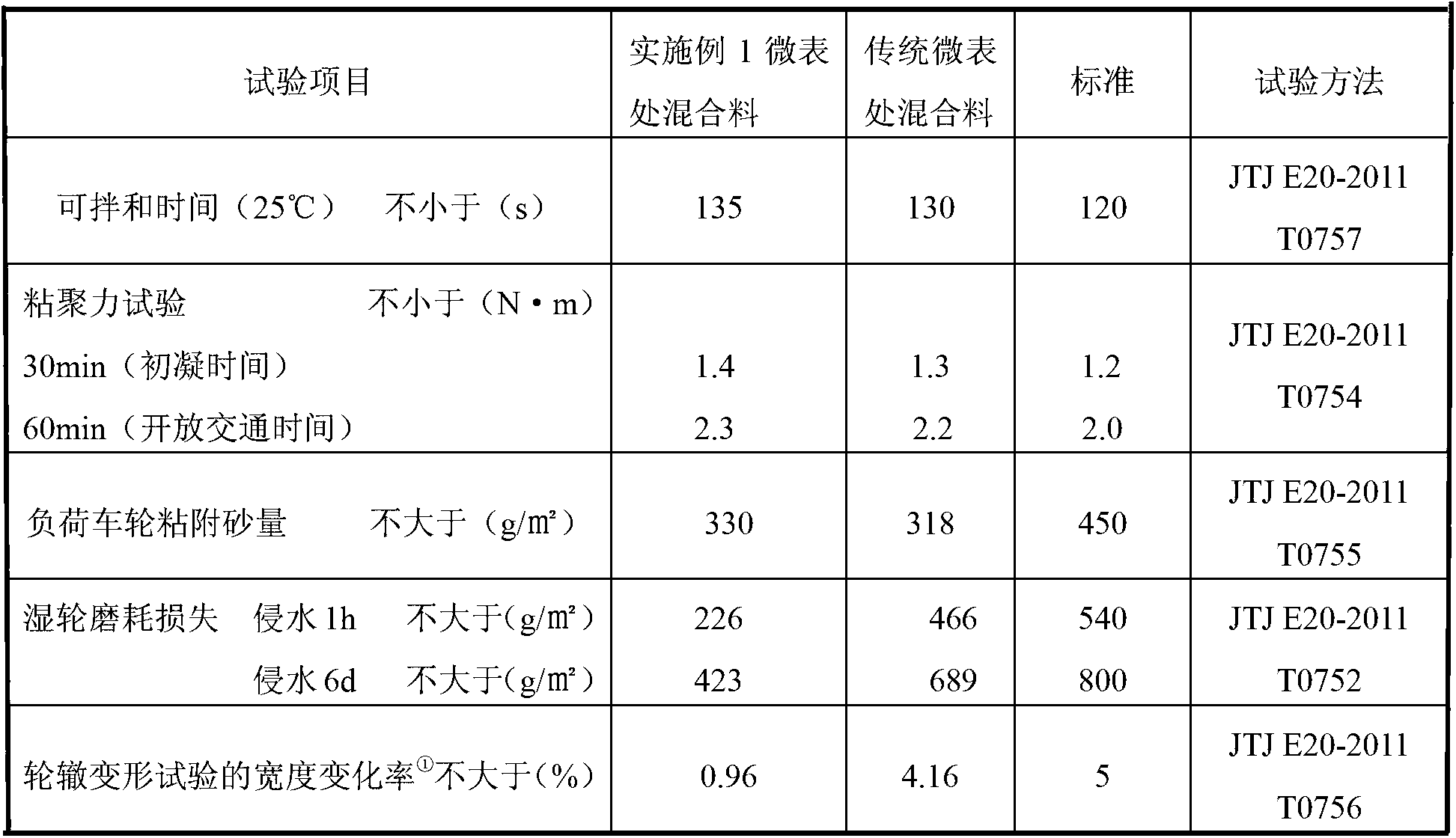

Embodiment 1

[0029] A kind of micro-surfacing mixture is prepared according to the following steps:

[0030]1. Preparation of high-elastic modified emulsified asphalt: SK70# base asphalt accounted for 65%, cationic slow-cracking and fast-setting emulsifier MQK-1D accounted for 1.8%, SBR latex accounted for 3.5%, SBS latex accounted for 3.5%, high-elasticity 1 No. modifier accounts for 1.75%, water accounts for 24%, stabilizer calcium chloride accounts for 0.15%, and polyvinyl alcohol accounts for 0.3%, calculated by mass percentage. Put the above-mentioned SK70# base asphalt on an electric donkey and heat it to 135-140°C; on the other hand, heat the water to 55-65°C, add the above-mentioned emulsifier and stabilizer to the water to obtain emulsifier soap, and put it in a water bath Keep warm at about 55-65°C, adjust the pH of the emulsifier soap to 1.5-2.5 with 34-36% hydrochloric acid solution in volume percentage; quickly pour the above-mentioned emulsifier soap into the emulsifier collo...

Embodiment 2

[0058] A kind of micro-surfacing mixture is prepared according to the following steps:

[0059] 1. Preparation of high-elastic modified emulsified asphalt: SK70# base asphalt accounted for 62%, cationic slow-cracking and fast-setting emulsifier kzw-801U accounted for 2.0%, SBR latex accounted for 3.0%, SBS latex accounted for 5.0%, high-elastic No. 1 Modifier accounts for 1.0%, water accounts for 26.5%, and stabilizer calcium chloride accounts for 0.5%, calculated by mass percentage. Put the above-mentioned SK70# base asphalt on an electric donkey and heat it to 135-140°C; on the other hand, heat the water to 55-65°C, add the above-mentioned emulsifier and stabilizer to the water to obtain emulsifier soap, and put it in a water bath Keep warm at about 55-65°C, and adjust the pH of the emulsifier soap to 2.5-3.5 with 34-36% hydrochloric acid solution in volume percentage. Pour the above heat-preserved emulsifier soap liquid into the emulsifier colloid mill (Germany, model, AF ...

Embodiment 3

[0062] A kind of micro-surfacing mixture is prepared according to the following steps:

[0063] 1. Preparation of high-elastic modified emulsified asphalt: SK70# base asphalt accounted for 68%, cationic slow-cracking and fast-setting emulsifier JY-5R accounted for 1.6%, SBR latex accounted for 3.0%, SBS latex accounted for 3.0%, high-elastic No. 1 Modifier accounted for 2.0%, water accounted for 22%, stabilizer polyacrylamide accounted for 0.4%, calculated by mass percentage; put the above-mentioned SK70# base asphalt on an electric donkey and heat it to 135-140°C; on the other hand, put Heat the water to 55-65°C, add the above-mentioned emulsifier and stabilizer to the water to obtain an emulsifier soap, keep the water bath at about 55-65°C, and use 34-36 volume percent of the emulsifier soap % hydrochloric acid solution to adjust the pH to 1.5-2.5; quickly pour the above-mentioned emulsifier soap into the emulsifier colloid mill (Germany, model, AF 90S / 2H-12) and start the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com