Integral-structure plastic adjusting bracket

A technology of overall structure and adjusting frame, which is applied in the direction of textiles and papermaking, continuous winding spinning machines, spinning machines, etc. It can solve the problems of affecting the consistency of the tension of the spindle tape, the difference in the consistency of the installation position, and the low manufacturing accuracy. , to achieve the effect of shortening the production cycle, facilitating product installation and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

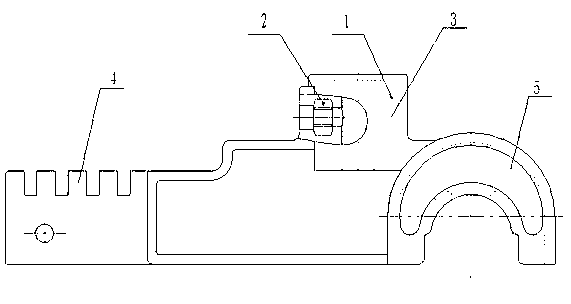

[0008] Such as figure 1 As shown, a plastic adjusting frame with integral structure includes a plastic adjusting frame and a groove plate 4, wherein the plastic adjusting frame includes a plastic adjusting frame body 1, a nut 2, a cylindrical boss 3 and a semicircular convex head 5, and the specification of the nut 2 is GB6170M6×6 hex nut, the nut 2 is set in the hole on one side of the cylindrical boss 3, the plastic adjustment frame body 1 and the nut 2 are integral, the left end of the plastic adjustment frame body 1 is provided with a groove plate 4, the groove plate 4 It is set as a whole with the plastic adjustment frame, and the depth of the groove is 6-8 mm. The material of the plastic adjusting frame body 1 is modified reinforced nylon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com