A Continuous Fiber Laminate with Variable Stiffness Composite

A composite material and continuous fiber technology, applied in the field of composite materials, can solve problems such as the unevenness of composite material layers, achieve broad application prospects and value, reduce manufacturing costs, and improve the effect of axial compression stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

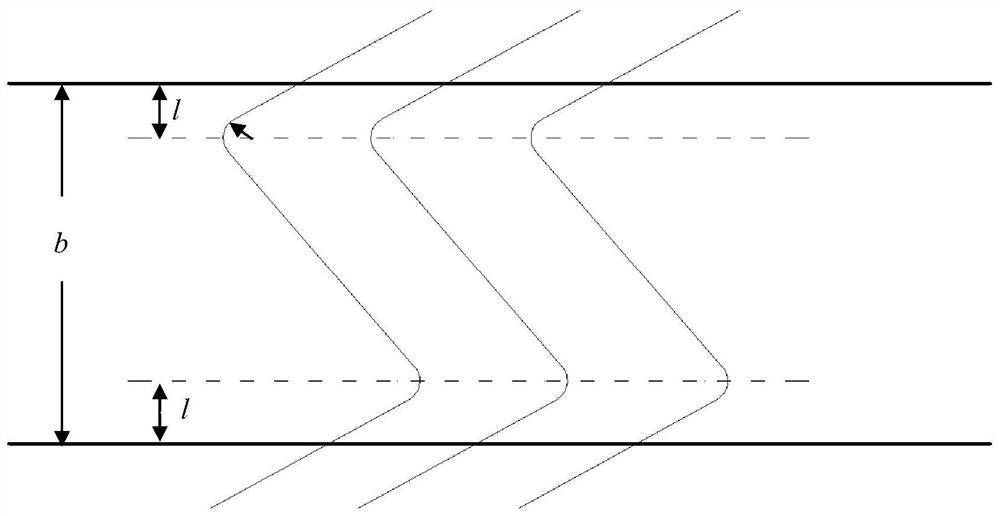

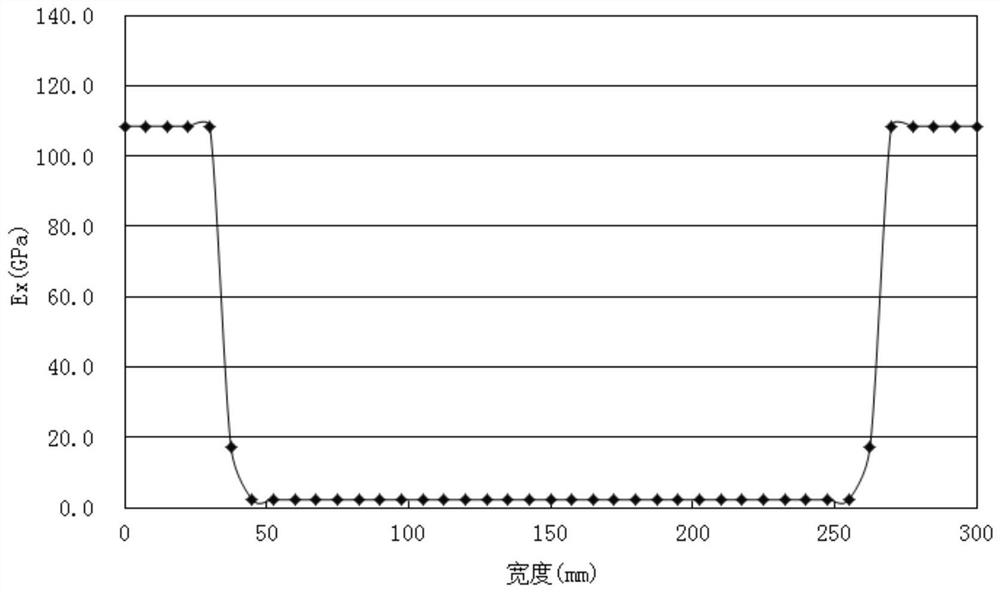

[0022] A continuous fiber variable stiffness composite material layup, which is sequentially woven by a plurality of continuous variable angle fiber bundles, and a single fiber bundle forms a Z-shaped structure after two inflections.

[0023] The angle of the first straight segment (1) and the third straight segment (3) is the same, and the angle of the second straight segment (2) is different from the angle of the first straight segment (1) and the third straight segment (3), so that the same There are two elastic moduli in the layup to realize the change of the in-plane stiffness of the composite laminate structure; the angle between the first straight line segment and the second straight line segment of the fiber bundle and the angle between the second straight line segment and the third straight line segment The included angles are set as: 20-150 degrees.

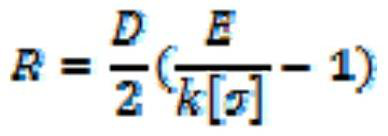

[0024] On the basis of the above structure, the method of setting the fiber inflection radius R is as follows:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com