Synchronous all-in-one machine for automatically pasting ceramic tile and whitewashing wall

An automatic paste, tile powder technology, applied in the direction of construction, building structure, etc., can solve the problems of low work efficiency, incomplete function, waste of time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

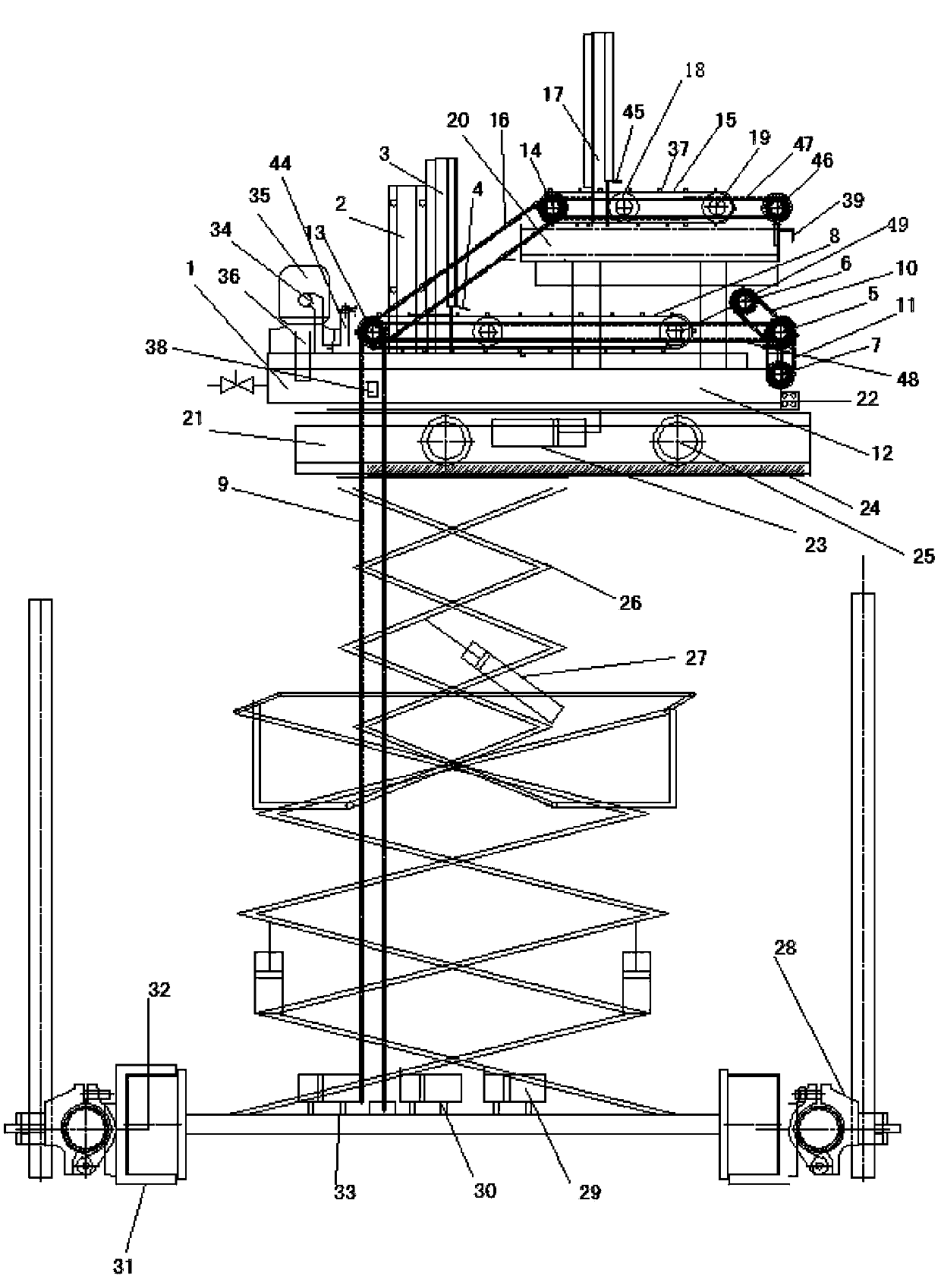

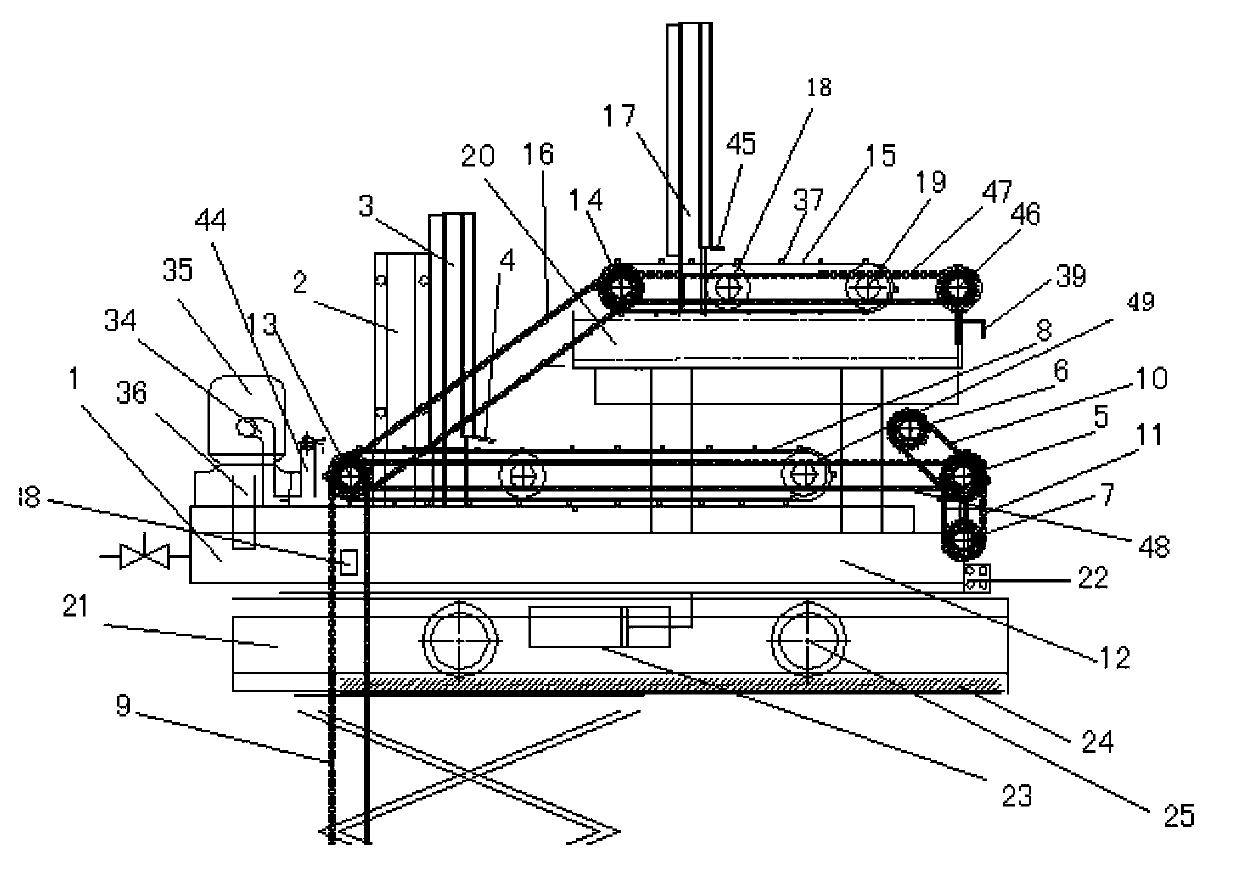

[0039] refer to Figure 1 to Figure 11 , a synchronous all-in-one machine for automatically pasting ceramic tiles and powder walls, including a main machine for pasting tiles, a main machine for powder wall, and a lift arranged under the main machine for pasting tiles and the main machine for powder wall;

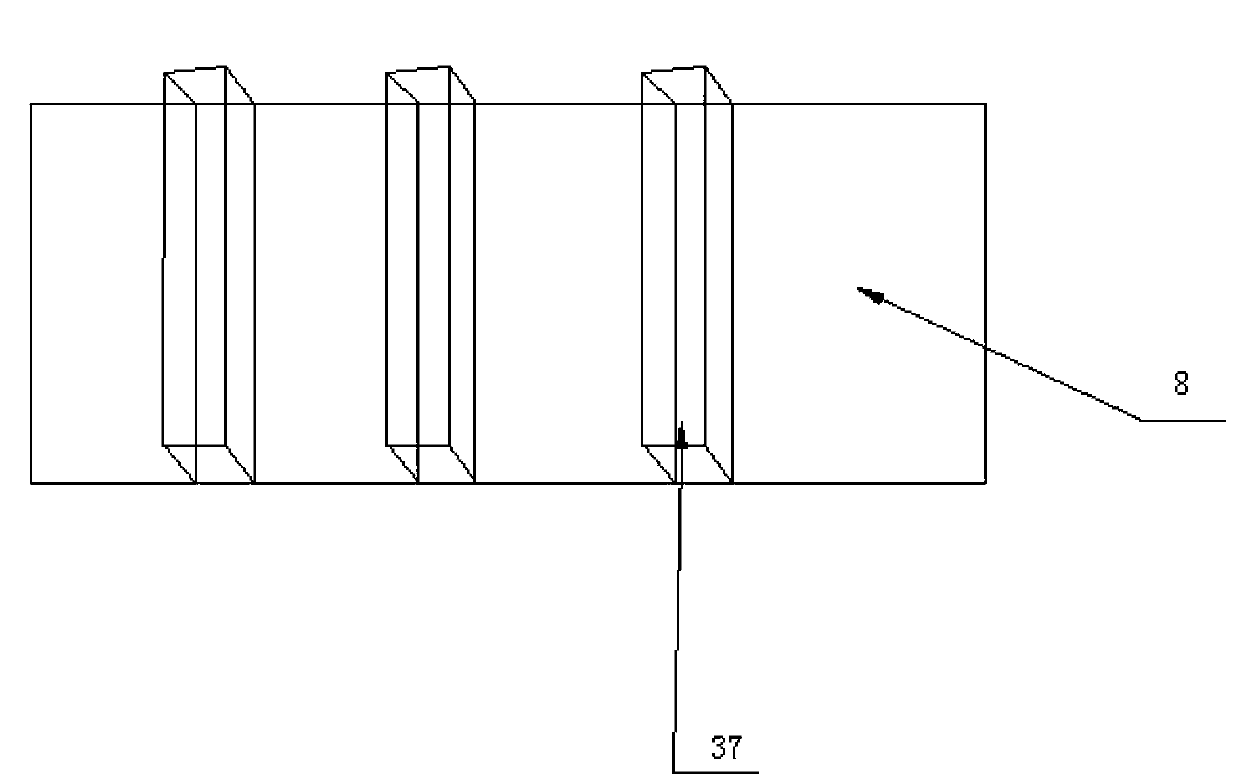

[0040] The main machine for pasting ceramic tiles includes a first frame 1, a first conveying mechanism arranged on the first frame 1 for conveying tiles, and a first plaster that is arranged above the first conveying mechanism and plasters the surface of the tiles. Box 3 and the channel-type tile box 2 for adorning tiles, the first gray board 41 installed on the first frame 1, the rolling tile shaft 5 and the tile stepping shaft 7;

[0041] The powder wall host includes a second frame 20 arranged on the first frame 1, a second conveying mechanism arranged on the second frame 20 for transporting ceramic tiles, and arranged on the first frame 1 The telescopic hydraulic cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com