Double-row ball bearing for liquid crystal lens lapping machine

A double-row ball bearing, liquid crystal lens technology, applied in the directions of bearings, bearing components, shafts and bearings, can solve the problem of inability to achieve high precision, achieve high axial configuration, withstand overturning moment, and improve axial stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

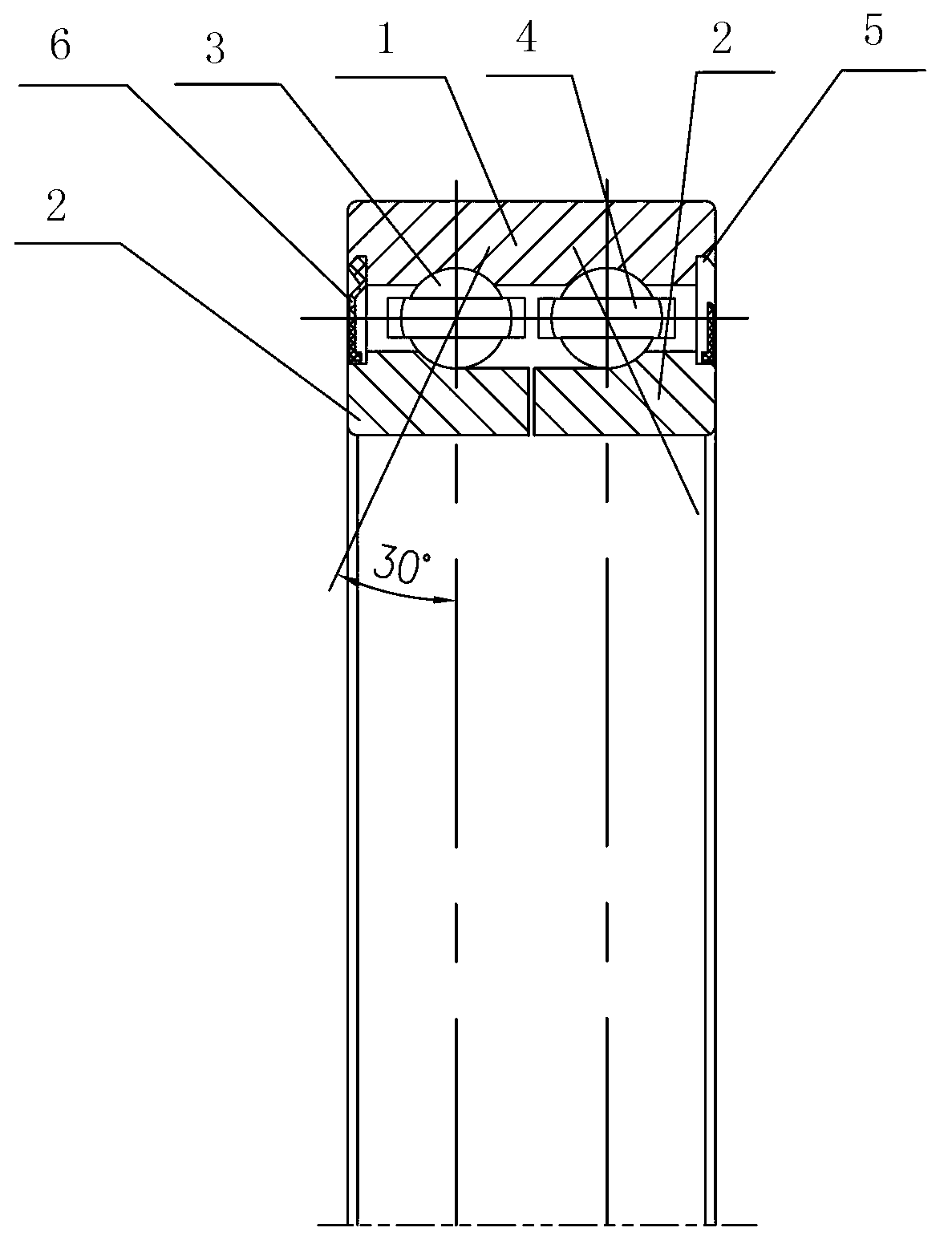

[0011] Such as figure 1 As shown, a double-row ball bearing for a liquid crystal lens lapping machine includes an outer ring 1, an inner ring 2, a steel ball 3 and a cage 4, the inner ring 2 is two, and the inner ring 2 is provided with a steel The ball groove, the two inner rings 2 are placed side by side in the axial direction so that the two steel ball grooves are symmetrical to the center, steel balls 3 are placed in the steel ball groove, the steel balls 3 are evenly separated by the cage 4, and the outer side of the steel ball 3 is sleeved Two sealing grooves 5 are arranged on the inner end surface of the ring 1 and the outer ring 1, and a sealing ring 6 is fixed in the sealing groove 5, and the inner diameter of the sealing ring 6 is in clearance fit with the outer diameter of the inner ring 2.

[0012] The outer ring 1 adopts a double row channel structure.

[0013] The distance between the centers of the channels of the outer ring 1 is 28 mm, forming a fixed axial mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com