A kind of preparation method of potassium-rich aged potato vinegar

A technology of aged mature vinegar and rich in potassium, which is applied in the field of preparation of mature potato vinegar rich in potassium, which can solve the problems of single variety of health-care vinegar and low added value of potato processing, and achieve soft sour taste, rich and harmonious fragrance, and rich sources of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

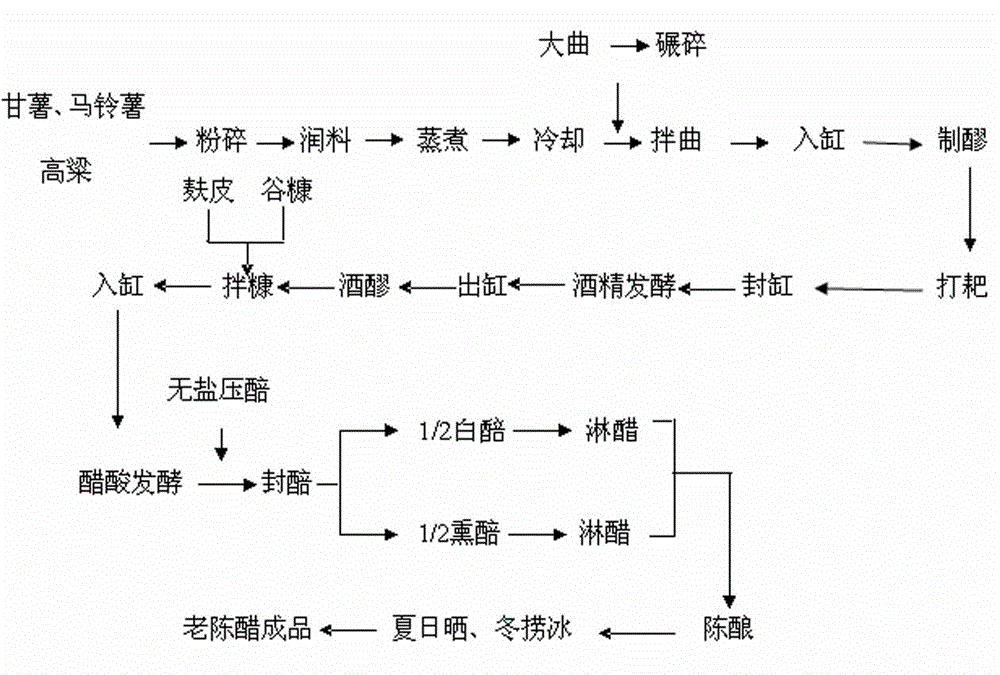

Image

Examples

Embodiment 1

[0035] A preparation method of potassium-rich mature potato vinegar, comprising the following steps:

[0036] (1) Saccharification and cooking of raw materials:

[0037] Add potatoes and sorghum with a mass ratio of 7:3 to 80°C hot water, add α-amylase, mix well in the hot water, add 5u / g, saccharify for 3 hours, and work at a working pressure of 0.15MPa. Steam until the sorghum and sorghum Potato cubes have no filling, are not sticky, stop the air supply, and the main food is obtained after steaming;

[0038] (2) Preparation of koji for vinegar:

[0039] Use barley, wheat and black soybeans with a mass ratio of 5:2:3 as koji-making raw materials, mix, pulverize, and add water. The weight ratio of koji-making raw materials to water is 1:2. Raw materials are used to make koji. The koji raw materials are connected to the solid-state fermentation equipment at a weight ratio of 1:48, the fermentation temperature is controlled at 30°C, the pH value is 5, and the blast volume is 7...

Embodiment 2

[0052] A preparation method of potassium-rich mature potato vinegar, comprising the following steps:

[0053] (1) Saccharification and cooking of raw materials:

[0054]Add potatoes and sorghum with a mass ratio of 7:3 to hot water at 85°C, add α-amylase and mix well in the hot water. Potato cubes have no filling, are not sticky, stop the air supply, and the main food is obtained after steaming;

[0055] (2) Preparation of koji for vinegar:

[0056] Use barley, wheat and black soybeans with a mass ratio of 5:2:3 as koji-making raw materials, mix, pulverize, and add water. The weight ratio of koji-making raw materials to water is 1:2.5. Raw materials are used to make koji. The koji raw materials are connected to the solid-state fermentation equipment at a weight ratio of 1:44, the fermentation temperature is controlled at 31°C, the pH value is 6, and the blast volume is 60m 3 / m 3 min, when the fermentation time reaches 31 hours, the koji is produced, and then the obtained...

Embodiment 3

[0069] A preparation method of potassium-rich mature potato vinegar, comprising the following steps:

[0070] (1) Saccharification and cooking of raw materials:

[0071] Add potatoes and sorghum with a mass ratio of 7:3 to hot water at 70°C, add α-amylase, mix well in the hot water, add 5u / g, saccharify for 3 hours, and work at a working pressure of 0.15MPa. Steam until the sorghum and Potato cubes have no filling, are not sticky, stop the air supply, and the main food is obtained after steaming;

[0072] (2) Preparation of koji for vinegar:

[0073] Use barley, wheat and black soybeans with a mass ratio of 5:2:3 as koji-making raw materials, mix, pulverize, and add water. The weight ratio of koji-making raw materials to water is 1:2.2. Raw materials are used to make koji. The koji raw materials are connected to the solid-state fermentation equipment at a weight ratio of 1:52, and the fermentation temperature is controlled at 32°C, the pH value is 7, and the blast volume is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com