Carbon-silicon-tungsten-yttrium lamellar structure high-niobium titanium-aluminum alloy and preparation method thereof

A titanium-aluminum alloy and microstructure technology, which is applied in the field of lamellar-structured high-niobium-titanium-aluminum alloys with carbon-silicon-tungsten-yttrium addition and its preparation, can solve the problems of insufficient oxidation resistance, poor plasticity, and limited wide application, and achieve good resistance to Oxidation and creep resistance, increased strength, precise parameter control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

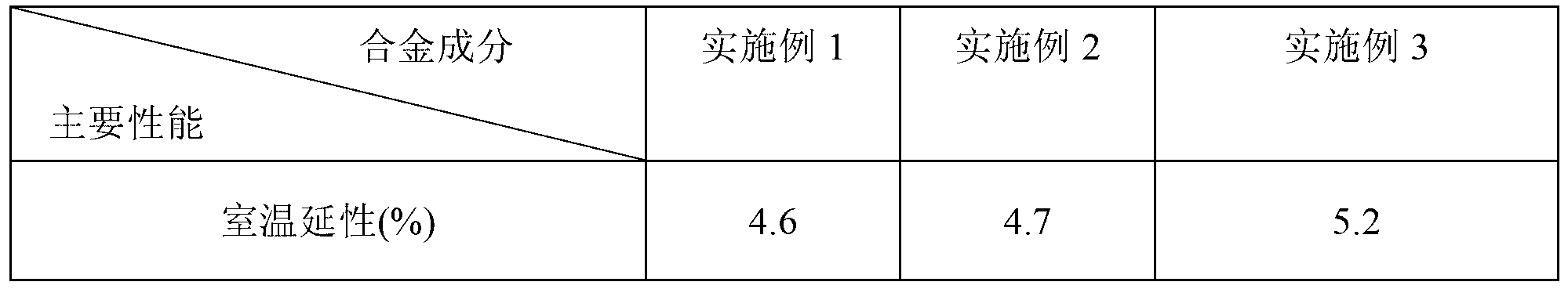

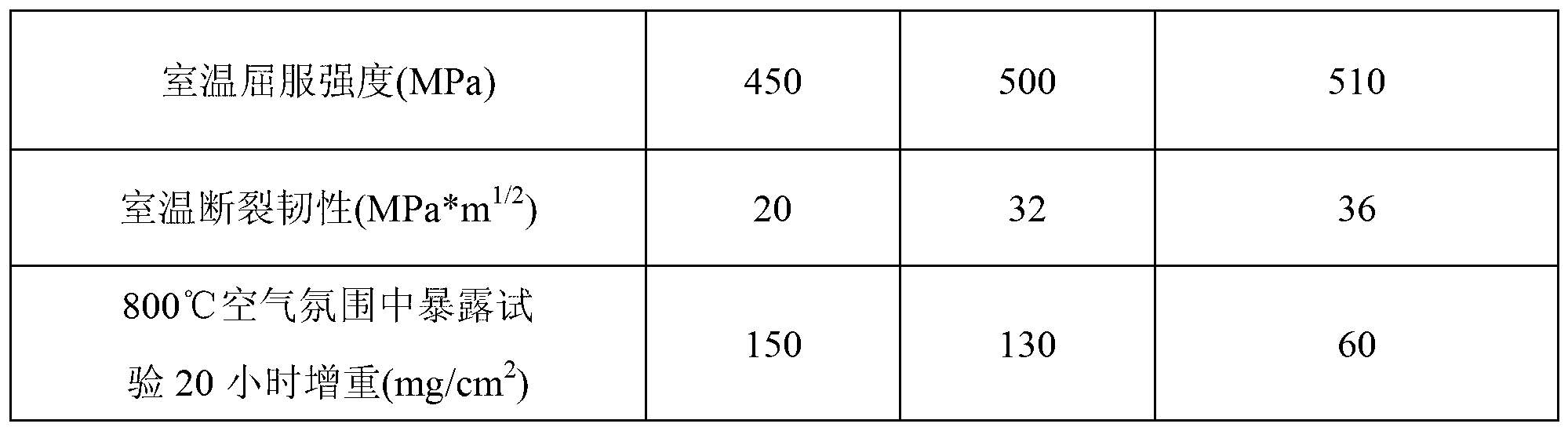

Embodiment 1

[0024] (1) Using pure titanium, pure aluminum, pure niobium, pure carbon, pure silicon, pure tungsten, and pure yttrium (all with a purity of 99.99%) as raw materials, according to Ti 45 Al 45 Nb 5 C 0.5 Si 0.1 W 1 Y 0.1 The composition ratio of the material is weighed.

[0025] (2) Put the above-mentioned prepared raw materials into an electric arc melting furnace, evacuate to 0.01Pa, fill with high-purity argon to 600Pa, and then melt under the conditions of an electric arc melting furnace current of 200A and a voltage of 2V to prepare The composition is Ti 45 Al 45 Nb 8 C 0.5 Si 0.1 W 1 Y 0.1 button ingots, weighing 20g.

[0026] (3) Put the button ingot prepared above into the suspension smelting furnace, evacuate to 5Pa, fill it with high-purity argon to 0.03MPa, and then use a quartz tube with a diameter of Ф4mm under the condition of the suspension smelting furnace power of 20KW Suction casting, the prepared composition is Ti 45 Al 45 Nb 8 C 0.6 Si 0....

Embodiment 2

[0030] (1) Using pure titanium, pure aluminum, pure niobium, pure carbon, pure silicon, pure tungsten, and pure yttrium (all with a purity of 99.99%) as raw materials, according to Ti 44 Al 46 Nb 7 C 0.8 Si 0.3 W 1.6 Y 0.3 The composition ratio of the material is weighed.

[0031] (2) Put the above-mentioned prepared raw materials into an electric arc melting furnace, evacuate to 0.02Pa, fill with high-purity argon to 630Pa, and then smelt under the conditions of an electric arc melting furnace current of 200A and a voltage of 2V to prepare The composition is Ti 44 Al 46 Nb 7 C 0.8 Si 0.3 W 1.6 Y 0.3 button ingots, weighing 25g.

[0032] (3) Put the button ingot prepared above into the suspension smelting furnace, evacuate to 7Pa, fill it with high-purity argon to 0.04MPa, and then use a quartz tube with a diameter of Ф4mm under the condition of the power of the suspension smelting furnace to be 20KW Suction casting, the prepared composition is Ti 44 Al 45 Nb ...

Embodiment 3

[0036] (1) Using pure titanium, pure aluminum, pure niobium, pure carbon, pure silicon, pure tungsten, and pure yttrium (all with a purity of 99.99%) as raw materials, according to Ti 43 Al 48 Nb 8 C 1 Si 0.5 W 2 Y 0.5 The composition ratio of the material is weighed.

[0037] (2) Put the above-mentioned prepared raw materials into an electric arc melting furnace, evacuate to 0.03Pa, fill with high-purity argon to 650Pa, and then smelt under the conditions of an electric arc melting furnace current of 200A and a voltage of 2V to prepare The composition is Ti 43 Al 48 Nb 8 C 1 Si 0.5 W 2 Y 0.5 button ingots, weighing 30g.

[0038] (3) Put the button ingot prepared above into the suspension smelting furnace, evacuate to 10Pa, fill with high-purity argon to 0.05MPa, and then use a quartz tube with a diameter of Ф4mm under the condition of the power of the suspension smelting furnace at 20KW Suction casting, the prepared composition is Ti 43 Al 48 Nb 8 C 1 Si 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com